Machining method for inclined micro hole in outer circle and machining device

A processing device and processing method technology, applied in the field of parts processing, can solve the problems of difficult control of cutting position, easy breakage, inconvenient cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

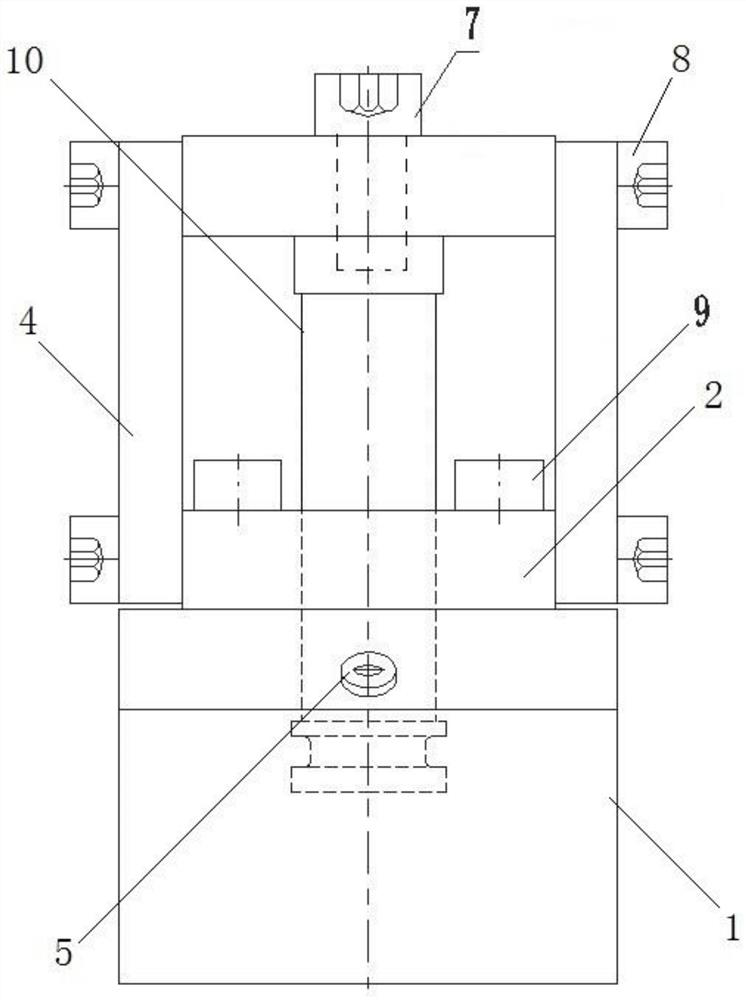

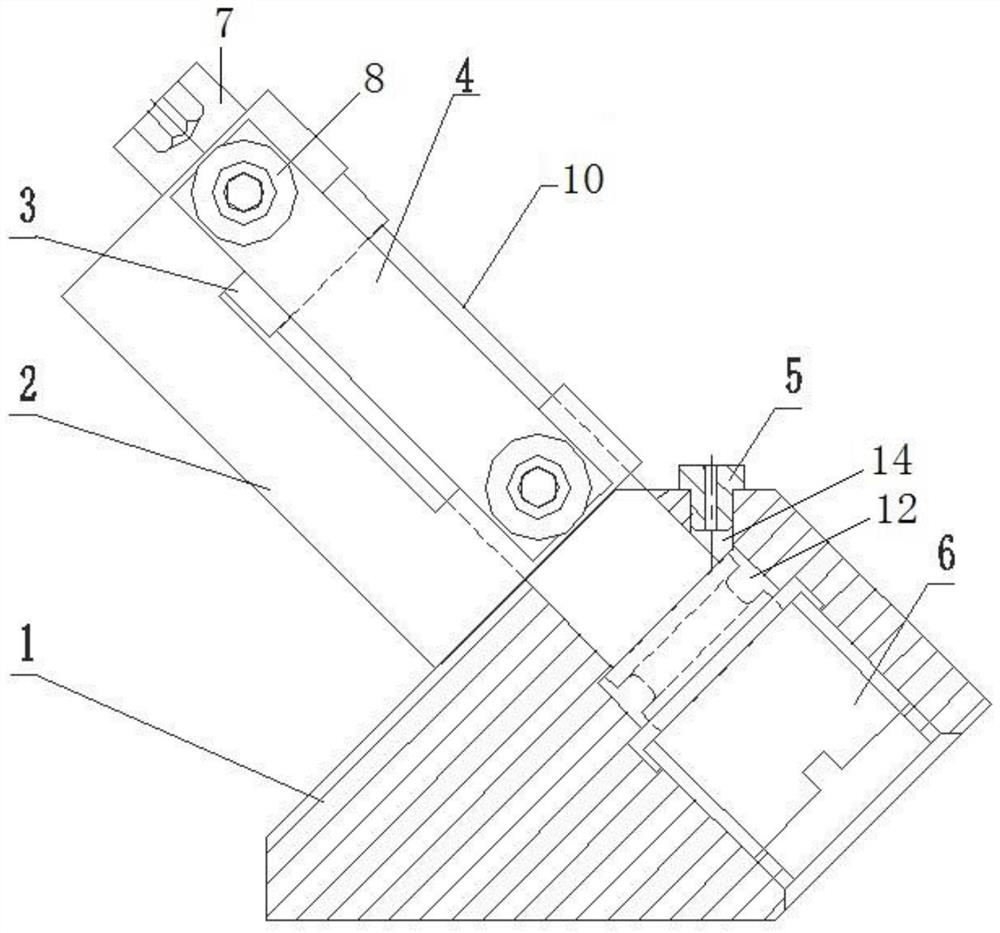

[0024] join Figure 2 to Figure 3 shown.

[0025] A kind of processing method of the oblique tiny hole on the outer circle of the present invention comprises the following steps:

[0026] Step 1: Install the milling cutter on the bench drill Z4006, and adjust the speed to 2000 rpm;

[0027] Place the shim iron on the bench drill workbench, remove the replaceable drill sleeve 5, place the bottom surface of the tooling base 1 on the upper end surface of the shim iron, adjust the position, find the cutting processing position and press the shim iron;

[0028] Fix the compressed air tube in the corresponding position so that the blowing position is at the milling position;

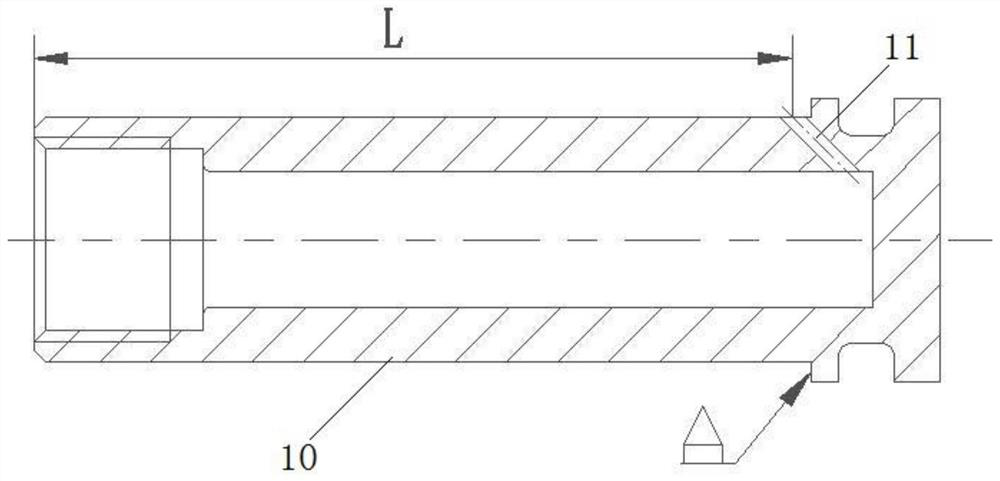

[0029] join image 3 Set the upper, lower, left and right directions, step 2: put the workpiece 10 into the step through hole 12 of the tooling base 1 of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com