Automatic test fixture for frequency converter

A technology for automatic testing and frequency converters, applied to instruments, measuring electronics, measuring devices, etc., can solve problems such as inflexible clamping of frequency converters, easy damage to frequency converters, and unstable testing, so as to prevent inaccurate test data and prevent The effect of excessive extrusion damage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the examples.

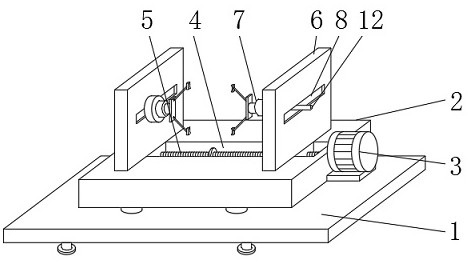

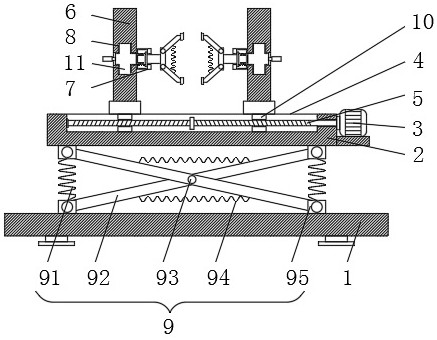

[0020] see Figure 1~3 , in an embodiment of the present invention, an automatic test fixture for a frequency converter, including a base 1, a workbench 2, a buffer device 9 is symmetrically provided between the base 1 and the workbench 2, a motor 3 is installed on one side of the workbench 2, and The middle position of the upper surface of the workbench 2 is provided with a groove 4, and the inner rotation of the groove 4 is installed with a threaded rod 5 fixedly connected with the output end of the motor 3, and the upper surface of the workbench 2 is symmetrically equipped with a movable plate 6, two The bottom of movable plate 6 is fixedly installed with the movable seat 10 that is threadedly connected with threaded rod 5, and the opposite surfaces of two movable plates 6 are all symmetrically equipped with clamping member 7, drives threaded rod 5 to rotate by motor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com