A quick-closing and slow-opening hydraulic priority valve

A slow-opening, priority valve technology, applied in the direction of fluid pressure actuators, servo motor components, components with teeth, etc., can solve the problem of fast opening speed of the main valve, slow mechanical response speed, and lagging main valve closing speed and other problems, to achieve the effects of compact structure, stable and reliable shift speed, and improved system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

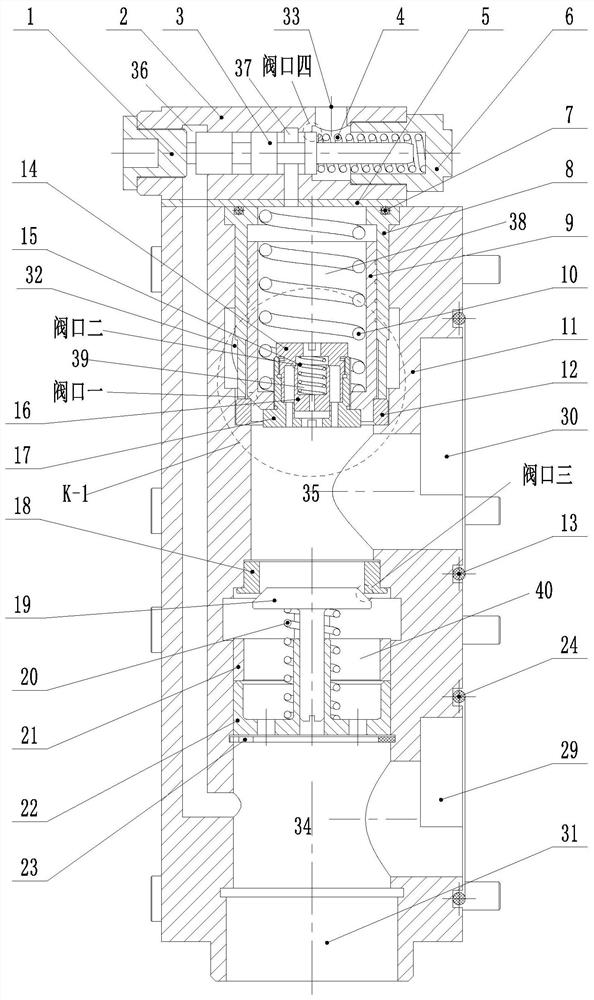

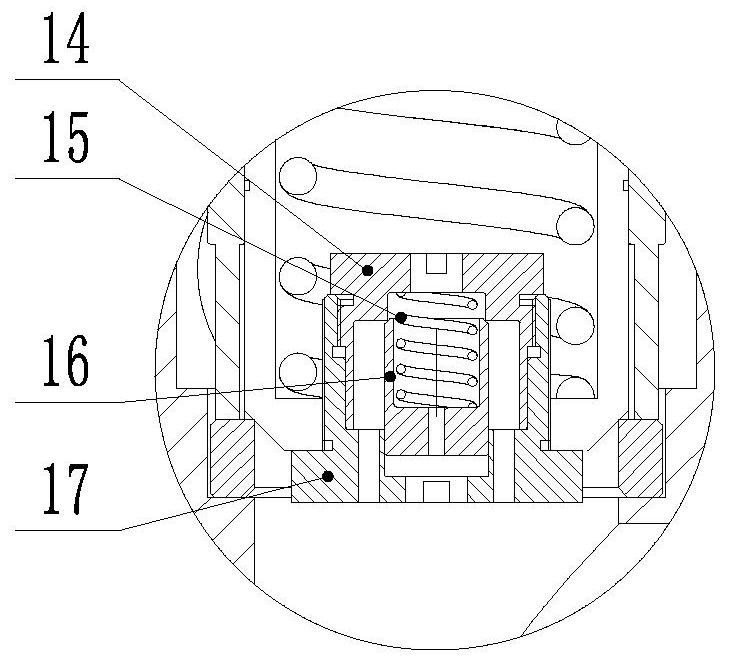

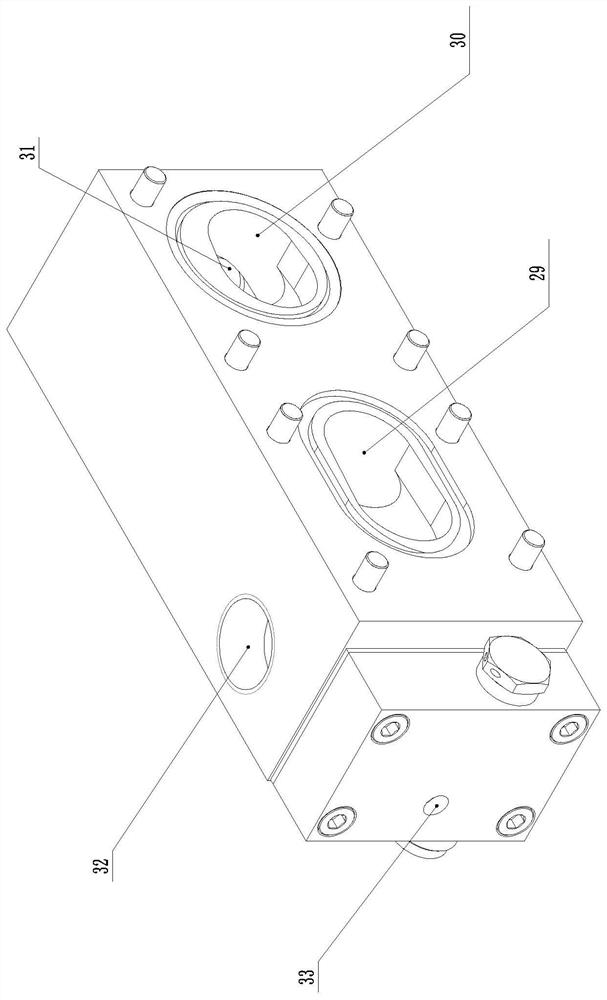

[0017] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-8 , the present invention is described in further detail.

[0018] A fast-closing and slow-opening hydraulic priority valve, including a pilot valve 25, a main valve 26, a speed regulating valve 27 and a one-way valve 28; the pilot valve 25 is installed on the main valve 26, and the speed regulating valve 27 is integrated in the Inside the main valve spool 9 of the main valve 26, the check valve 28 shares a valve body with the main valve 26, and the valve body is provided with an A port 29 connected to the oil supply inlet of the main pump at the main valve 26 and connected to a normal load. The D port 32 of the circuit, the valve body is provided with a B port 30 connected to the oil supply inlet of the auxiliary pump at the check valve 28 and a C port 31 connected to the steering and shift circuit, and the pilot valve 25 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com