Preparation method of cellulosic ethanol

A technology of cellulosic ethanol and lignocellulose, which is applied in the field of cellulosic ethanol preparation, can solve the problems of cumbersome preparation process, waste of resources, high energy consumption and water consumption, and achieve simplified preparation process, saving water and energy consumption, reducing The effect of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

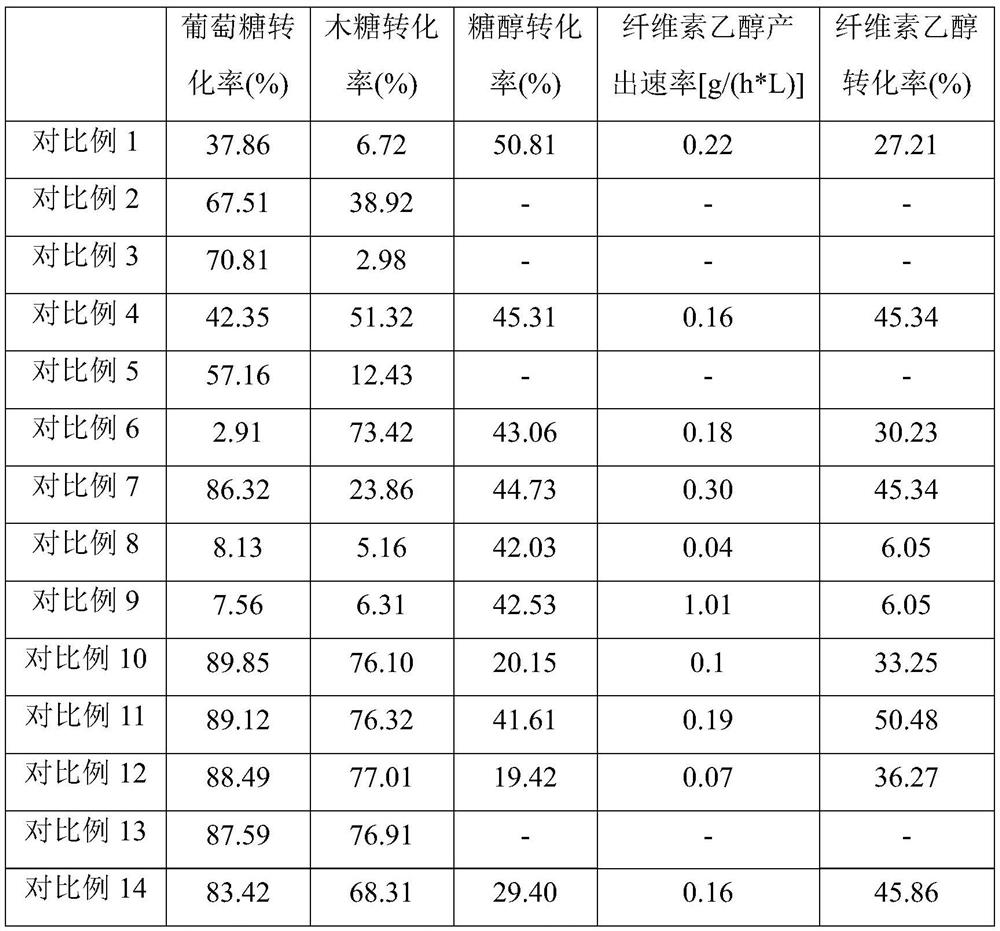

Examples

Embodiment 1

[0047] Embodiment 1 A kind of preparation method of cellulosic ethanol

[0048] S1. Grinding and sieving the bagasse, taking 3g of the crushed bagasse raw material (0.3mm in crushed particle size) and mixing it with 60mL of water (1:20) and putting it in a reactor for reaction at a reaction temperature of 210°C. The reaction time is 0 min, and after the reaction is completed, the mixture is cooled in cold water to obtain bagasse mixture liquid A.

[0049]Wherein, the reaction time is counted from when the temperature is raised to the reaction temperature, and when the reaction time is 0 min, it means that the reaction is stopped immediately when the temperature is raised to the reaction temperature.

[0050] S2. Add the feed liquid A obtained in S1 to a NaOH solution with a concentration of 4mol / L to adjust the pH to 5, and add 36FPU / g 甘蔗渣原料 Cellulase and 7000FXU / g 甘蔗渣原料 Put xylanase in a constant temperature shaker at 50°C for 72 hours of enzymolysis, obtain enzymolysis sol...

Embodiment 2

[0052] Embodiment 2 A kind of preparation method of cellulosic ethanol

[0053] The solution is the same as in Example 1, except that the biomass raw material in step S1 is corn cobs, and the crushed particle size is 0.9 mm.

Embodiment 3

[0054] Embodiment 3 A kind of preparation method of cellulosic ethanol

[0055] Same as the solution in Example 1, except that the biomass raw material in step S1 is rice straw, and the pH in step S2 is 4.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com