Multifunctional light stabilizing composition and preparation method thereof

A composition and photostable technology, applied in the direction of organic chemistry, can solve the problems of degradation of material appearance and mechanical properties, degradation and aging of polymer materials, cracking and stickiness, etc., to increase the scope of use, improve aging resistance, Effect of preventing volatilization and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

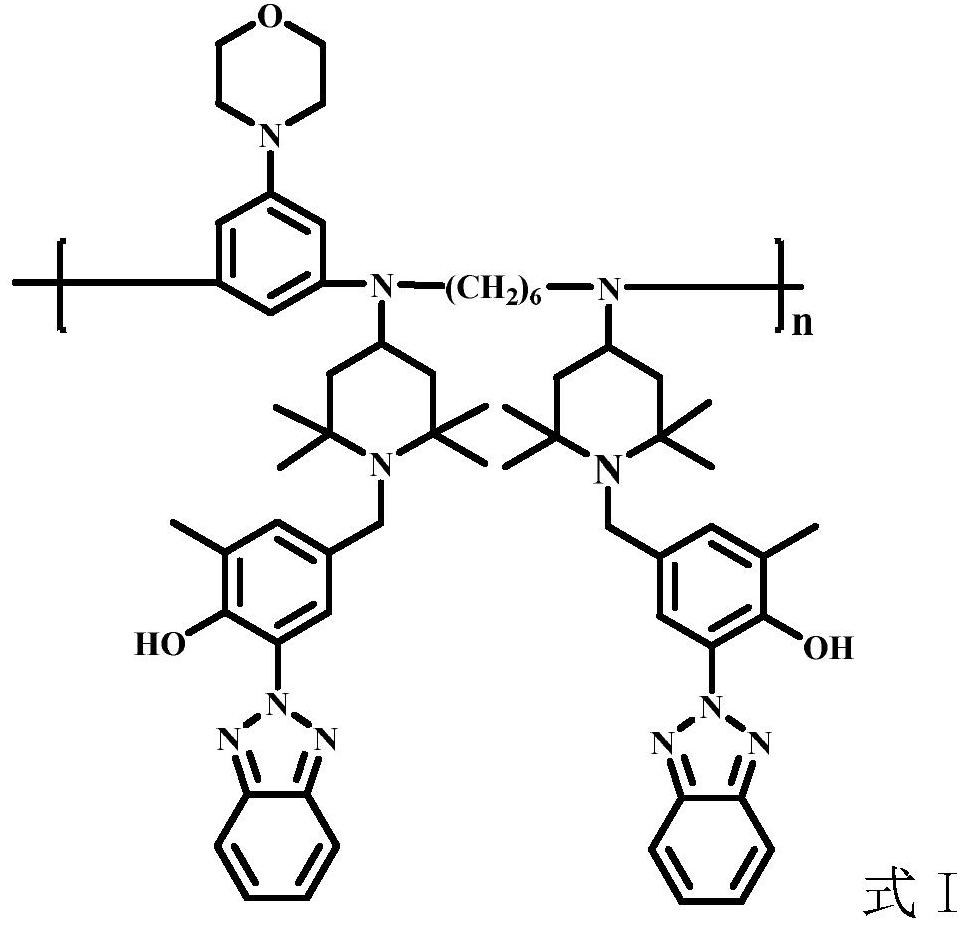

Embodiment i

[0035] Weigh 53.0g of light stabilizer 3346 and dissolve it in 300mL of toluene, and add the above solvent into the autoclave, then add 8g of sodium hydroxide in 100mL of aqueous solution, slowly add 31.8g of 2-(2-hydroxy-5-bromomethyl Base-3-methylphenyl)-benzotriazole 200mL toluene solution, the air in the kettle was replaced with nitrogen three times, the temperature was slowly raised to 110°C, and the reaction was stirred for 16 hours. After the reaction, the water layer was separated, the organic phase was washed 3 times with 100 mL of deionized water, the toluene was evaporated under reduced pressure, and the concentrated solution was naturally cooled to precipitate a light yellow solid I. The measured product number average molecular weight: 2827.

[0036] Example II

[0037] Weigh 53.0g light stabilizer 3346 and dissolve it in 300mL toluene, add the above solvent into the autoclave, then add 100mL aqueous solution of 8g sodium hydroxide, slowly add 63.6g 2-(2-hydroxy-...

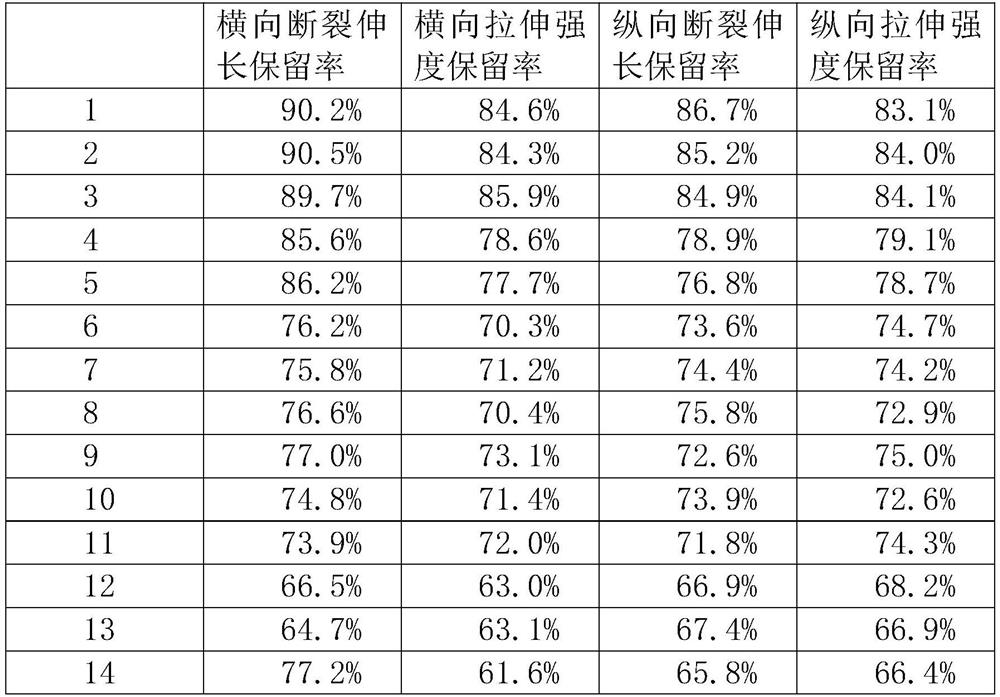

Embodiment 1

[0042] Preparation of composition (1): Take 50 g of the polymer I of Example i, 20 g of bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidinyl) succinate, 2- (2-Hydroxy-3-tert-butyl-5-methoxyphenyl)-benzotriazole 15g, 2-(2-hydroxy-4-octyloxyphenyl)-4,6-bis(2, 12 g of 4-dimethylphenyl)-1,3,5-triazine and 3 g of 2,6-di-tert-butyl-4-methoxyphenol were thoroughly mixed in a ball mill for 30 minutes to obtain composition (1).

Embodiment 2

[0044] Preparation of composition (2): Take 50 g of the polymer I of Example i, 20 g of bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidinyl) succinate, 2- (2-Hydroxy-3-tert-butyl-5-methoxyphenyl)-benzotriazole 15g, 2-(2-hydroxy-4-octyloxyphenyl)-4,6-bis(2, 12g of 4-dimethylphenyl)-1,3,5-triazine and 3g of 2,6-di-tert-butyl-4-methoxyphenol, mix and heat to melt, stir for 10 minutes to mix evenly , cooled and ground to obtain composition (2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com