Preparation method of mesoporous hydroxyapatite microspheres

A technology of mesoporous hydroxyapatite and microspheres, applied in chemical instruments and methods, phosphorus compounds, medical science, etc., can solve the problem that the surface structure of materials cannot be controlled, and the preparation process of mesoporous hydroxyapatite is complicated and cumbersome, etc. problems, achieve low cost, good biological activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

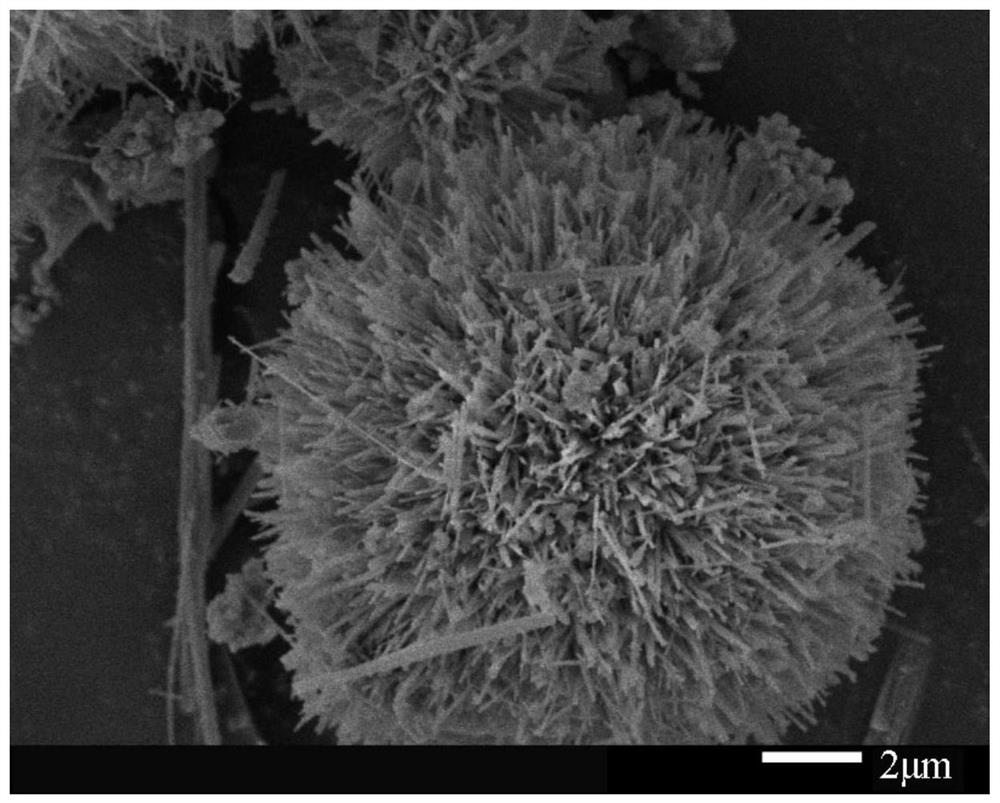

Embodiment 1

[0039] A preparation method of mesoporous hydroxyapatite microspheres, comprising the steps of:

[0040] (1) Calcium nitrate tetrahydrate is dissolved in deionized water to form a 0.1mol / L calcium nitrate solution;

[0041] (2) Diammonium hydrogen phosphate is dissolved in deionized water to be configured as a 0.06mol / L diammonium hydrogen phosphate solution;

[0042] (3) Under stirring, add the diammonium hydrogen phosphate solution obtained in step (2) to the calcium nitrate solution obtained in step (1), add 1% (V / V) phytic acid solution and 1mol / L acetamide , to obtain a mixture;

[0043] (4) Adjust the pH of the mixed solution obtained in step (3) to 2 with 1mol / L nitric acid solution and sodium hydroxide solution, then add it to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and perform a hydrothermal reaction at 180°C for 10 hours; after the reaction, the precipitate was centrifuged and washed, and dried in an oven at 60-80° C. to obtain mesoporous hydr...

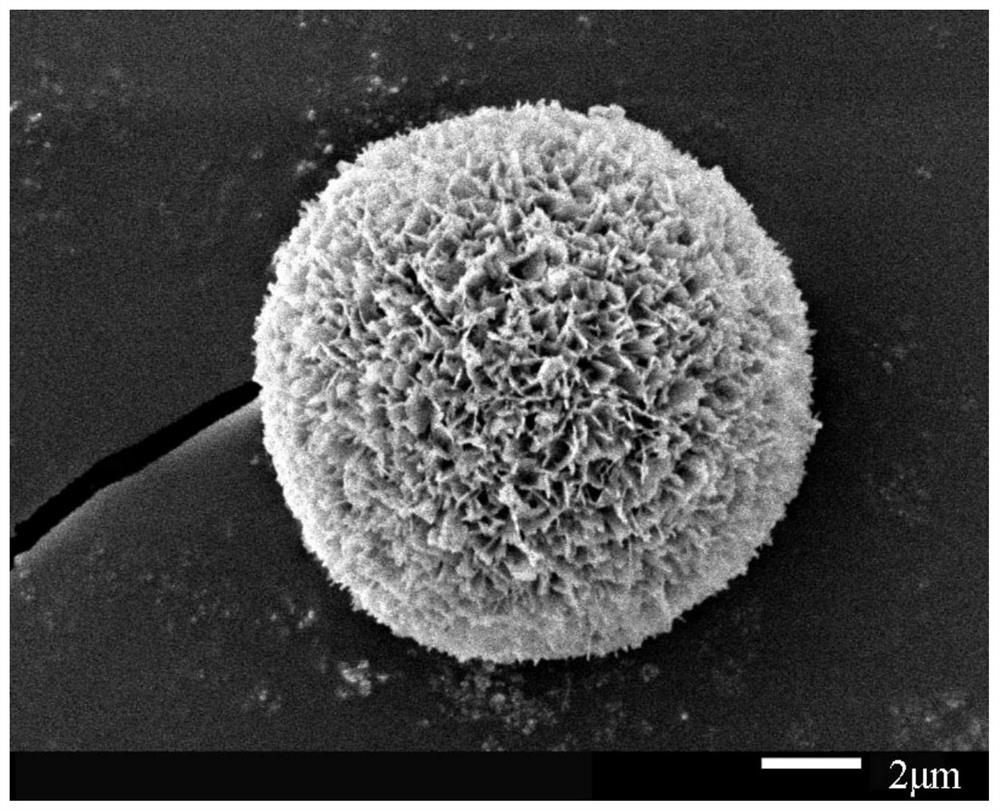

Embodiment 2

[0046] A preparation method of mesoporous hydroxyapatite microspheres, comprising the steps of:

[0047] (1) Calcium nitrate tetrahydrate is dissolved in deionized water to form a 0.1mol / L calcium nitrate solution;

[0048] (2) Diammonium hydrogen phosphate is dissolved in deionized water to be configured as a 0.06mol / L diammonium hydrogen phosphate solution;

[0049] (3) Under stirring, add the diammonium hydrogen phosphate solution obtained in step (2) to the calcium nitrate solution obtained in step (1), add 1.5% (V / V) phytic acid solution and 1mol / L acetamide , to obtain a mixture;

[0050](4) Adjust the pH of the mixed solution obtained in step (3) to 2 with 1mol / L nitric acid solution and sodium hydroxide solution; then add it to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and perform a hydrothermal reaction at 180°C for 10 hours After the reaction, the precipitate is centrifuged and washed, and dried in an oven at 60-80° C. to obtain mesoporous hydro...

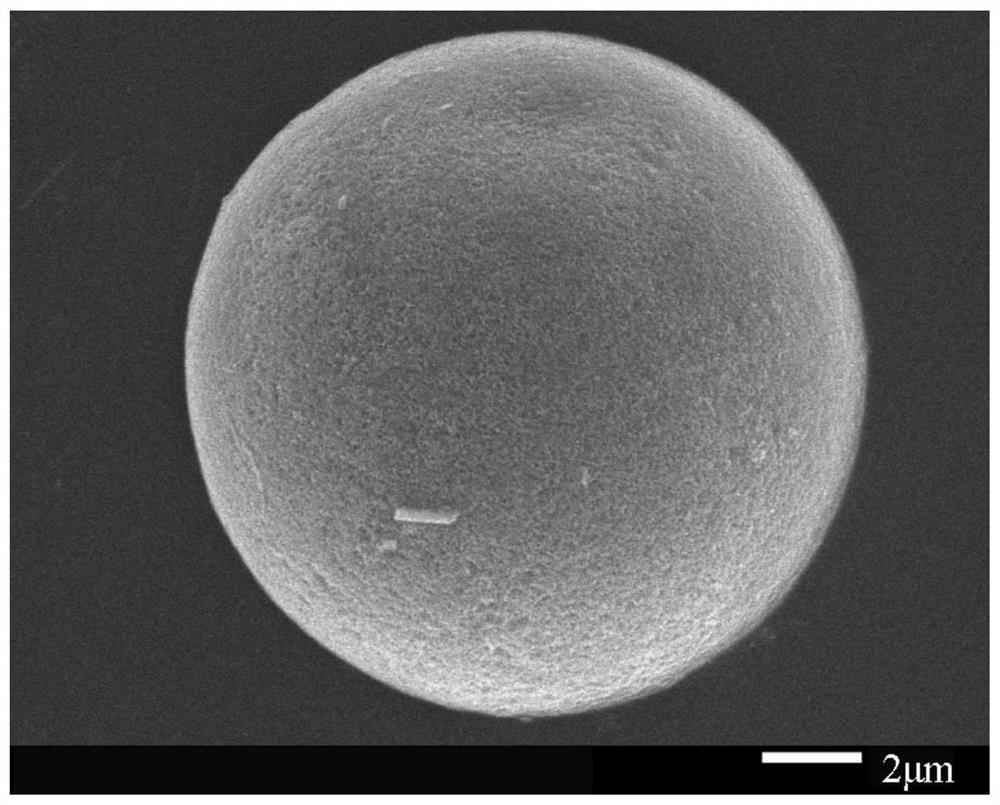

Embodiment 3

[0053] A preparation method of mesoporous hydroxyapatite microspheres, comprising the steps of:

[0054] (1) Calcium nitrate tetrahydrate is dissolved in deionized water to form a 0.1mol / L calcium nitrate solution;

[0055] (2) Diammonium hydrogen phosphate is dissolved in deionized water to be configured as a 0.06mol / L diammonium hydrogen phosphate solution;

[0056] (3) Under stirring, add the diammonium hydrogen phosphate solution obtained in step (2) to the calcium nitrate solution obtained in step (1), add 2% (V / V) phytic acid solution and 1mol / L acetamide , to obtain a mixture;

[0057] (4) Adjust the pH of the mixed solution obtained in step (3) to 2 with 1mol / L nitric acid solution and sodium hydroxide solution; then add it to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and perform a hydrothermal reaction at 180°C for 10 hours After the reaction, the precipitate is centrifuged and washed, and dried in an oven at 60-80° C. to obtain mesoporous hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com