Production method and application of reclaimed sand used for foundry cold cores

A technology of regenerated sand and cold core, which is applied in the direction of casting molding equipment, cleaning/processing machinery of casting mold materials, mold cores, etc. It can solve the problems of oil leakage, engine body is not dense, reduce risk coefficient, etc., and achieve lower melting point , to avoid the effect of insufficient sand core strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

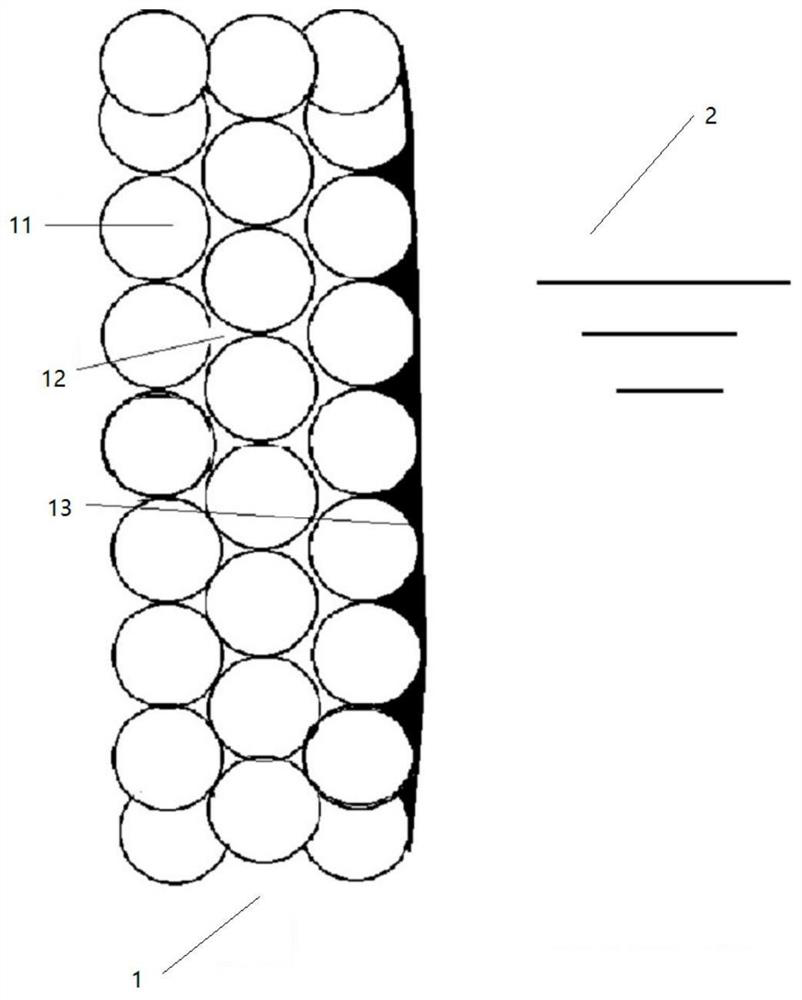

Image

Examples

preparation example Construction

[0029] The preparation method of regenerated sand for foundry cold core provided by the invention comprises the following steps:

[0030] (1) Get langbeinite and dissolve it in water to form an active agent solution;

[0031] Preferably, in step (1), the preparation method of the active agent solvent is as follows: take 11-11 g of langbeinite and add it to 111 mL of water at a temperature of 21-11° C., stir and dissolve to obtain the active agent solution. The activator solution adopted in the present invention is an aqueous solution of langbeinite, which is dissolved in water to form a high-concentration or saturated activator solution for the modification of old foundry sand.

[0032] (2) Take old foundry sand, pre-treat it, then add the active agent solution obtained in step (1) at 111-211° C., and stir at high speed to obtain the regenerated sand.

[0033] Preferably, in step (2), the used foundry sand is organic sand or mixed sand. Preferably, the mixed sand includes or...

Embodiment 1

[0039] A kind of regenerated sand for foundry cold core, its preparation method comprises the following steps:

[0040] (1) Take 11 g of langbeinite and add it to 111 mL of water at a temperature of 11° C., stir and dissolve to obtain the active agent solution;

[0041] (2) Take foundry old sand-organic sand for pretreatment, the pretreatment is thermal old sand regeneration treatment method, specifically including crushing old sand, roasting at 311°C, and particle screening to obtain a particle size of 31-11 mesh Hot sand; then lower the temperature to 111°C, add the activator solution that step (1) obtains, the add-on of activator solute (labeinite) is 1.1wt% of foundry old sand (organic sand) weight, at 611r / min at a high speed for 11 min to obtain the regenerated sand.

Embodiment 2

[0043] A kind of regenerated sand for foundry cold core, its preparation method comprises the following steps:

[0044] (1) Take 11 g of langbeinite and add it to 111 mL of water at a temperature of 21° C., stir and dissolve to obtain the active agent solution;

[0045] (2) Take foundry old sand-organic sand for pretreatment, the pretreatment is thermal old sand regeneration treatment method, specifically including crushing old sand, roasting at 811°C, and particle screening to obtain a particle size of 211-271 mesh Hot sand; then lower the temperature to 211°C, add the activator solution that step (1) obtains, the add-on of activator solute (labeinite) is 1.1wt% of foundry old sand (organic sand) weight, at 1111r / min at a high speed for 11 min to obtain the regenerated sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com