Boron-doped lithium phosphate coated lithium ion battery positive electrode material and preparation method thereof

A positive electrode material and ion battery technology, applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of insufficient lithium phosphate precipitation speed and reaction degree, unfavorable residual lithium control of finished materials, and insufficient lithium ion conduction capacity , to achieve the effect of overcoming the slow precipitation of lithium phosphate, improving the conduction capacity of lithium ions, and enhancing the stability of the surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

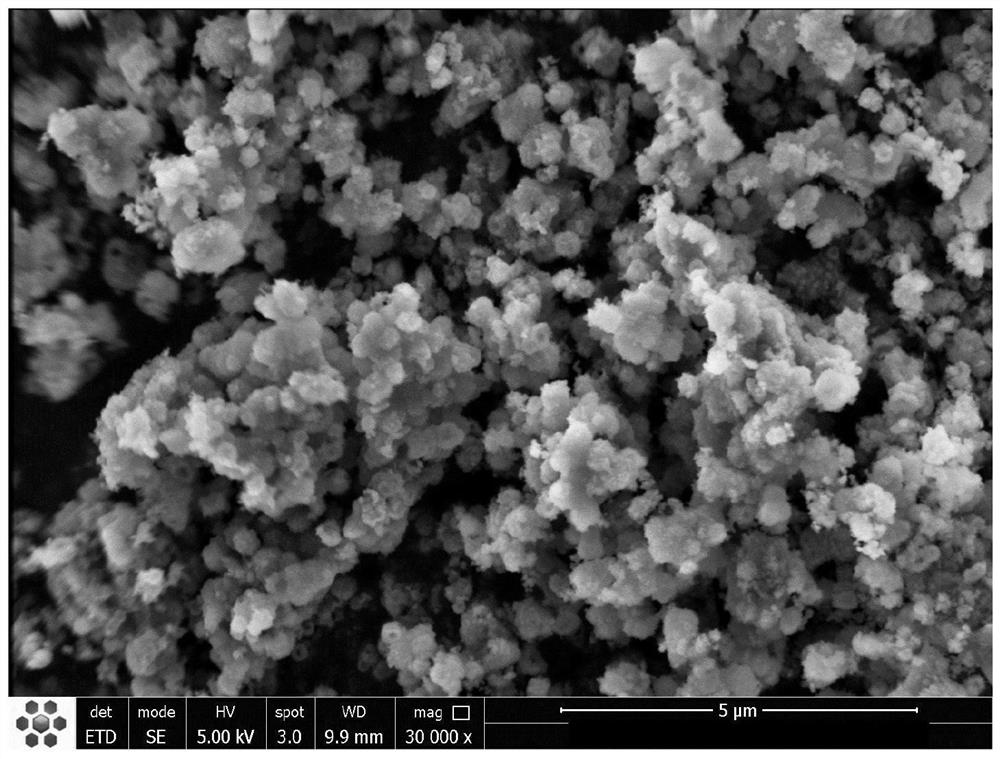

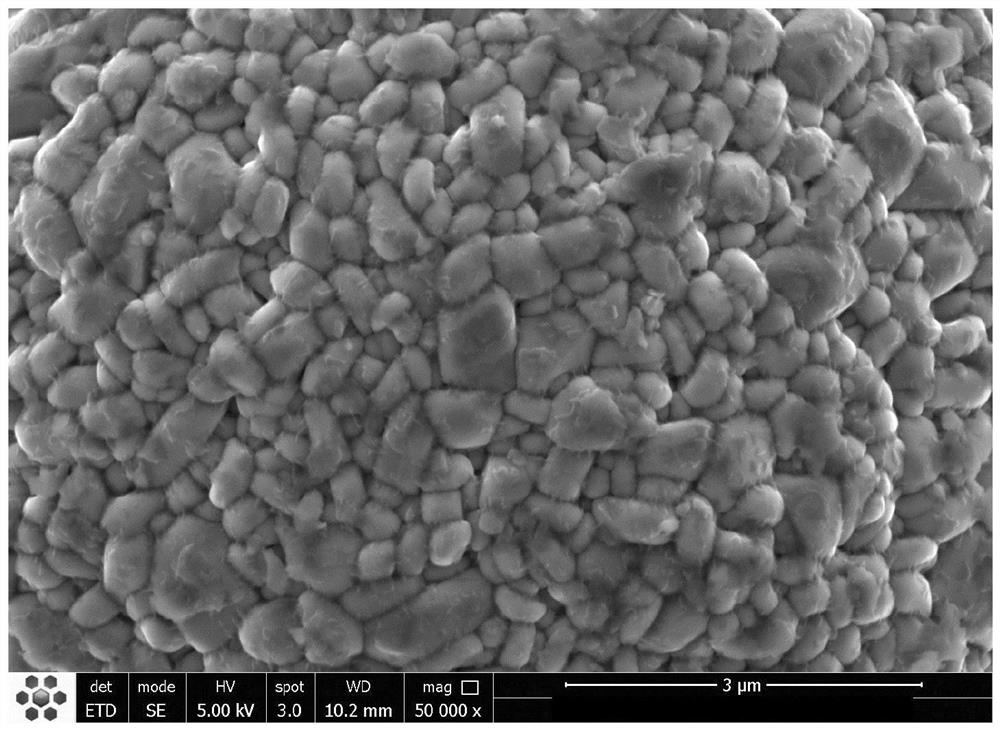

[0036] A kind of boron-doped lithium phosphate of the present invention coats lithium ion battery cathode material, is based on Li 0.980 Ni 0.877 co 0.090 mn 0.030 Zr 0.003 o 2 is the substrate, and the outer surface of the substrate is coated with boron-doped Li 3 PO 4 The cladding layer is based on the total mass of the substrate. The content of phosphorus in the cladding layer is 2590ppm, and the content of boron is 390ppm. The positive electrode material is composed of secondary spherical particles formed by agglomeration of primary particles. D50 is 10.5um.

[0037] The preparation method of the boron-doped lithium phosphate coated lithium-ion battery positive electrode material of the present embodiment comprises the following steps:

[0038] (1) Matrix preparation:

[0039] 500g Ni0.88 co 0.09 mn 0.03 (OH) 2 Precursor and 229.2g lithium hydroxide monohydrate, 2.55g nanoscale ZrO 2 After mixing evenly, feed the oxygen flow rate (50L / min) into the box-type atm...

Embodiment 2

[0051] The preparation process of the boron-doped lithium phosphate-coated lithium ion positive electrode material in this example is basically the same as in Example 1, except that the amount of boron added in step (2) is different, and the other preparation processes are the same. The steps of this example ( 2) In 1.1g of chemically pure H 3 BO 3 Dissolve in 100g deionized water to prepare solution B.

[0052] The remaining lithium test and electrochemical performance evaluation were carried out on the coated positive electrode material prepared in this example.

Embodiment 3

[0054] The preparation process of the boron-doped lithium phosphate-coated lithium ion positive electrode material in this example is basically the same as in Example 1, except that the amount of coating agent in step (3) is different, and the other preparation processes are exactly the same. In this example, step (3) The operation is to "weigh 300g of the base material prepared in step (1) and mix evenly with 1.4g of the coating agent prepared in step (2), and then sinter at a constant temperature of 550°C for 6 hours in an oxygen atmosphere to obtain doped lithium borophosphate Encapsulated cathode materials for lithium-ion batteries".

[0055] The remaining lithium test and electrochemical performance evaluation were carried out on the coated positive electrode material prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com