Method for leaching plutonium in waste resin

A waste resin, weighing technology, applied in sampling, radiation measurement, preparation of test samples, etc., can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with specific embodiments.

[0044] The leaching method of plutonium in the waste resin of the present invention comprises the following steps:

[0045] 1. Sample pretreatment - carbonization, acid leaching

[0046] 1) Weigh 0.10g-0.30g waste resin sample into a 50mL porcelain crucible, cover the crucible, ash in a muffle furnace at 150°C for 2h, take it out and place it at room temperature.

[0047] 2) Add 10mL 3.0mol / L HNO 3 +0.66mol / L HF was leached in a water bath at 90°C for 2 hours, then taken out and placed at room temperature.

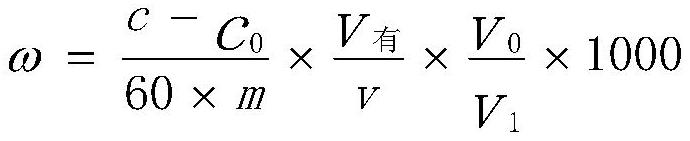

[0048] 3) After filtering the leaching liquid, set the volume to 10 mL, accurately pipette 0.10 mL of supernatant, add 10 mL of scintillation liquid, shake well, and measure on a liquid scintillation counter.

[0049] 4) The leaching rate of plutonium in the waste resin is greater than 97% by calculation.

[0050] 2. Analysis of plutonium activity concentration in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com