Preparation method of spherical particles of potash magnesium sulphate fertilizer

A potassium-magnesium sulfate fertilizer and spherical granule technology, applied in potash fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of product nutrient inconsistency, low particle strength and high particle strength, and prevent the introduction of ineffective components, uniformity and stability. The effect of good fluidity and high particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The embodiments are specifically implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are given. The raw materials involved in the embodiments are all from SDIC Xinjiang Lop Nur Potassium Salt Co., Ltd.

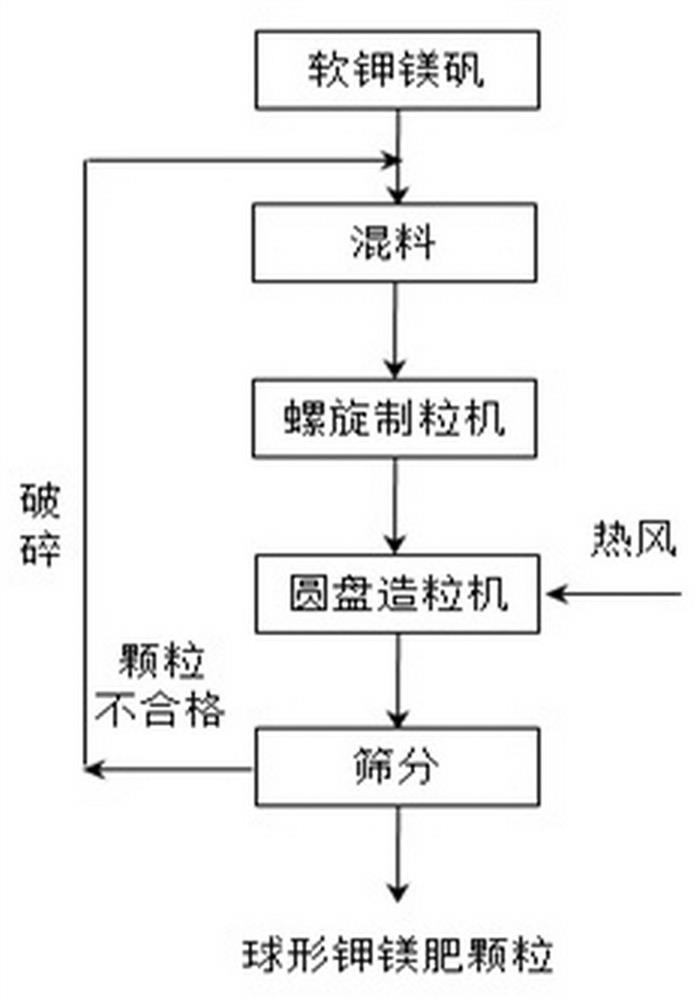

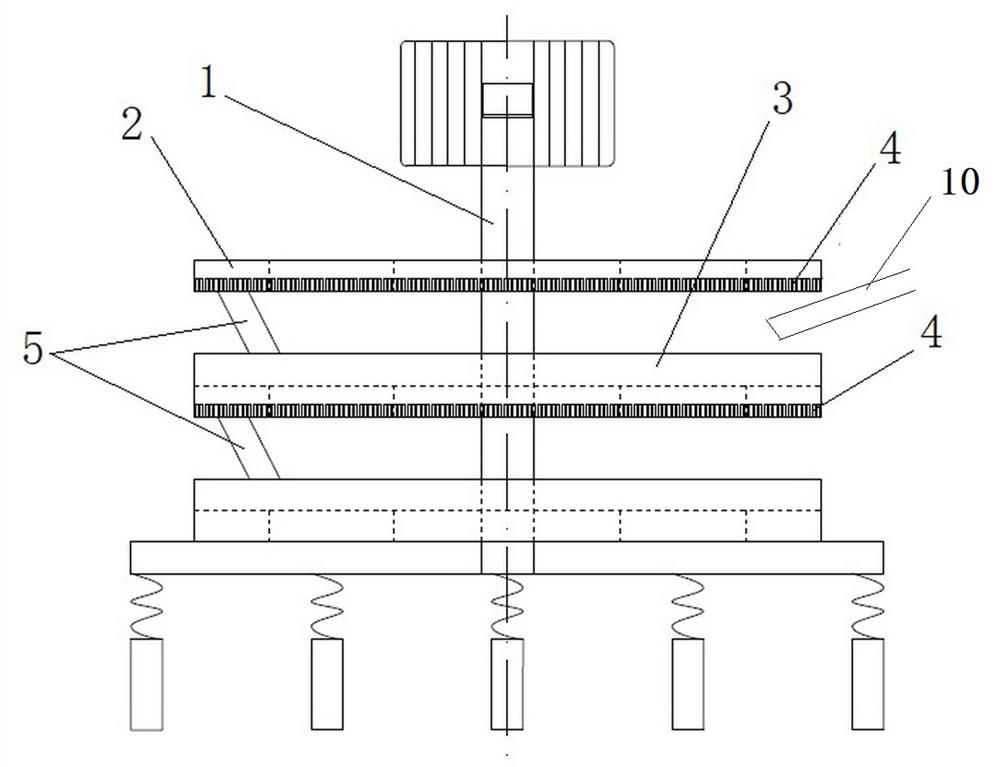

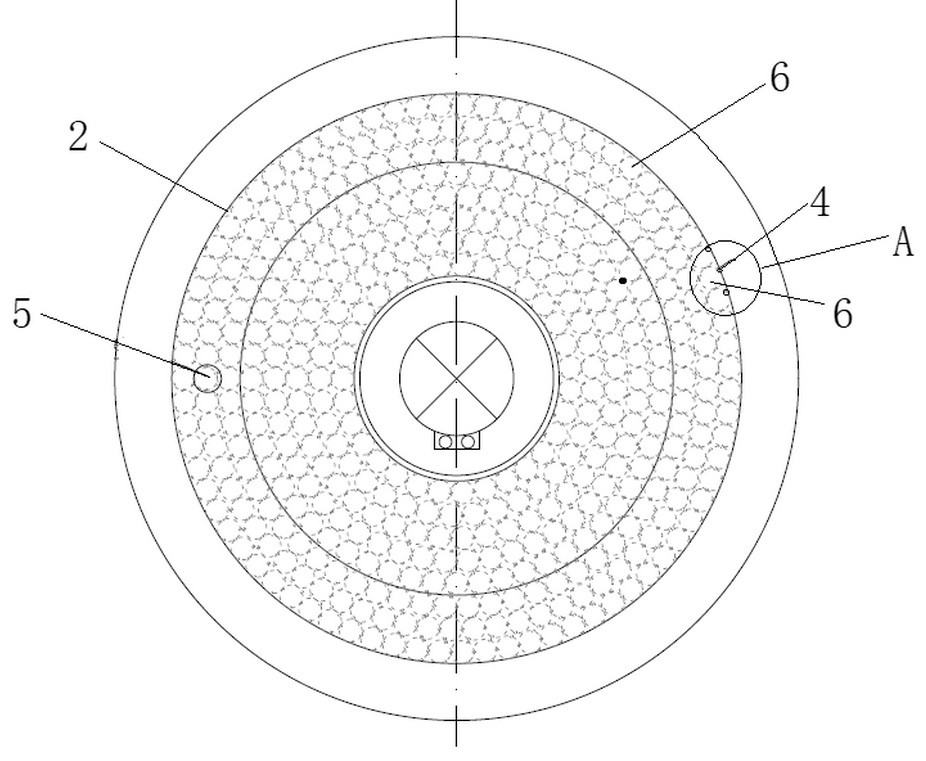

[0016] A kind of preparation method of potassium magnesium sulfate fertilizer spherical particle, implement according to the following steps: as figure 1 , 2 , 3, and 4, take the refined soft potassium magnesium fertilizer with a free water content of about 17%, mix it with the returned material crushed to a particle size of figure 1 Unqualified particles in. Among them, the long pellets with a length of 1-2cm come out from the outlet of the spiral tube shaping machine, and the long pellets enter the disc pelletizer. Such as figure 2 As shown, the disc gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com