A process for deep defluoridation of fluorine-containing water by precipitation and adsorption

A technology of precipitation adsorption and depth, applied in the direction of adsorption of water/sewage treatment, water pollutants, water/sewage treatment, etc., can solve the problems of high cost of adsorption and defluorination, substandard fluoride effluent, unsatisfactory effect, etc., to achieve improvement The effect of fluoride removal, avoiding difficult control, and reducing the effect of solid waste in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

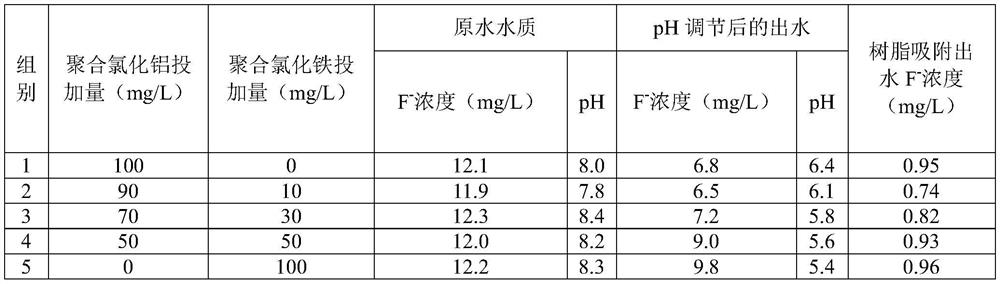

[0035] In the present embodiment, adopt NDA-F-A type resin, respectively adopt polyaluminum chloride of different contents, polyferric chloride, the fluorine-containing waste water of electronics industry to different fluoride ion concentration and pH (waste water is after certain pretreatment, Fluoride ion concentration is lower than 20mg / L) for treatment, the specific treatment steps are as follows:

[0036] S100, at 200r·min -1 Add polyaluminum chloride at a certain stirring rate, and add polyferric chloride 5 minutes later to adjust the pH of the water body; wherein, the overall concentration of the two is 100mg / L;

[0037] S200, after reacting for 3 minutes, reduce the stirring speed to 50r·min -1 , continue stirring for 30 minutes, then stop stirring and settling for 30 minutes;

[0038] S300, introducing the effluent of the supernatant after the pH adjustment and precipitation into the resin adsorption column for adsorption, and the waste water passes through the resi...

Embodiment 2

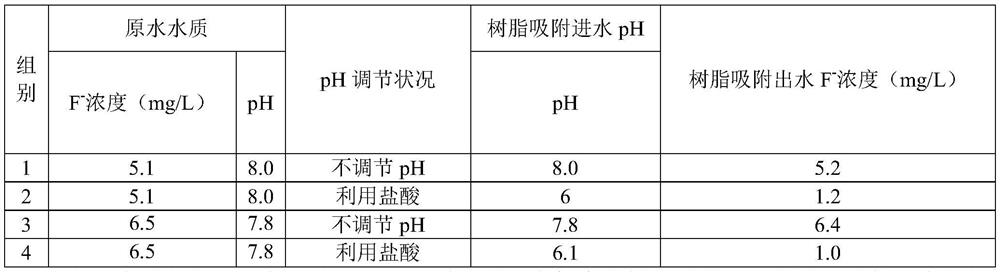

[0044] In this embodiment, adopt NDA-F-A type resin, respectively adopt different coagulants (the content of polyaluminum chloride, polyferric chloride is different), to the fluorine-containing waste water of chemical industry of different fluoride ion concentration and pH (waste water is passed through After certain pretreatment, the fluoride ion concentration is lower than 20mg / L) for treatment, the specific treatment steps are as follows:

[0045] S100, at 200r·min -1 Add polyaluminum chloride at a certain stirring rate, and add polyferric chloride 5 minutes later to adjust the pH of the water body; wherein, the overall concentration of the two is 100mg / L;

[0046] S200, after reacting for 3 minutes, reduce the stirring speed to 50r·min -1

[0047] Continue stirring for 30 minutes, then stop stirring and settling for 30 minutes;

[0048] S300, introducing the effluent of the supernatant after the pH adjustment and precipitation into the resin adsorption column for adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com