Anti-seepage self-healing underground pre-buried cable sheath

A cable sheathing and pre-embedding technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of unfavorable long-term safe use of cables, a large proportion of cable failures, and corrosion of cable insulation layers, so as to achieve long-term safety Use, realize the effect of self-healing ability and low curing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

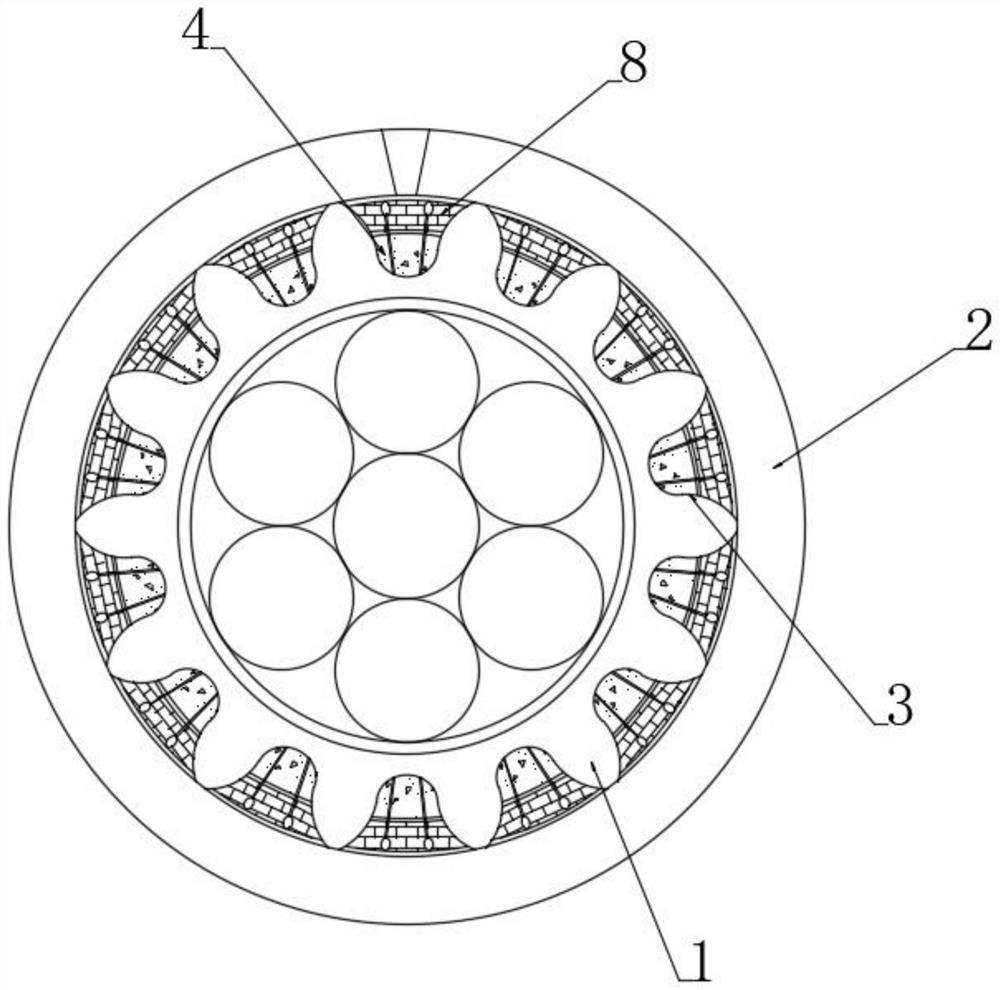

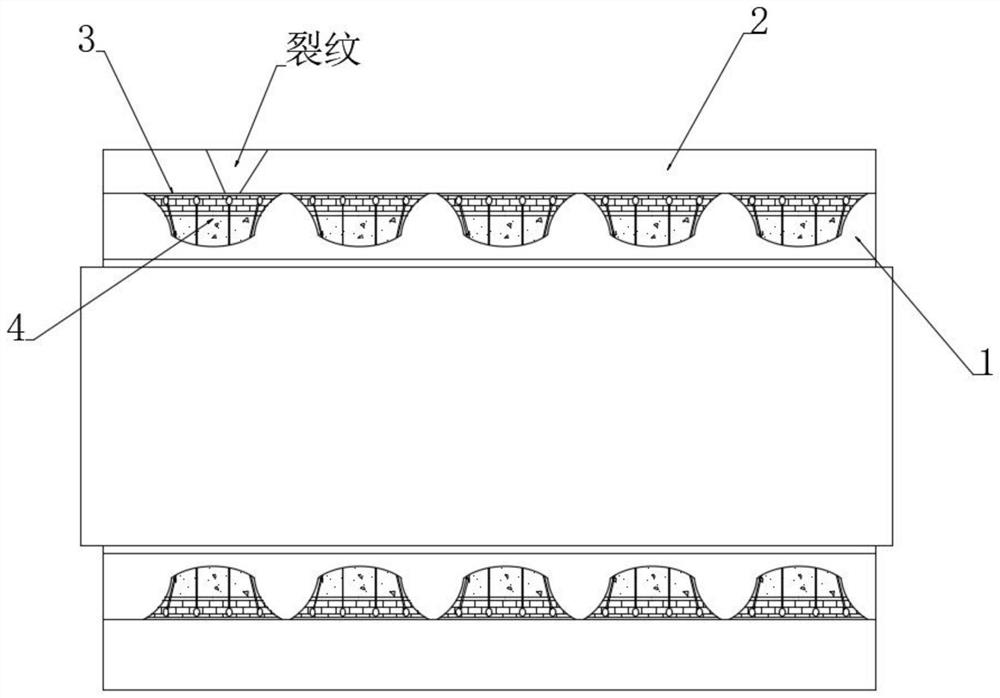

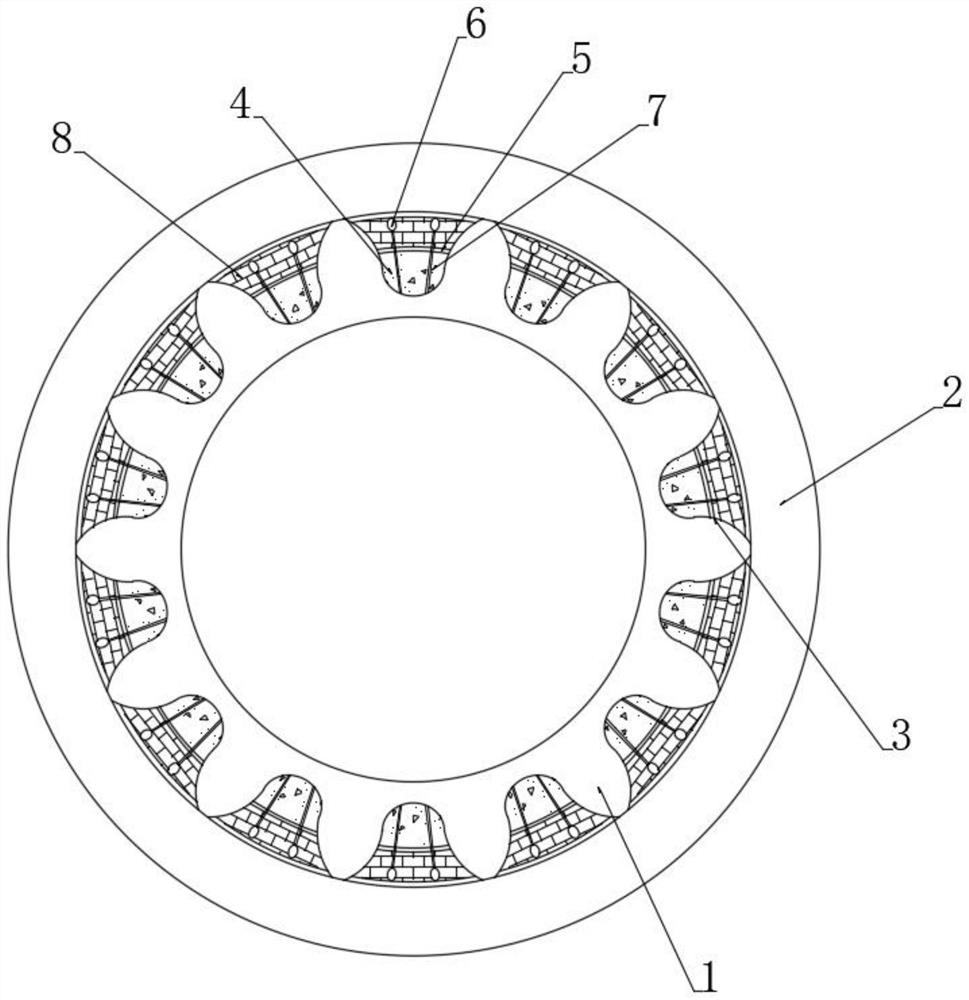

[0045] see Figure 1-5 , an anti-seepage self-healing type underground embedded cable sheath, comprising an inner sheath 1 sheathed on the outer side of the cable insulation layer, the outer side of the inner sheath 1 is covered with an outer sheath 2, the inner sheath 1 and the outer sheath The sleeves 2 are all made of rubber sheath, and the outer wall end surface of the inner sheath 1 is provided with a plurality of repairing material filling cavities 101. The multiple repairing material filling cavities 101 have an elliptical structure with a narrow inside and a wide outside. The cavities 101 are arranged adjacently at the end, and the plurality of repairing material filling cavities 101 are filled with repairing embedded bodies 3, and the outer end walls of the repairing embedded bodies 3 are arranged in sealing connection with the inner end wall of the outer sheath 2, and the repairing embedded The body 3 includes the repairing material 4 filled in the repairing material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com