Polymer film enhanced heat exchange-based waste liquid low-temperature evaporator

A technology of polymer film and low-temperature evaporator, which is applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of waste water odor, smell of waste water, environmental impact, etc., and achieve the purpose of alleviating waste water The effect of backflow, stable gas eruption, and enlarged cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

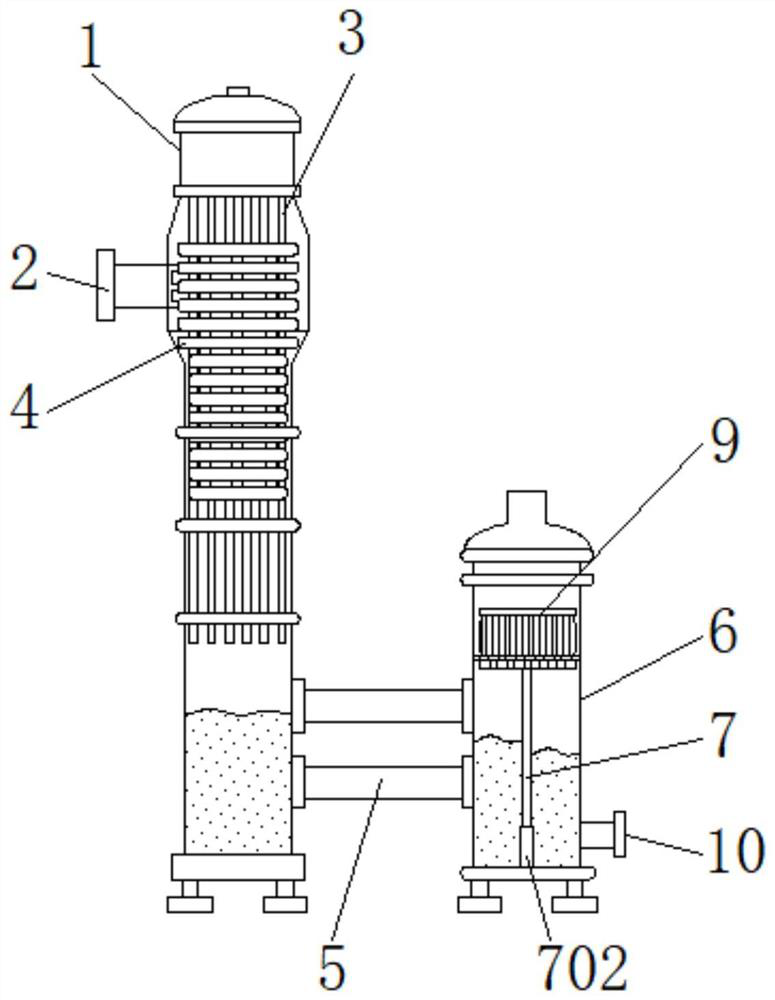

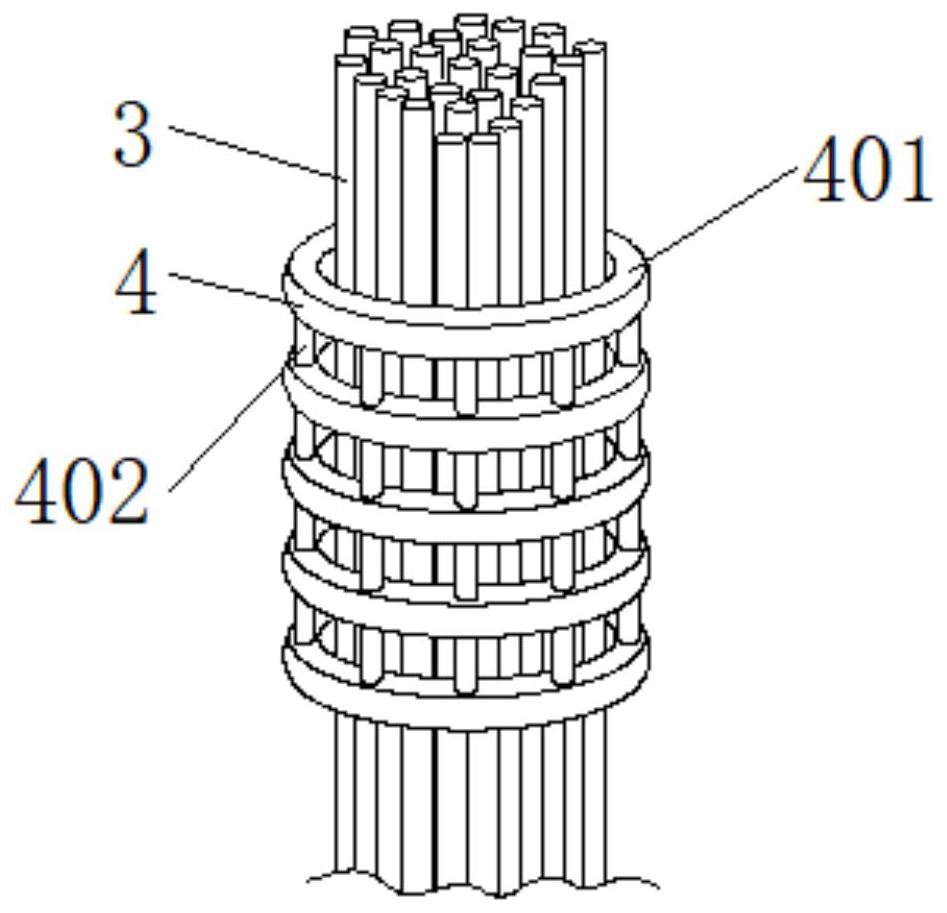

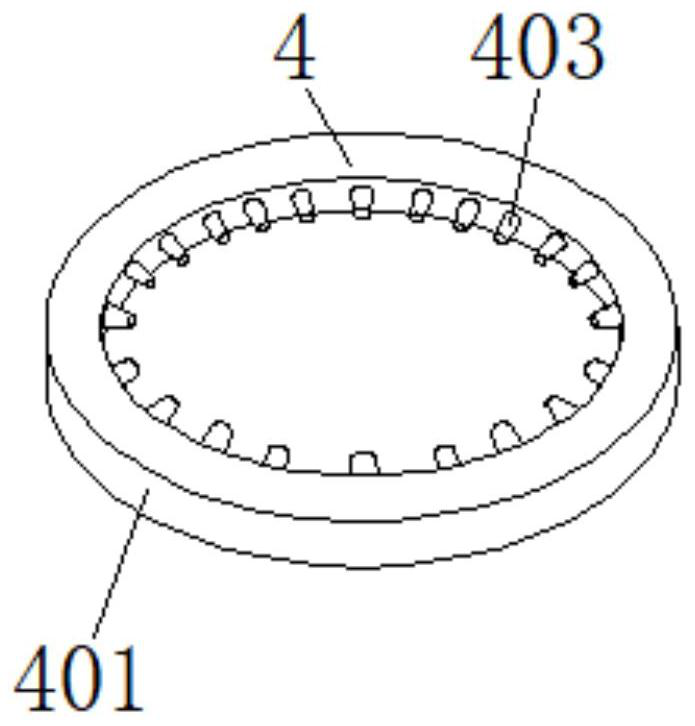

[0026] like Figure 1-Figure 6 As shown, the specific structure of the present invention is: a waste liquid low-temperature evaporator based on polymer film enhanced heat exchange, including a main body 1, an air inlet 2, a thin film tube 3, a cooling mechanism 4, a water pipe 5, a water tank 6, Partition mechanism 7, deodorizing mechanism 8, baffle plate 9 and drain pipe 10, air inlet 2 is installed on one side of the main body 1, and thin film tube 3 is installed inside the main body 1, wherein,

[0027] The outer side of the film tube 3 is wrapped with a cooling mechanism 4, a water pipe 5 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com