Transmission shaft dynamic vibration absorber

A technology of dynamic vibration absorber and transmission shaft, applied in the functional characteristics of spring/shock absorber, design characteristics of spring/shock absorber, spring/shock absorber, etc. The effect of easy adjustment and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

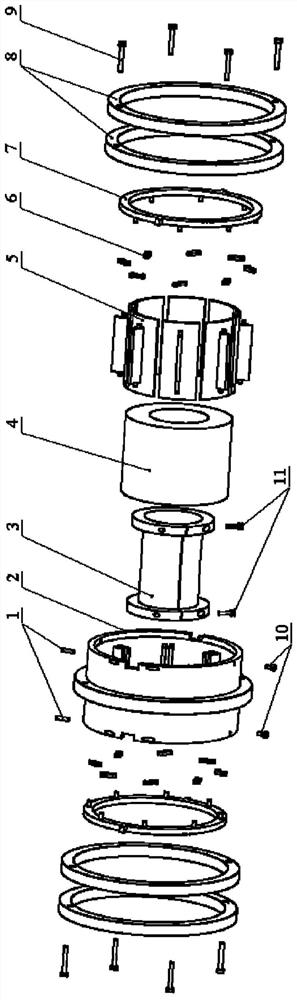

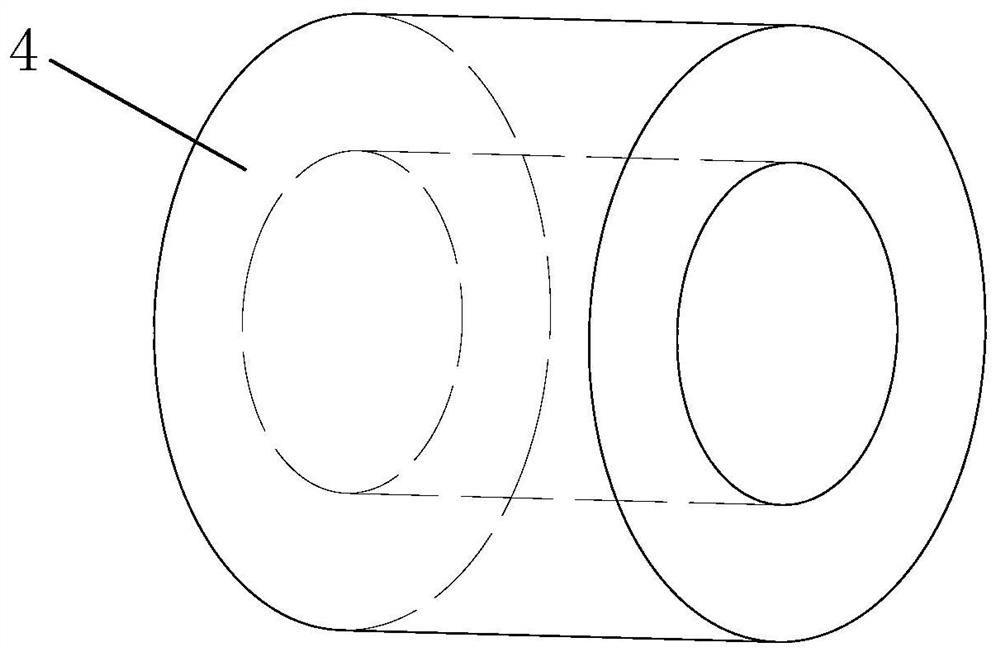

[0026] refer to figure 1 as shown, figure 1 Disclosed is an exploded structure diagram of a drive shaft dynamic vibration absorber according to an embodiment of the present invention. The transmission shaft dynamic shock absorber includes: an outer cylinder 2, an inner cylinder 3, a rubber cylinder 4, a stiffness adjustment mechanism and a counterweight mechanism.

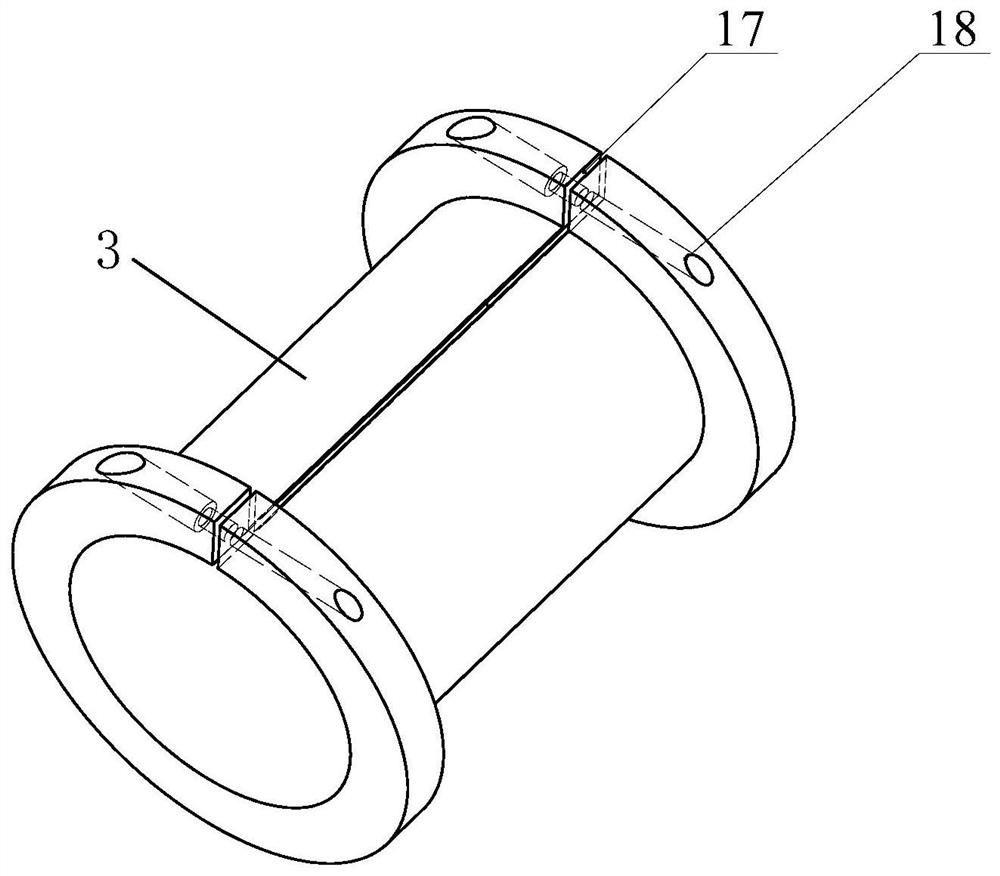

[0027] The inner cylinder 3 is located inside the outer cylinder 2, and the inner cylinder 3 clamps the transmission shaft. figure 2 Disclosed is a structural diagram of an inner cylinder in a drive shaft dynamic shock absorber according to an embodiment of the present invention. combine figure 1 with figure 2 There is a mounting seam 17 parallel to its axis on the inner cylinder 3, and there are clamping screw holes 18 on both sides of the mounting seam 17, and the clamping screw 11 is screwed into the clamping screw hole 18, so that the inner cylinder 3 can clamp the transmission shaft. Loosen the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com