Intensive underground coal and gangue separation system and construction method

A technology of coal gangue separation and construction method, applied in chemical instruments and methods, wet separation, solid separation and other directions, can solve the problems of increasing solid waste pollution, affecting the working and living environment, complex gangue lifting system, etc. Improve the return on investment, facilitate safety management, and promote the coordinated development of resource development and ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

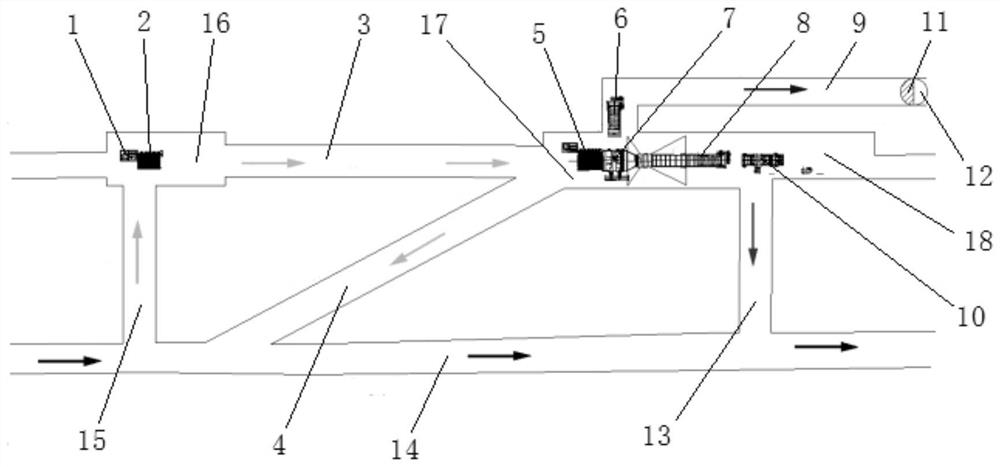

[0039] A construction method for an intensive underground coal-gangue separation system, comprising the following steps:

[0040] 1. Construction of gangue transportation system

[0041] S1. Open the door of the self-separation yard and construct the roadway that runs through the raw coal transportation belt lane 14. The width of the laneway is 3.6m and the height is 3m, forming the clean coal belt lane 13;

[0042] S2. Construction of the washing chamber at the end corresponding to the clean coal belt roadway 13 in the separation and transportation yard, excavation in layers during construction, the width of the roadway is 6.3m, and the height is 7.1m, forming a clean coal processing area 18;

[0043] S3, at the end of the clean coal treatment area 18, push the construction at 0°, the width of the roadway is 6.3m, and the height is 4m, forming a crushing and separation area 17;

[0044] S4. When the construction reaches the position of 7.6m in step S3, push the construction on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com