A kind of biomass building insulation board made of hemp straw

A building thermal insulation and biomass technology, applied in thermal insulation, building components, manufacturing tools, etc., can solve the problems of high thermal conductivity of thermal insulation walls, poor flame retardant effect, poor thermal insulation effect, etc., to promote recycling and good sound insulation effect , enhance the effect of heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

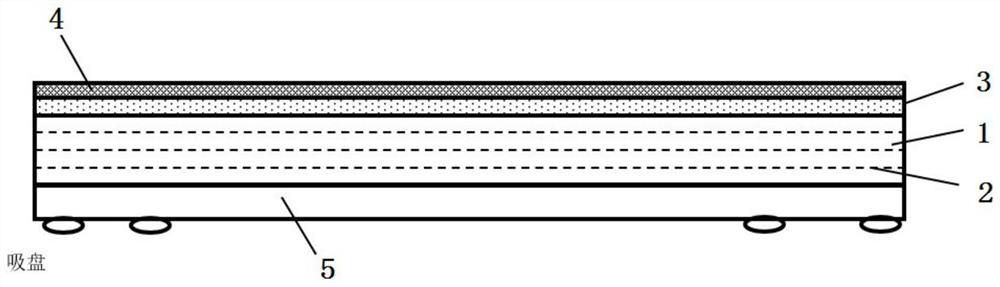

[0039] In this embodiment, an external wall biomass building insulation board made of hemp stalks includes: a biomass insulation layer, an insulation layer panel, an insulation layer backboard and a paint layer, and the biomass insulation layer includes the following components by mass percentage : 30% hemp straw particles, 15% normal temperature closed-cell perlite, 55% kaolin; the coating layer includes the following components: nano-TiO 2 , glass fiber powder, sodium methyl silicate.

[0040] The production method of the building exterior wall biomass insulation board is as follows:

[0041] 1) crushing the hemp stalks with a granulator, and crushing them into 3-10mm particles;

[0042] 2) Soak the straw particles in a flame retardant liquid for flame retardant treatment, and dry them after soaking; the flame retardant is one or more of YF-704Z and UF-705B, and the concentration of the flame retardant liquid is 0.2- 0.3kg / m 3 .

[0043] 3) Mix the flame retardant treate...

Embodiment 2

[0050] In this embodiment, a biomass building insulation board for interior walls made of hemp straws includes: a biomass insulation layer, a coating layer, a sound-absorbing layer and an adhesion layer, and the biomass insulation layer includes the following components by mass percentage: Han Hemp straw particles 50%, normal temperature closed-cell perlite 15%, diatom mud 35%; the coating layer includes the following components: nano-TiO 2 , glass fiber powder, sodium methyl silicate.

[0051] The production method of the biomass insulation board for the inner wall of the building is as follows:

[0052] 1) crush the hemp stalks with a granulator, and crush them into 3-5mm particles;

[0053] 2) Soak the straw particles in a flame retardant liquid for flame retardant treatment, and dry them after soaking; the flame retardant is one or more of YF-704Z and UF-705B, and the concentration of the flame retardant liquid is 0.2- 0.3kg / m 3 .

[0054] 3) Mix the flame retardant tr...

Embodiment 3

[0062] In this embodiment, a biomass building wall material made of hemp stalks includes the following components: 40% hemp stalk particles, 15% closed-cell perlite at room temperature, 20% lime, and 25% kaolin.

[0063] The method of making the building wall material is as follows:

[0064] 1) The hemp stalks are crushed with a granulator, and the granules are crushed into 1-10mm particles;

[0065] 2) Soak the hemp straw particles in a flame retardant liquid for flame retardant treatment, and then dry them;

[0066] 3) Mix the flame retardant treated hemp granules with normal temperature closed-cell perlite, lime and kaolin, and stir evenly;

[0067] 4) Pour an appropriate amount of water into the mixture obtained in step 3), and stir evenly;

[0068] 5) Pour the mixture obtained in step 4) into a forming mold, and dry and form to obtain a building wall material-hemp brick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com