Preparation method of antibacterial and mildew-proof agent for textiles

An antibacterial and antifungal agent and cross-linking agent technology, which can be used in botanical equipment and methods, fungicides, textiles and papermaking, etc. Improve effect time, improve binding performance, avoid elapsed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

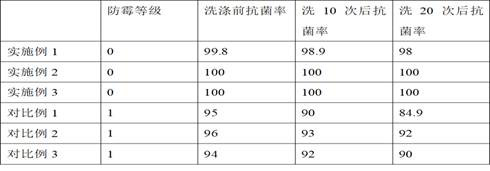

Examples

preparation example Construction

[0028] A preparation method of an antibacterial and antifungal agent for textiles, the preparation method comprising the steps of:

[0029] (1) Mix the composite material and 0.3mol / L hydrochloric acid solution at a mass ratio of 1:10 to 15, maintain the pressure at 2MPa for 70s, steam explode, collect the blasting mixture, and mix the blasting mixture and water at a mass ratio of 3:5 Mix, heat to 100°C, cook for 5-7 hours, cool to room temperature, let stand for 20 minutes, filter, and collect the filtrate;

[0030] (2) Stir and mix the filtrate and activated carbon at a mass ratio of 7:1 to 3, let stand for 1 hour, filter, collect the filtrate, put the filtrate and ethanolamine into the reactor at a mass ratio of 16 to 18:1, and adjust the pH to Neutral, preheat at 50-55°C for 30 minutes, then add a catalyst with 0.1-0.2% ethanolamine mass, raise the temperature to 80-85°C, and stir at 600r / min for 8-10h;

[0031] (3) After the stirring is completed, cool to room temperatur...

Embodiment 1

[0034] The composite material is mixed with honeysuckle, litsea cubeba and Houttuynia cordata in a mass ratio of 10:5:7, and crushed to obtain the composite material.

[0035] The catalyst is a mixture of 1,1'-bisdiphenylphosphinoferrocene palladium dichloride and sodium methoxide at a mass ratio of 4:2.

[0036] The mixture is formed by mixing chitosan and ganoderma polysaccharide in a mass ratio of 20:1.

[0037] The mixed particles are formed by mixing nanoporous titanium dioxide and graphene oxide at a mass ratio of 9:1.

[0038] The crosslinking agent is a mixture of glutaraldehyde and genipin at a mass ratio of 13:1.

[0039] The surfactant is made by mixing polyoxyethylene sorbitan monooleate and sorbitan fatty acid ester at a mass ratio of 8:3.

[0040] A preparation method of an antibacterial and antifungal agent for textiles, the preparation method comprising the steps of:

[0041] (1) Mix the composite material and 0.3mol / L hydrochloric acid solution at a mass ra...

Embodiment 2

[0046] The compound material is mixed with honeysuckle, litsea cubeba and Houttuynia cordata in a mass ratio of 10:4:7, and crushed to obtain the compound material.

[0047] The catalyst is prepared by mixing 1,1'-bisdiphenylphosphinoferrocene palladium dichloride and sodium methoxide at a mass ratio of 4:1.5.

[0048] The mixture is formed by mixing chitosan and ganoderma polysaccharide in a mass ratio of 20:1.

[0049] The mixed particles are formed by mixing nanoporous titanium dioxide and graphene oxide at a mass ratio of 9:1.

[0050] The crosslinking agent is a mixture of glutaraldehyde and genipin at a mass ratio of 13:1.

[0051] The surfactant is made by mixing polyoxyethylene sorbitan monooleate and sorbitan fatty acid ester at a mass ratio of 8:3.

[0052] A preparation method of an antibacterial and antifungal agent for textiles, the preparation method comprising the steps of:

[0053] (1) Mix the composite material and 0.3mol / L hydrochloric acid solution at a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com