Phase change temperature control type silicone rubber composition and preparation method thereof

A silicone rubber composition and a phase-change temperature control technology, applied in the field of silicone rubber, can solve the problems of rising external temperature of electronic products, inability to meet the heat dissipation requirements of high-power electronic components, affecting the reliability of electronic products, and the number of times of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

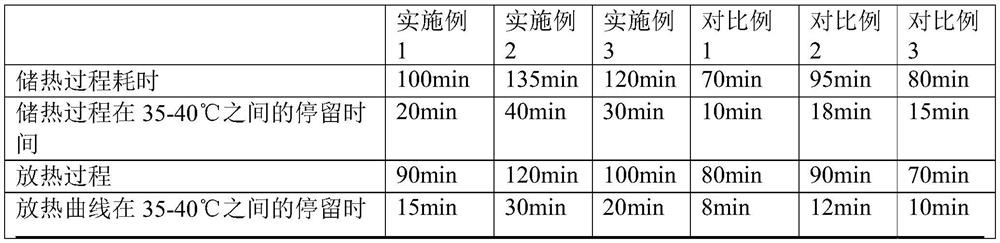

Examples

Embodiment 1

[0044] Preparation method of silicone rubber:

[0045] Step 1) Prepare materials: prepare materials according to the raw material ratio in Table 1, wherein the flame-retardant phase change material is obtained by modifying the porous medium adsorption phase change material and the flame retardant filler through surface modifier, wherein the porous medium adsorption phase change The weight ratio of material and flame retardant filler is 3:2, the specific steps are as follows:

[0046] a. First, put the expandable graphite powder with a specification of 80 mesh and an expansion rate of about 280mL / g in a vacuum oven at 80°C for 12 hours; then put the dried expandable graphite powder in a stainless steel container, and place the stainless steel container in Heat and expand in a high-temperature furnace at 900°C for 45 seconds, take it out and grind it through a high-speed grinder to obtain expanded graphite; mix paraffin wax with a melting point of 35-40°C and the above-mentioned e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com