Modified hydroxyl-terminated polybutadiene as well as preparation method and application thereof

A technology of hydroxyl-terminated polybutadiene and hydroxyl-terminated polydibutene, which is applied in the application field of modified hydroxyl-terminated polybutadiene and its preparation, and preparation of solid propellants, and can solve the problem of single function and adhesive Solve problems such as weak bonding between matrix and filler interface, complex propellant formula, etc., to optimize the preparation process, improve thermodynamic compatibility, and accelerate solid-liquid wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

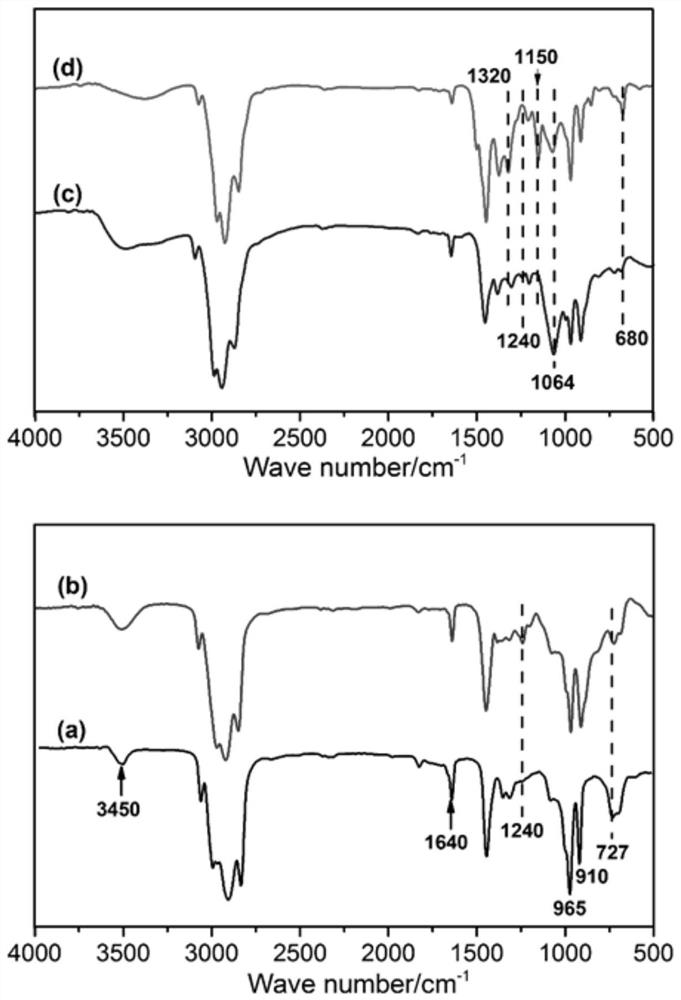

Image

Examples

Embodiment 1

[0052] In this embodiment, the molecular structure of multifunctional modified hydroxyl-terminated polybutadiene (AEHTPB-B) containing ring borate group is as follows:

[0053]

[0054] Wherein, x=44-64, y=2-5, z=3-10.

[0055] The preparation method of the AEHTPB-B of the present embodiment comprises the following specific steps:

[0056] S1. Add 30g of HTPB, 50g of toluene, 15g of glacial acetic acid, and 3g of cationic resin into the reaction vessel, stir evenly and heat up to 60°C; add 75g of H 2 o 2 , and then continue the constant temperature reaction for 8 hours; after the reaction is over, let it stand for stratification, wash the organic layer with distilled water until it is neutral, and at the same time, the washing solution will no longer discolor the starch potassium iodide test paper; A colorless and transparent viscous liquid was obtained, namely EHTPB; the epoxy value of the product was 0.35mol / 100g, and the yield was 97.8%;

[0057] S2. Take 20 g of the ...

Embodiment 2

[0060] The AEHTPB-B molecular structure of the present embodiment is as follows:

[0061]

[0062] Among them, x=44-64, y=2-4, z=3-6.

[0063] The method for preparing the AEHTPB-B of the present embodiment may further comprise the steps:

[0064] S1. Add 30g HTPB, 30g toluene, 30g glacial acetic acid, 1g ammonium tungstate hydrate into the reaction vessel, stir evenly and raise the temperature to 55°C, add 60g H 2 o 2, and then continue the constant temperature reaction for 6 hours; after the reaction is over, let it stand for stratification, wash the organic layer with distilled water until it is neutral, and at the same time, the washing solution no longer discolors the starch potassium iodide test paper; Transparent viscous liquid, epoxidized hydroxyl-terminated polybutadiene (EHTPB). The epoxy value of the product is 0.25mol / 100g, and the yield is 97.9%;

[0065] S2. Take 20g of the EHTPB prepared in step S1 and add it to the reaction kettle, dissolve it with 30g o...

Embodiment 3

[0068] AEHTPB-CN molecular structure is as follows in the present embodiment:

[0069]

[0070] Among them, x=44-58, y=3-5, z=8-10.

[0071] The preparation method of AETHPB-CN in this embodiment comprises the following specific steps:

[0072] S1. Add 30g of HTPB, 30g of toluene, 16g of glacial acetic acid, and 2g of cation exchange resin into the reaction vessel, stir evenly and raise the temperature to 55°C, and dropwise add 75g of H 2 o 2 , and then continue the constant temperature reaction for 7 hours; after the reaction is over, let it stand for stratification, wash the organic layer with distilled water until it is neutral, and at the same time, the washing solution no longer discolors the starch potassium iodide test paper; the organic phase is rotary evaporated under reduced pressure at 90°C to obtain a colorless Transparent viscous liquid, namely EHTPB; the epoxy value of the product is 0.44mol / 100g, and the yield is 97.1%;

[0073] S2. Take 20 g of the EHTPB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com