A kind of synthetic method of stannous ricinoleate

A technology of stannous ricinoleate and synthesis method, which is applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation, etc., and can solve the problems of stannous chloride inability and slow reaction speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

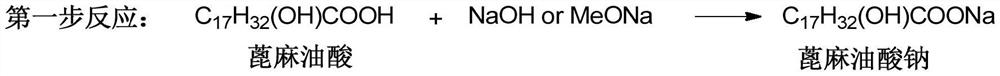

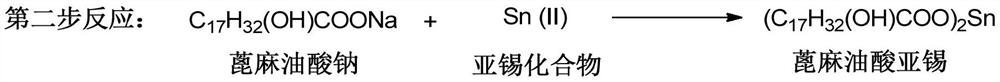

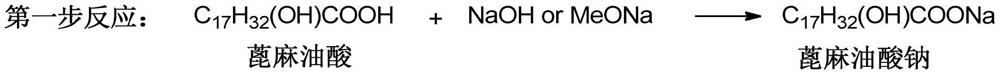

Method used

Image

Examples

Embodiment 1

[0033]

[0034] The first reaction, preparation of sodium ricinoleate: ricinoleic acid (107.4g, 0.36mol) and sodium hydroxide (14.4g, 0.36mol) were added to ethanol (360mL), and the ricinoleic acid molar concentration was 1.0M. The system was stirred for 4 hours at 64°C. After the reaction, the system was a clear system. The reaction solution was collected, and post-processing operation was carried out: the solvent was recovered by distillation under reduced pressure (can be recycled), then vacuum-dried by oil pump, and ground to obtain a pale yellow powdery solid, which was the target product sodium ricinoleate (114.3g), with a yield of 99.0 %.

Embodiment 2

[0036]The reaction steps and operations were the same as those in Example 1, and the difference from Example 1 was that the reaction solvent was methanol (360 mL). The reaction was stopped, and the target product sodium ricinoleate (114.4 g, yield 99.1%) was obtained after post-treatment.

Embodiment 3

[0038] The reaction steps and operations were the same as those in Example 1, and the difference from Example 1 was that the reaction solvent was isopropanol (360 mL). The reaction was stopped, and the target product sodium ricinoleate (114.1 g, yield 98.9%) was obtained after post-treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com