Metal powder for repairing supporting roll based on laser coaxial powder feeding process and preparation method of metal powder

A technology of coaxial powder feeding and metal powder, applied in the direction of additive processing, etc., can solve the problems of increasing demand for surface repair of cold rolls, product surface defects, fatigue wear, etc., achieving long online service life, improving fatigue resistance, reducing Effects of O and N Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] As a kind of implementation mode of the embodiment of the present invention, described back-up roll is made up of the chemical composition of following mass fraction:

[0037] C: 0.4-0.5%, Si: 0.2-0.3%, Mn: 0.2-0.4%, P≤0.02%, S≤0.015%, Cr: 4.5-5.5%, Ni: 0.15-0.82%, Mo: 0.2-0.4 %, V: 0.1-0.2%, the rest is Fe and unavoidable impurities

[0038] In the second aspect, an embodiment of the present invention provides the above-mentioned method for preparing a 3D printing metal powder for repairing backup rollers, the method comprising:

[0039]S1, heat the pre-alloyed rod to 1600-1700°C and melt it, then atomize it under the gas mist pressure of 5-7Mpa to obtain molten droplets; the pre-alloyed rod is composed of the following chemical components in mass fraction: C: 0.4-0.5 %, Si: 0.3-0.5%, Mn: 0.4-0.5%, P≤0.02%, S≤0.015%, Cr: 4.5-5.5%, Ni: 0.15-0.82%, Mo: 0.2-0.4%, V: 0.1 -0.2%, O≤0.03%, N≤0.03%, the rest is Fe and unavoidable impurities;

[0040] S2, after the molten dr...

Embodiment 1

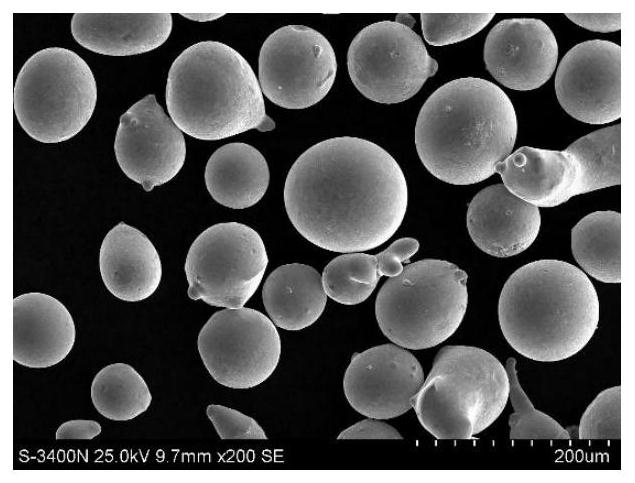

[0051] Example 1 provides a 3D printing metal powder for repairing backup rollers and its preparation method. The chemical composition of the metal powder: C: 0.42%, Si: 0.30%, Mn: 0.43%, P≤0.015%, S: 0.012%, Cr: 4.8%, Ni: 0.35%, Mo: 0.26%, V: 0.11%, O: 0.02%, N: 0.02%, the balance is Fe and unavoidable impurities, the powder particle size is 55-145μm state distribution.

[0052] The preparation method is as follows:

[0053] Lower the slowly selected pre-alloyed rod metal electrode into a ring-shaped induction coil for electrode melting, and the electrode droplet falls into the gas atomization nozzle system, which is atomized with an inert gas to obtain the droplet, which is obtained after cooling the droplet mineral powder. The specific process is shown in Table 1.

Embodiment 2

[0055] Example 1 provides a 3D printing metal powder for repairing backup rollers and its preparation method, the chemical composition of the metal powder: C: 0.44%, Si: 0.35%, Mn: 0.45%, P≤0.016%, S≤ 0.013%, Cr: 5.0%, Ni: 0.53%, Mo: 0.30%, V: 0.15%, O≤0.01%, N≤0.01%, the balance is Fe and unavoidable impurities, and the powder particle size is 52~148μm state distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com