Preparation method of macromolecular semipermeable material

A technology of semi-permeable materials and polymers, applied in the field of polymer semi-permeable materials, can solve the problems of high cost of use, short service life, easy damage, etc., and achieve the effect of long service life, difficult processing and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

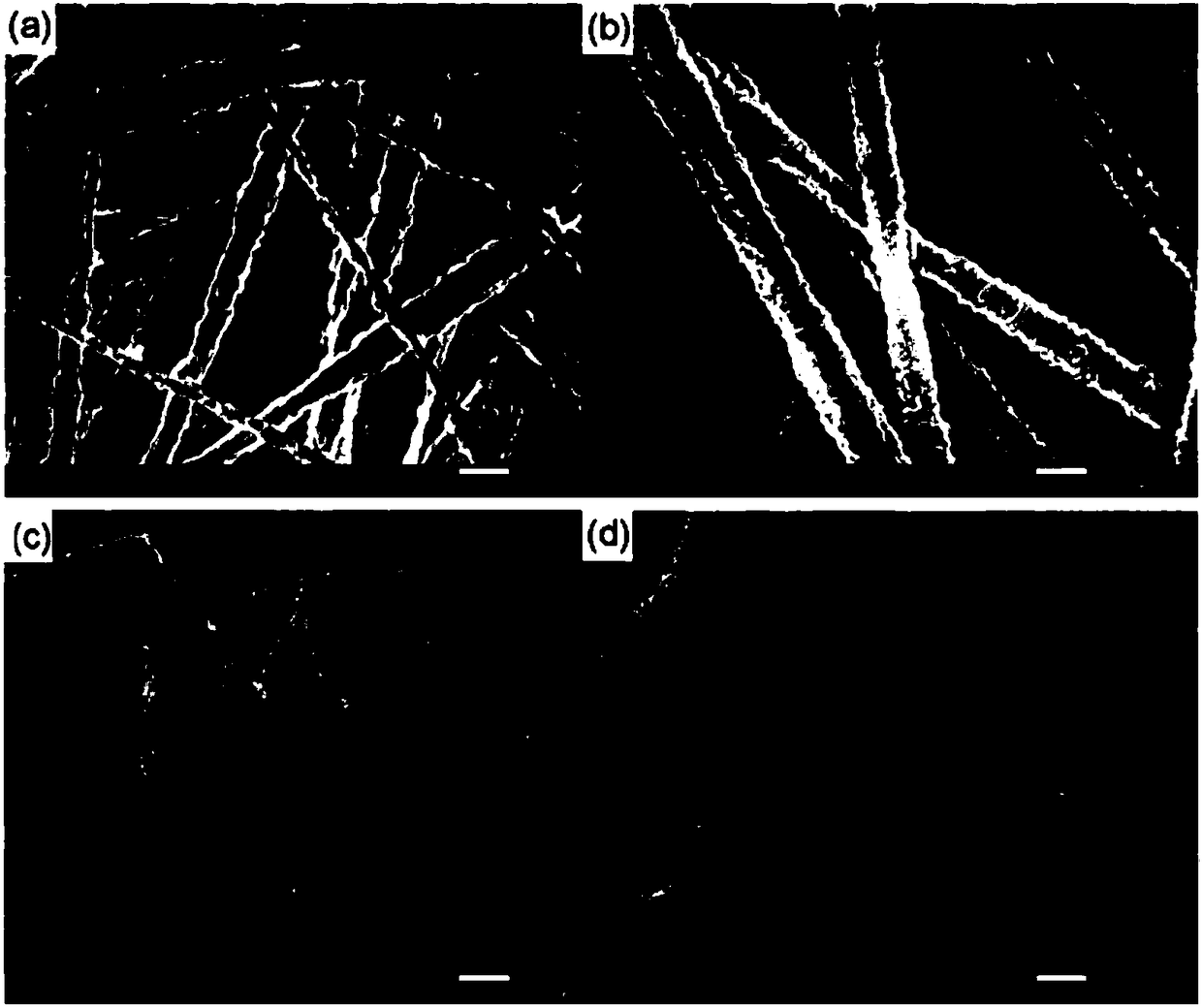

[0027] A PTFE material with a three-dimensional penetrating pore structure. There are stem holes on the stems surrounding the pores. The pore diameter is 100-1000nm; the stem diameter is 50-600nm, and the stem pore diameter is 30-200nm; the porosity of the pores is 50%- 90%, the porosity of the stem hole is 15-65%; the total surface area of the stem, stem area:stem hole area=1-30:1.

[0028] Stem surface area image analysis: photographs of the material were taken with a scanning electron microscope (SEM photographs, magnified 10000-50000 times). Scan this photo with image processing equipment (the television image processor TVIP-4100II that Japan Avionics company produces, the television image processor that Latock system engineering company provides) stem and stem hole are separated to obtain stem and stem hole image, The image is processed by software to obtain the respective areas, and the ratio of the stem area to the total image area of the stem hole area can be calcu...

Embodiment 2

[0040] The PTFE material of this embodiment has a three-dimensional penetrating pore structure. There are stem holes on the stems surrounding the pores. The pore diameter is 200±100 nm, the stem diameter is 125±75 nm, and the stem hole diameter is 50±20 nm.

[0041] The preparation method of described PTFE material, comprises the following steps:

[0042] (1) Preparation of spinning solution: dissolve polyvinyl alcohol in water to obtain a uniform solution with a concentration of 14-15%, add polytetrafluoroethylene (PTFE) emulsion (55-60%), so that the mass ratio of PTFE to polyvinyl alcohol is 2 -3:1; the preparation of the emulsion is to prepare high molecular polymer particles by emulsion polymerization, and the average particle diameter of the high molecular polymer particles is 15-40nm;

[0043] (2) Spinning: use high-voltage electrospinning equipment for electrospinning to obtain a uniform nanofiber precursor film; spinning voltage 15~20kV, distance 12~30cm;

[0044] (3...

Embodiment 3

[0051] The PTFE material of this embodiment has a three-dimensional penetrating pore structure, and there are stem holes on the stems surrounding the pores, 300nm

[0052] Wherein (I) the porosity of the pores is 60±10%, the porosity of the stem pores is 55±10%; the total surface area of the stems, stem area:stem hole area=1-15:1.

[0053] Or (II) the porosity of the pores is 60±10%, and the porosity of the stem pores is 55±10%; the total surface area of the stem, stem area:stem hole area=16-30:1.

[0054] Or (Ⅲ) the porosity of the pores is 80±10%, and the porosity of the stem pores is 30±15%; the total surface area of the stem, stem area:stem hole area=1-15:1.

[0055] Or (IV) The porosity of the pores is 80±10%, and the porosity of the stem pores is 30±15%; the total surface area of the stem, stem area:stem hole area=16-30:1.

[0056] The preparation method of described PTFE material, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com