Asphalt-based crack pouring adhesive and preparation method thereof

A joint-filling glue and asphalt-based technology, which is applied in the field of joint-filling glue, can solve the problems of poor low-temperature performance of asphalt joint-filling glue, and achieve the effects of reducing flow performance, improving low-temperature resistance, and not easy to absorb water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

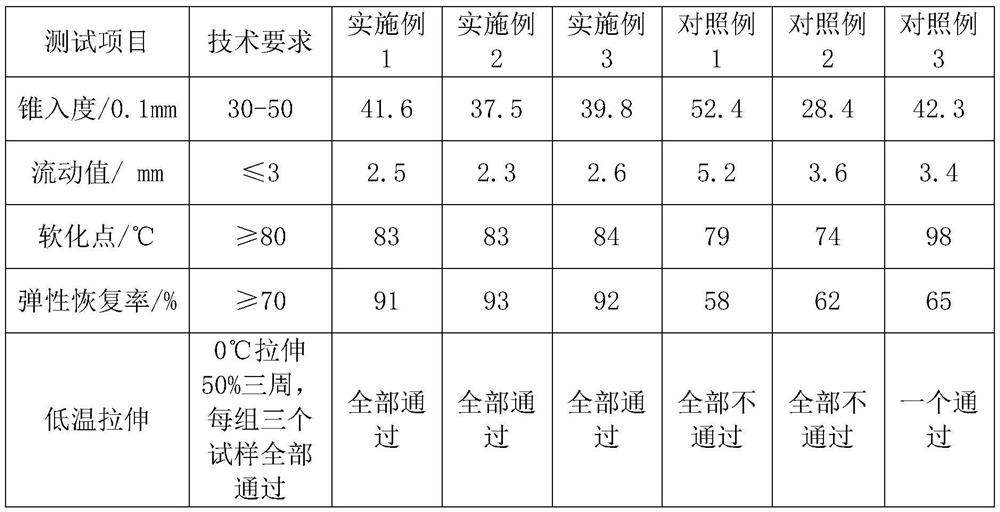

Examples

Embodiment 1

[0018] Dissolve 20kg of gelatin in 30kg of an aqueous solution containing 30wt% propylene glycol, then add 6kg of alkyd resin and heat to 85°C, then add 0.7kg of catalyst dibutyltin dilaurate, react for 3 hours, filter, and dry to obtain modified gelatin.

[0019] Then, heat 80kg of No. 70 petroleum asphalt to 180°C in a high-speed shearing machine, then add 4kg of modified gelatin and 8kg of rubber powder and cut for 35min, then add 1kg of 1,2,3,4-butanetetraol and 2kg of terephthalate Continue to shear the mixture of bishydroxyethyl formate for 10 minutes, cool down to room temperature, and keep it sealed to obtain asphalt-based joint glue.

Embodiment 2

[0021] Dissolve 24kg of gelatin in 30kg of an aqueous solution containing 32wt% propylene glycol, then add 5kg of alkyd resin and heat to 90°C, then add 0.5kg of catalyst dibutyltin dilaurate, react for 2.5 hours, filter, and dry to obtain modified gelatin.

[0022] Then, heat 100kg of No. 90 petroleum asphalt to 190°C in a high-speed shearing machine, then add 5kg of modified gelatin and 10kg of rubber powder and cut for 30min, then add 1kg of 1,2,3,4-butanetrol and 1.8kg of para The mixture of bishydroxyethyl phthalate continued to be sheared for 10 minutes, cooled down to room temperature, sealed and stored to obtain asphalt-based joint glue.

Embodiment 3

[0024] Dissolve 26kg of gelatin in 30kg of an aqueous solution containing 35wt% propylene glycol, then add 5kg of alkyd resin and heat to 80°C, then add 0.6kg of catalyst dibutyltin dilaurate, react for 3 hours, filter, and dry to obtain modified gelatin.

[0025] Then, heat 90kg of No. 80 petroleum asphalt to 190°C in a high-speed shearing machine, then add 3kg of modified gelatin and 10kg of rubber powder and cut for 30min, then add 1kg of 1,2,3,4-butanetetraol and 2kg of terephthalate Continue to shear the mixture of bishydroxyethyl formate for 10 minutes, cool down to room temperature, and keep it sealed to obtain asphalt-based joint glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com