Solvent-free two-component polyurethane adhesive for structural bonding and application thereof

A technology of polyurethane adhesive and two-component polyurethane, applied in the direction of polyurea/polyurethane adhesive, adhesive, non-polymer adhesive additive, etc., can solve the problems of low elongation at break, harmful to human health, unfavorable to environmental protection, etc. , to achieve the effect of excellent aging resistance, good bonding effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

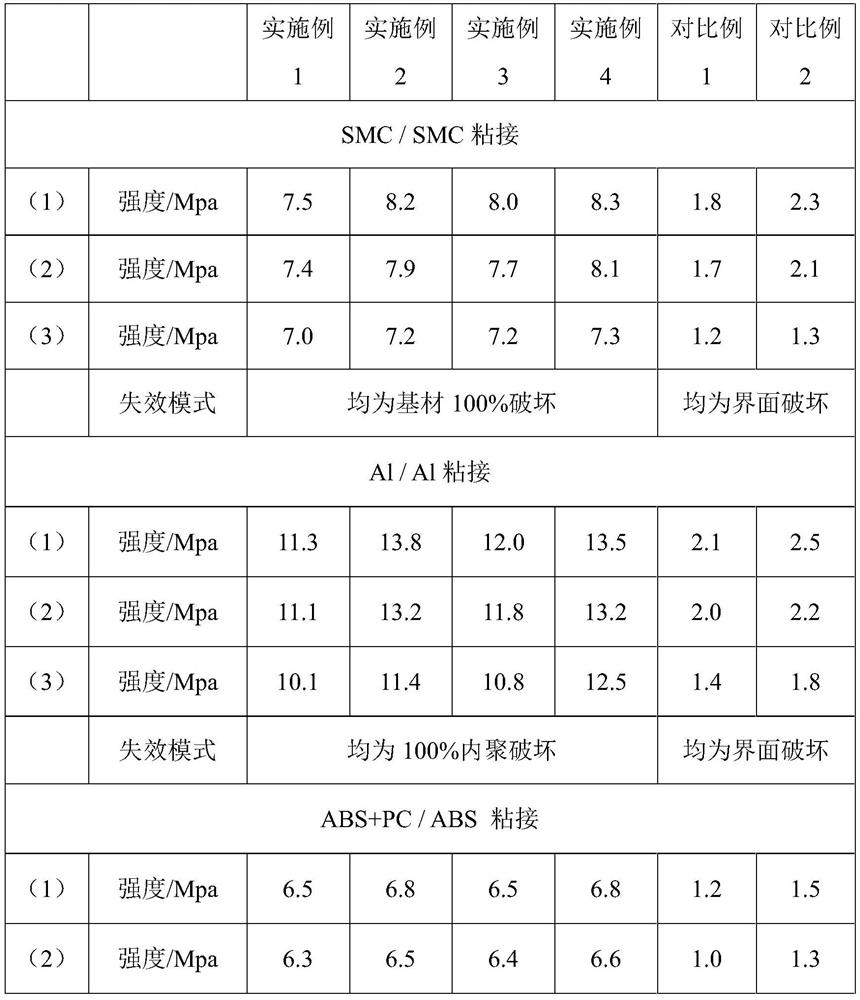

Examples

Embodiment 1

[0036] This example provides a solvent-free two-component polyurethane adhesive for structural bonding, which consists of component A and component B;

[0037] Component A contains the following components in parts by weight: 40 parts of BASF Sovermol 805, 10 parts of EG, 46 parts of calcium carbonate, 2 parts of 3A molecular sieve, 1 part of fumed silica, 0.5 part of carbon black, 0.5 part of dibutyltin dilaurate share;

[0038] Component B comprises the following components in parts by weight: 40 parts of isocyanate-terminated polyurethane prepolymer (NCO%=20%), 10 parts of HDI, 46 parts of calcium carbonate, 2 parts of 3A molecular sieve, 1 part of fumed silica, 1 copy of KH560;

[0039] The isocyanate-terminated polyurethane prepolymer is prepared by reacting polyester polyol (Shanghai Lianjing POL-8520) with isocyanate (MDI-50).

Embodiment 2

[0041] This example provides a solvent-free two-component polyurethane adhesive for structural bonding, which consists of component A and component B;

[0042] Component A contains the following components in parts by weight: 20 parts of Shanghai Jingri AP11, 4 parts of glycerin, 20 parts of silicon micropowder, 0.5 part of 3A molecular sieve, 0.5 part of organic bentonite, 0.1 part of iron black, and 0.5 part of dibutyltin dilaurate ;

[0043] Component B comprises the following components in parts by weight: 20 parts of isocyanate-terminated polyurethane prepolymer (NCO%=15%), 15 parts of cyclohexane dimethylene diisocyanate, 20 parts of aluminum hydroxide, 0.5 parts of 4A molecular sieve Part, 0.5 part of fumed silica, 0.5 part of β-(3,4-epoxycyclohexyl) ethyltrimethoxysilane;

[0044]The isocyanate-terminated polyurethane prepolymer is prepared by reacting polyester polyol (Shanghai Lianjing POL-8520) with isocyanate (MDI-50).

Embodiment 3

[0046] This example provides a solvent-free two-component polyurethane adhesive for structural bonding, which consists of component A and component B;

[0047] Component A comprises the following components in parts by weight: 60 parts of BASF Sovermol 805, 15 parts of trimethylolpropane, 50 parts of alumina, 8 parts of 3A molecular sieves, 8 parts of fumed silica, 2 parts of carbon black, dilaurel 1 part of dibutyltin acid;

[0048] Component B comprises the following components in parts by weight: 70 parts of isocyanate-terminated polyurethane prepolymer (NCO%=10%), 30 parts of toluene diisocyanate, 50 parts of aluminum oxide, 8 parts of 3A molecular sieve, and 8 parts of fumed silica Parts, 2 parts of γ-aminopropyltrimethoxysilane;

[0049] Isocyanate-terminated polyurethane prepolymers were prepared by reacting polycaprolactone polyol (Pastor CAPA 2200) with isocyanate (MDI-50).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com