High-impact transparent permanent antistatic polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene modification, can solve the problems of limited improvement, easy yellowing, poor material transparency, etc., to maintain high impact performance, reduce refractive index differences, and improve impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

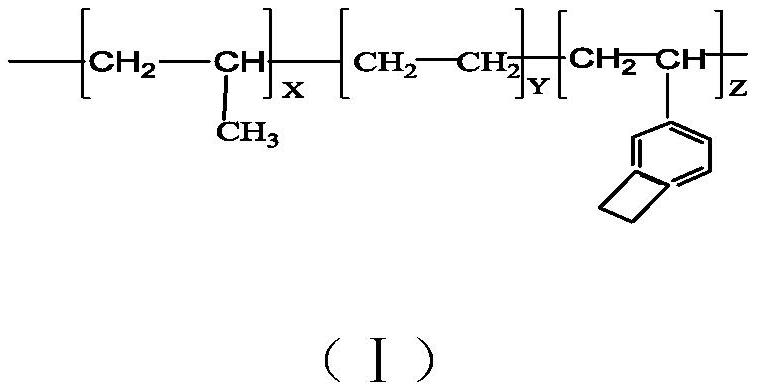

[0061] (1) Preparation of functionalized binary ethylene ethylene rubber:

[0062] The entire reaction was carried out in a 20L reaction kettle, and the reaction was baked before the reaction was baked, and the replacement of high purity nitrogen was used to remove the oxygen, monomeric ethylene, propylene, and 4-vinylbenzene in the reactive kettle with high purity nitrogen. The mass ratio is 45: 54: 1, and the propylene and ethylene gas to be reacted are introduced into the reactor, and then n-hexane, 4-vinylbenzene cyclobutylene is sequentially added to the reactor, and then the main catalyst Et (Ind) is added. 2 Zrcl 2 The propylene monomer is 1: 30000, stirring activates 2 min, and then adding the cocatalyst MAO, control the addition of the Al / Zr molar ratio of 2000: 1, the polymerization temperature is 35 ° C, the reaction time is 25 min, and the access is transferred Hydrogen adjustment weight average molecular weight is about 200,000, and the reaction is added to the end ...

Embodiment 2

[0070] (1) Preparation of functionalized binary ethylene ethylene rubber:

[0071] The entire reaction was carried out in a 20L reaction kettle, and the reaction was baked before the reaction was baked, and the replacement of high purity nitrogen was used to remove the oxygen, monomeric ethylene, propylene, and 4-vinylbenzene in the reactive kettle with high purity nitrogen. The mass ratio is 52: 46: 2, first passing into the propylene and ethylene gas to be reacted, n-hexane, 4-vinylbenzene and cyclobutylene is sequentially added to the reaction kettle, then the main catalyst Et (Ind) is added. 2 Zrcl 2 The propylene monomer is 1: 30000, stirring activates 2 min, and then adding the cocatalyst MAO, control the addition of the Al / Zr molar ratio of 2000: 1, the polymerization temperature is 35 ° C, the reaction time is 25 min, and the access is transferred Hydrogen adjustment weight average molecular weight is about 200,000, and the reaction is added to the end of the reaction, a...

Embodiment 3

[0076] (1) Preparation of functionalized binary ethylene ethylene rubber:

[0077] The entire reaction was carried out in a 20L reaction kettle, and the reaction was baked before the reaction was baked, and the replacement of high purity nitrogen was used to remove the oxygen, monomeric ethylene, propylene, and 4-vinylbenzene in the reactive kettle with high purity nitrogen. The mass ratio is 48: 49: 3, first passing into the propylene and ethylene gas to be reacted, n-hexane, 4-vinylbenzene cyclobutylene is added to the reactor, then the main catalyst Et (Ind) is added. 2 Zrcl 2 The propylene monomer is 1: 30000, stirring activates 2 min, and then adding the cocatalyst MAO, control the addition of the Al / Zr molar ratio of 2000: 1, the polymerization temperature is 35 ° C, the reaction time is 25 min, and the access is transferred Hydrogen adjustment weight average molecular weight is about 200,000, and the reaction is added to the end of the reaction, and the polymerization liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com