Molecular-level production process and device of inulin

A production process and production device technology, which is applied in the field of molecular-level production process and device of inulin, can solve the problems of single variety and functional inability to meet market demand, and achieve good effect, low production cost and reduced steam consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

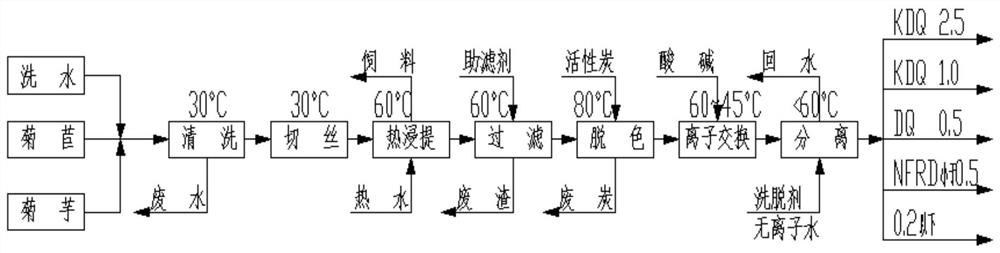

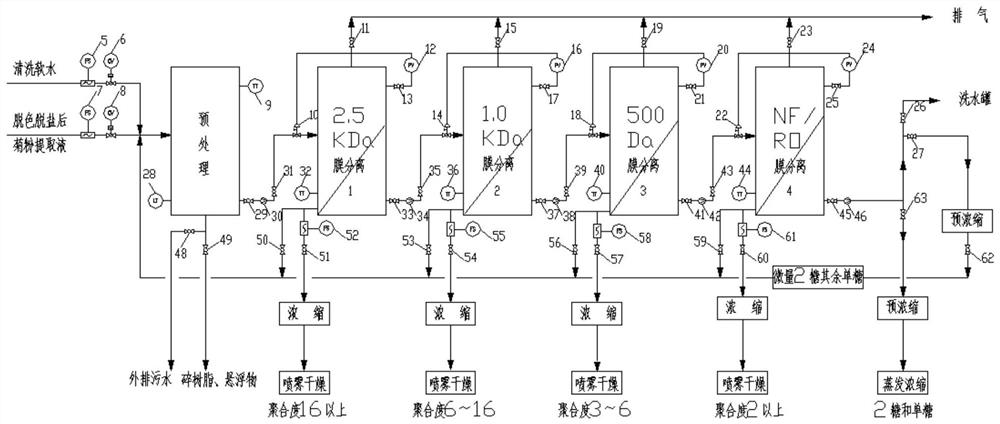

[0078] Wash the chicory (Jerusalem artichoke) and shred it, then heat the water for leaching according to the solid-to-liquid ratio of 1:1.5, the leaching temperature is controlled at 60°C, and the leaching time is 45min; % of diatomite filter aid, using a ceramic microfiltration membrane with an average pore size of 200nm to filter and remove impurities. The membrane surface flow rate during the filtration process is 3m / s. , the amount of activated carbon is 1wt% of the weight of the feed liquid, and the decolorization temperature is 75°C. After filtering the activated carbon, the feed liquid is cooled to room temperature and sent to weakly basic anion exchange resin D301 to extract inulin, and then use deionized water For elution, the eluate is first filtered and concentrated with an ultrafiltration membrane with a molecular weight cut-off of 2500, and the concentrated solution is spray-dried to obtain the first-grade inulin. Drying to obtain the second-stage inulin, the per...

Embodiment 2

[0080] Wash the chicory and cut it into shreds, add water for extraction according to the solid-to-liquid ratio of 1:2, control the extraction temperature at 55°C, and extract for 40 minutes; after the initial removal of solid residues in the extraction solution, add about 2wt% of silicon The algal earth filter aid uses a ceramic microfiltration membrane with an average pore size of 50nm to filter and remove impurities. The membrane surface flow rate during the filtration process is 2m / s. After the filtrate is collected, it is added to the decolorization kettle for decolorization treatment. The weight of the feed liquid is 3wt%, the decolorization temperature is 80°C, and after the activated carbon is filtered out, the feed liquid is cooled to room temperature and sent to the strong acidic cation exchange resin D001-F to extract inulin, and then eluted with deionized water. The eluate is firstly filtered and concentrated with an ultrafiltration membrane with a molecular weight ...

Embodiment 3

[0082] Wash the chicory and shred it, add water according to the solid-to-liquid ratio of 1:1.2 for leaching, control the leaching temperature at 50°C, and leaching time for 60 minutes; after the leaching solution initially removes solid residues, add about 2wt% silicon Algae earth filter aid, using a ceramic microfiltration membrane with an average pore size of 200nm to filter and remove impurities. The membrane surface flow rate during the filtration process is 4m / s. After the filtrate is collected, it is added to the decolorization kettle for decolorization treatment. The weight of the feed liquid is 2wt%, the decolorization temperature is 75°C, and after the activated carbon is filtered out, the feed liquid is cooled to room temperature and sent to the strong basic anion exchange resin D201 to extract the inulin, and then eluted with deionized water. The solution is firstly filtered and concentrated with an ultrafiltration membrane with a molecular weight cut-off of 2500, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com