Driving unit and multi-mode driving vehicle for mining low distributed support carrier

A drive unit, distributed technology, applied in power units, vehicle components, electric power units, etc., can solve problems such as the inability to effectively solve the problem of thin coal seam and low roadway traffic, difficult vehicle height control, and difficulty in troubleshooting and maintenance. Achieve the effect of solving the driver's vision blocking, improving the vehicle control effect, and realizing the loading demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

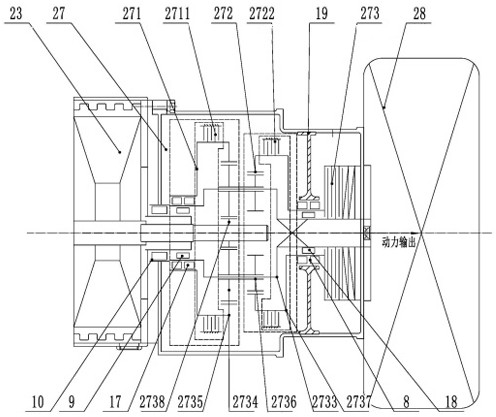

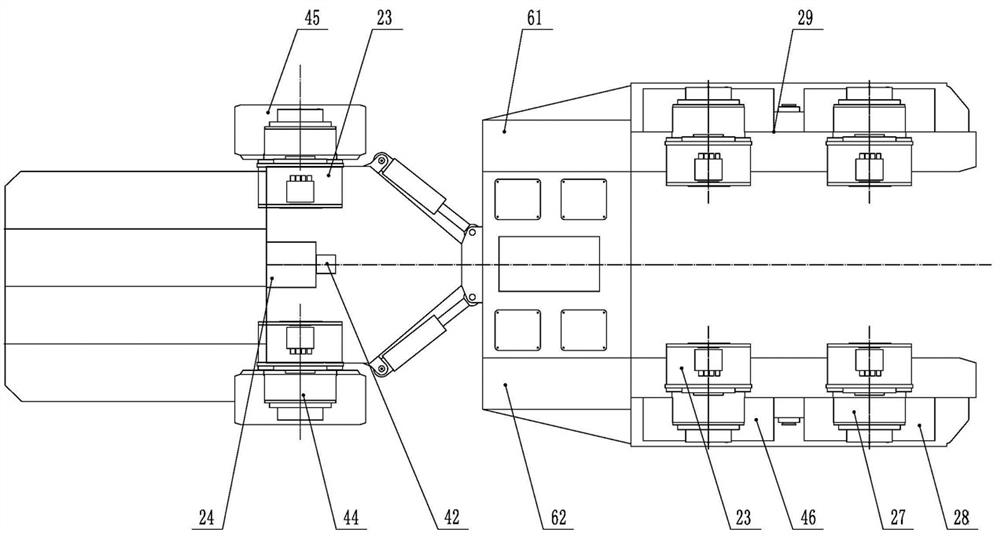

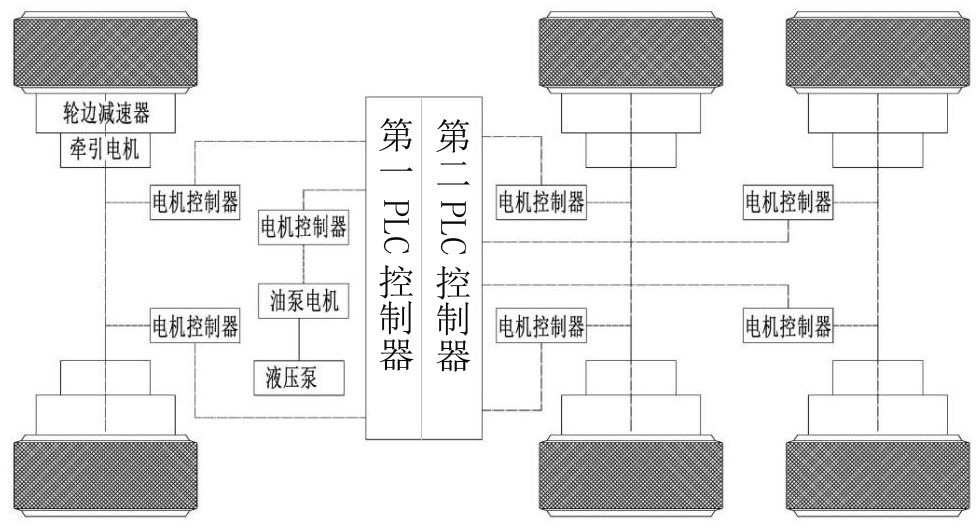

[0022] Such as figure 1 As shown, a driving unit for a mine-used low-profile distributed support truck includes a traction motor 23, a wheel-side reducer 27 and wheels 28, and the wheel-side reducer 27 includes a primary reduction mechanism 271 and a secondary reduction mechanism. Mechanism 272 and wet brake 273, the primary reduction mechanism 271 is a NGW type planetary reducer, the secondary reduction mechanism 272 is an NW type planetary reducer, the output shaft of the traction motor rotor passes through the primary reduction mechanism 271, the secondary reduction mechanism 272 and the wet brake 273 are connected with the wheel 28 shafts to form transmission cooperation. The primary reduction mechanism is provided with a first gear clutch 2711, and the secondary reduction mechanism 272 is provided with a second gear clutch 2722. According to the classification of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com