Grooving device for milling cutter production

A milling cutter and material placement technology, which is applied in the direction of grinding drive devices, grinding workpiece supports, grinding machines, etc., can solve the problems of low processing efficiency, achieve the effects of improving processing efficiency, enhancing stability, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

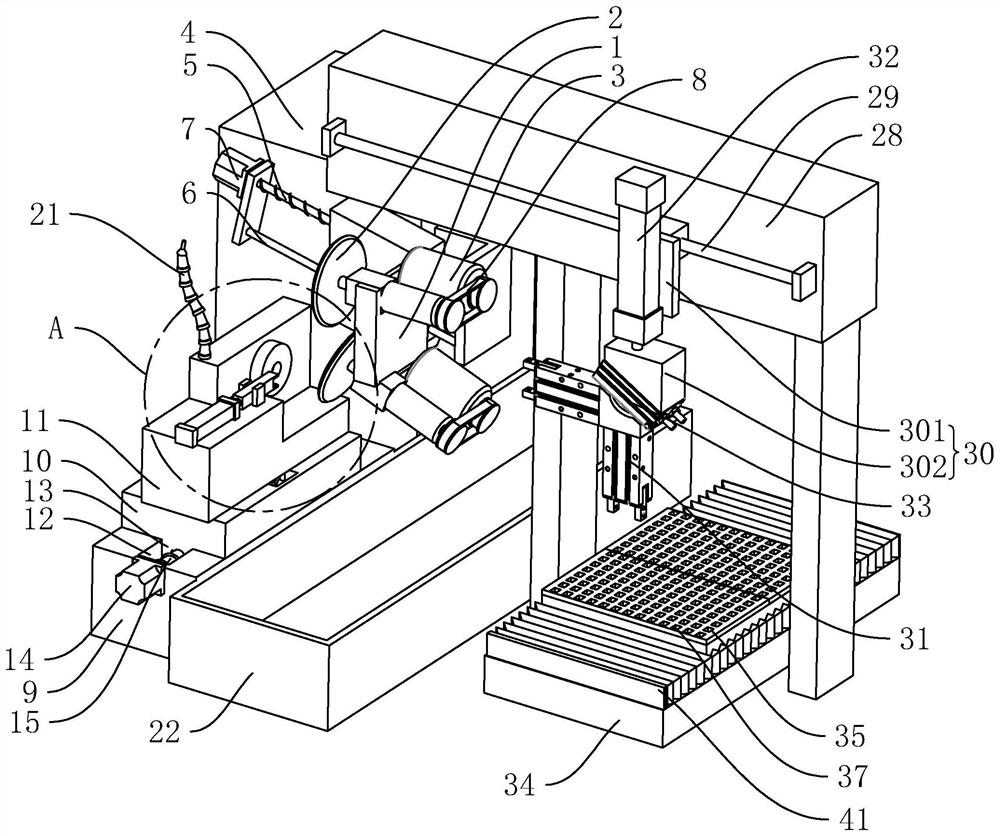

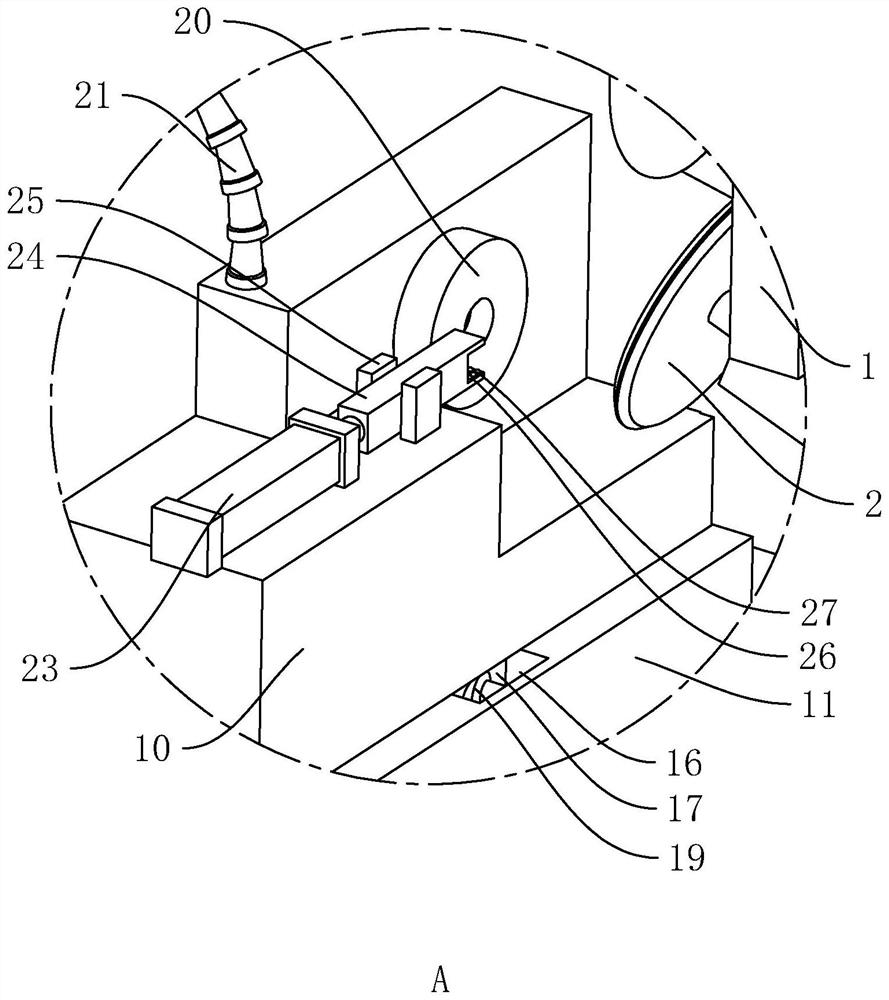

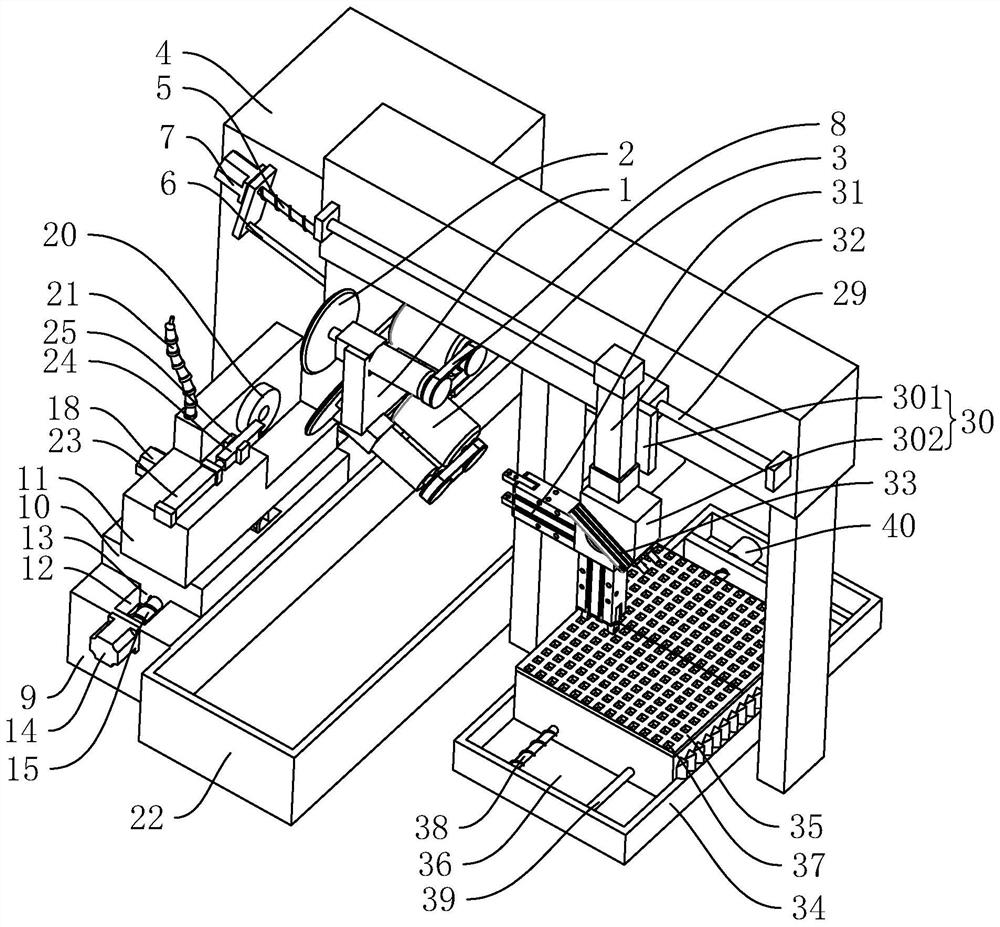

[0039] The following is attached Figure 1-3 The application is described in further detail.

[0040] The embodiment of the present application discloses a slotting device for milling cutter production. refer to figure 1 , The slotting device for milling cutter production includes a cutting mechanism, a fixing mechanism, a clamping and conveying mechanism, and a material placement mechanism, wherein the cutting mechanism is used for cutting and processing the workpiece, and the fixing mechanism is used for fixing the workpiece during processing, clamping and conveying The mechanism is used to transport the workpieces to be processed and processed, and the material placement mechanism is used to place the workpieces to be processed and processed.

[0041] Continue to refer to figure 1 , the cutting mechanism includes a cutting frame 1, two cutting wheels 2, two driving motors 3 and a cutting slide assembly, the cutting slide assembly includes a fixed frame 4, a cutting slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com