A high-speed friction stir adjustment method and welding tool with adjustable axial force of the stirring pin

A technology of friction stir and needle stirring, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., and can solve problems such as unsuitable for high-speed friction stir welding, unsuitable for high-speed stir-grinding welding, and large volume of the withdrawal device , to achieve the effect of overcoming the problem of installation accuracy, good tolerance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better describe the technical solution of the present invention, the present application will be further described below in conjunction with the accompanying drawings.

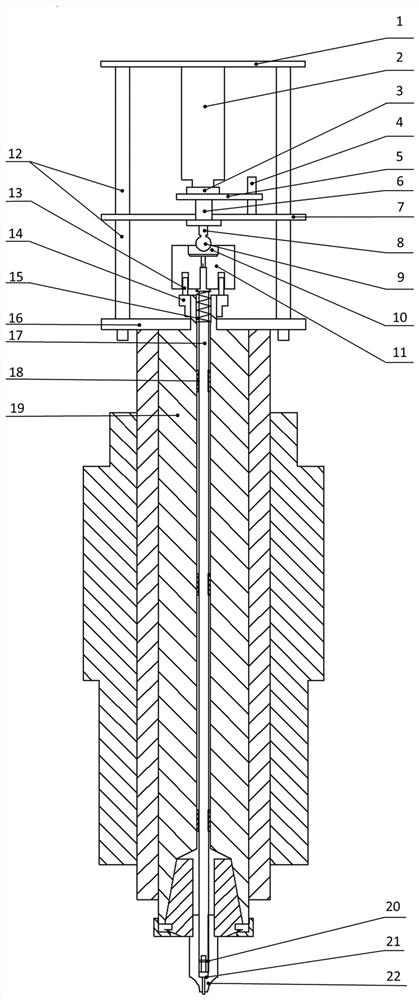

[0034] A high-speed friction stirring adjustment method with adjustable axial force of a stirring needle and a welding tool, including a stepping motor 2, the bottom of the stepping motor 2 is fixed on the top fixing device 1, and a pressure sensor is installed on the output shaft of the stepping motor 2 3. It is perpendicular to the horizontal plane and connects with the connecting plate 5. The first connecting rod 8 is fixed on the lower surface of the connecting plate 5. The other end of the first connecting rod 8 is fixed with a pressure ball 9. The linear bearing 6 is fixed on the middle fixing device. 7, the middle fixing device 7 is provided with a first threaded hole 73 for fixing with the linear bearing 5, and the first connecting rod 8 is matched with the linear bearing 5; the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com