Integrated filling machine with outer encircling mechanism

A filling machine and integrated technology, applied in packaging, transportation and packaging, liquid distribution, conveying or transfer devices, etc., can solve problems such as large volume, inability to meet individual needs, lack of rigid protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

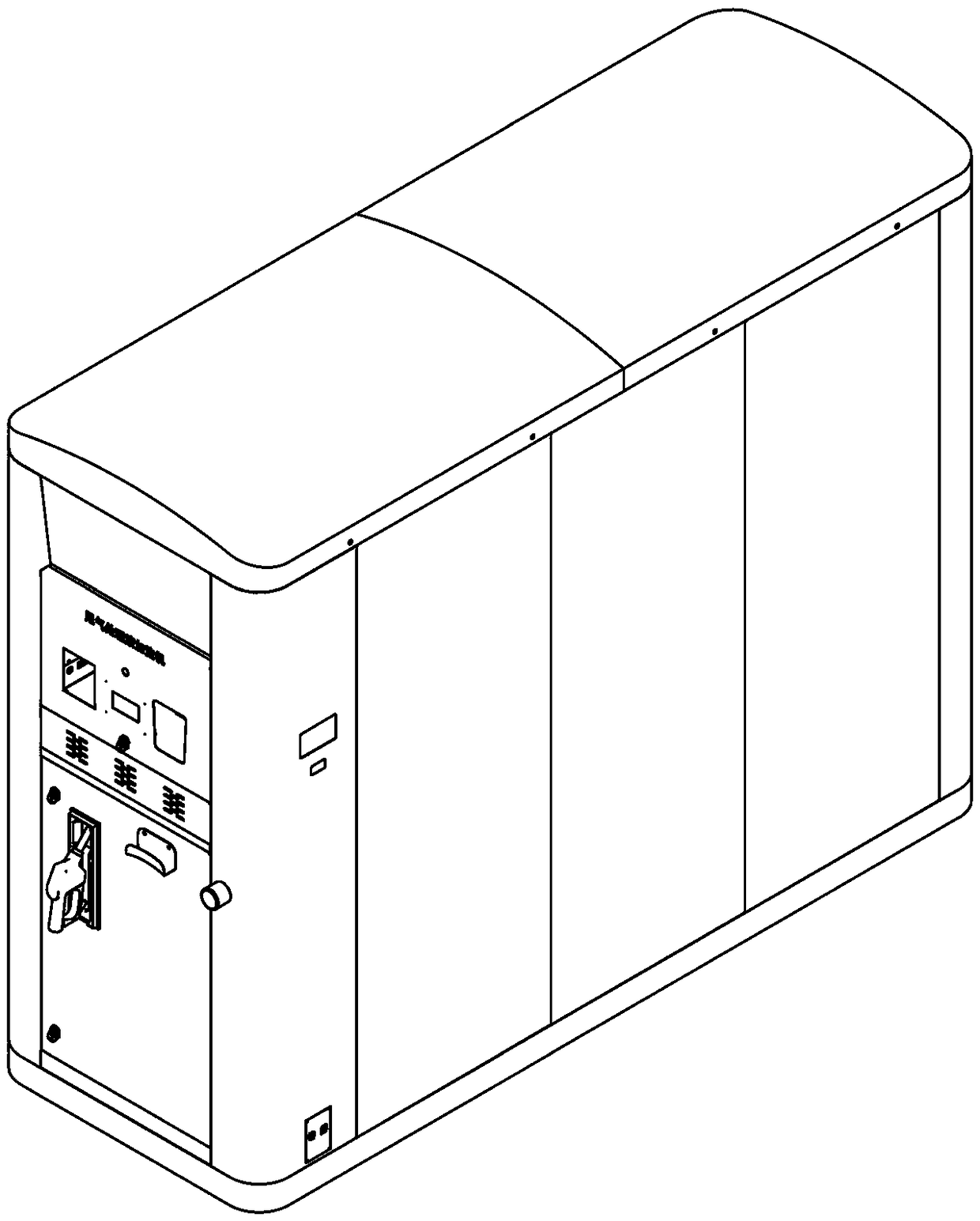

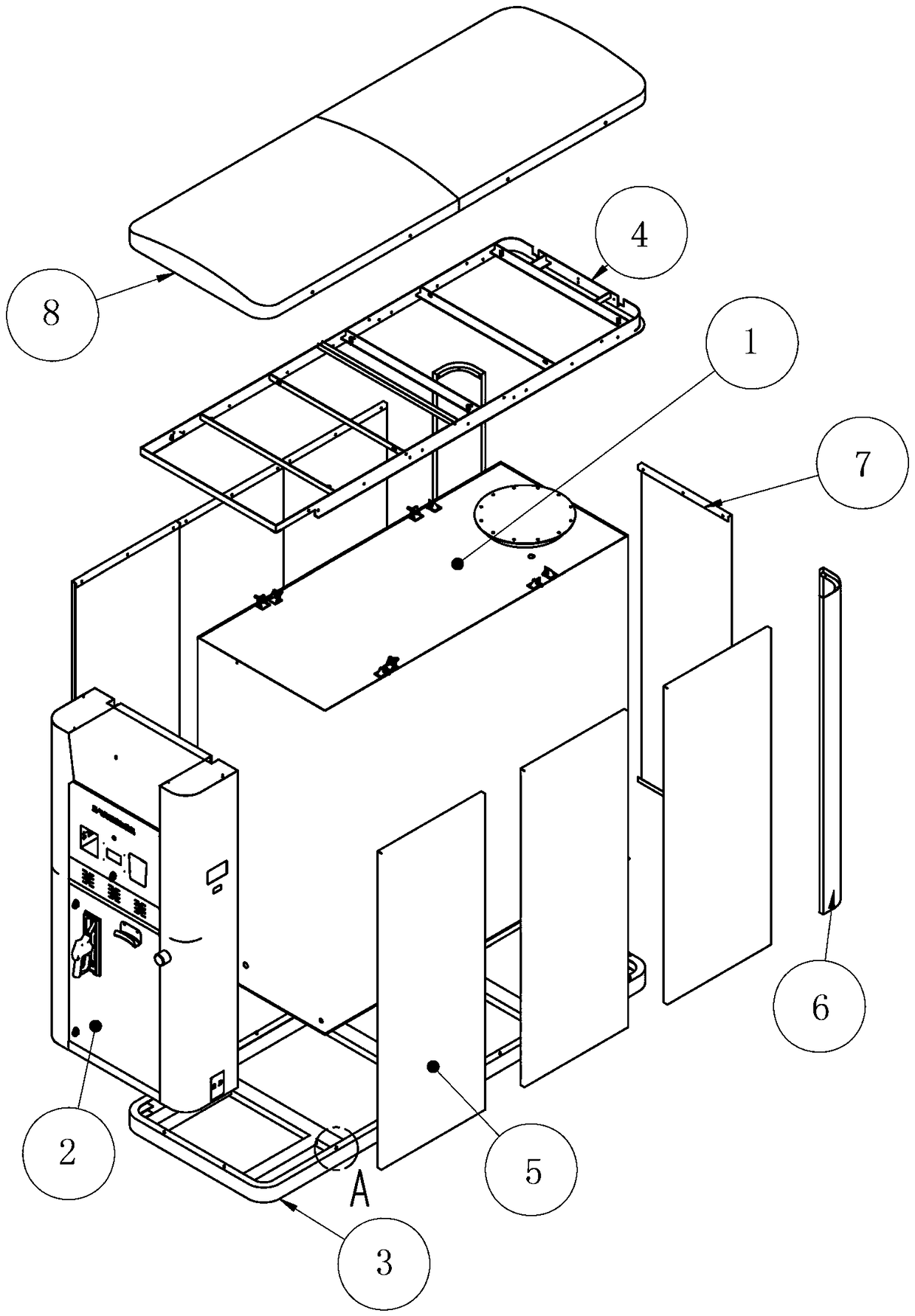

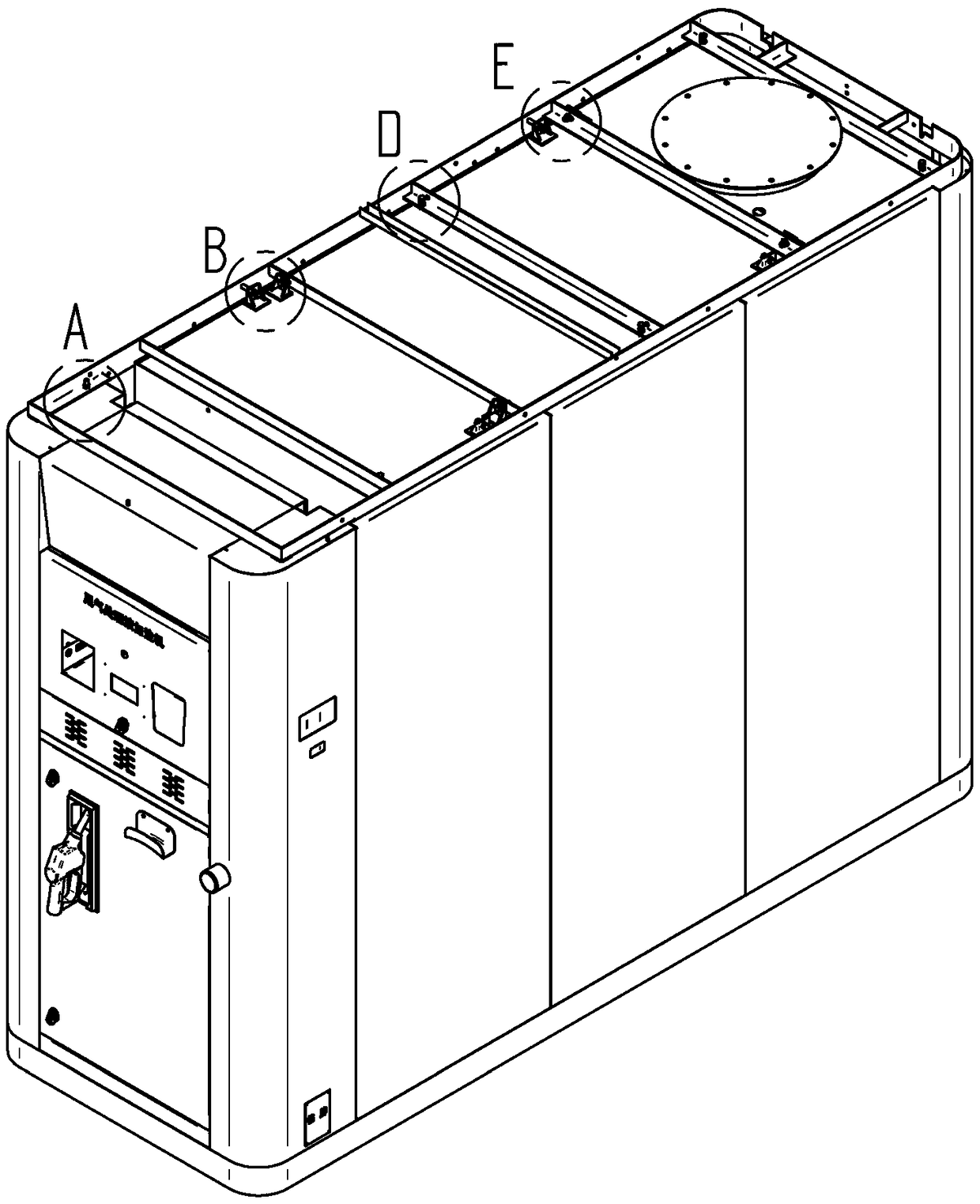

[0029] like Figure 1-8 As shown, an integrated filling machine with an outer enclosure mechanism, including a liquid storage tank 1 and a matching filling machine 2, and further includes a base frame 3, a top fixed frame 4 and several outer enclosure panels , the liquid storage tank 1 and the filling machine 2 are fixed on the base frame 3, and the top fixed frame 4 is fixed on the top of the liquid storage tank 1 and the filling machine 2; the liquid storage tank 1 and the filling machine 2 are covered with several outer Surrounding boards, each outer surrounding board is installed through the base frame 3 and / or the top fixing frame 4 .

[0030] The outer enclosure panel of this embodiment is composed of side enclosure panel 5, corner enclosure panel 6, back enclosure panel 7 and top enclosure panel 8, side enclosure panel 5 is spliced by several sub-panels, side enclosure panel 5, corner enclosure panel 6. The back surrounding panels 7 are spliced together to form the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com