Flow field calibration device

A flow field and calibration technology, which is applied in the field of flow field calibration and measurement devices of high-altitude simulated test benches, can solve problems such as the difficulty in solving the fixed structure of the swing end of the measurement device, achieve reliable measurement results, satisfy synchronization, and facilitate repeated disassembly The effect of pretending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

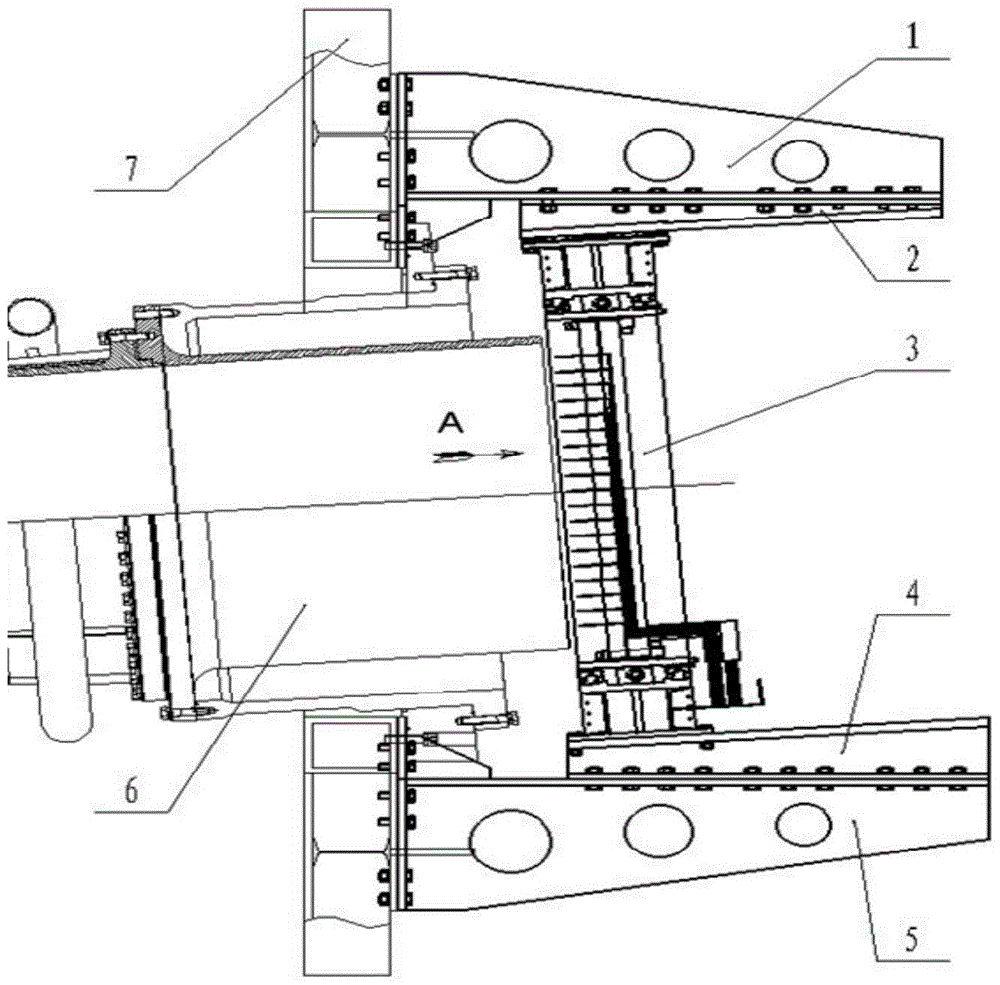

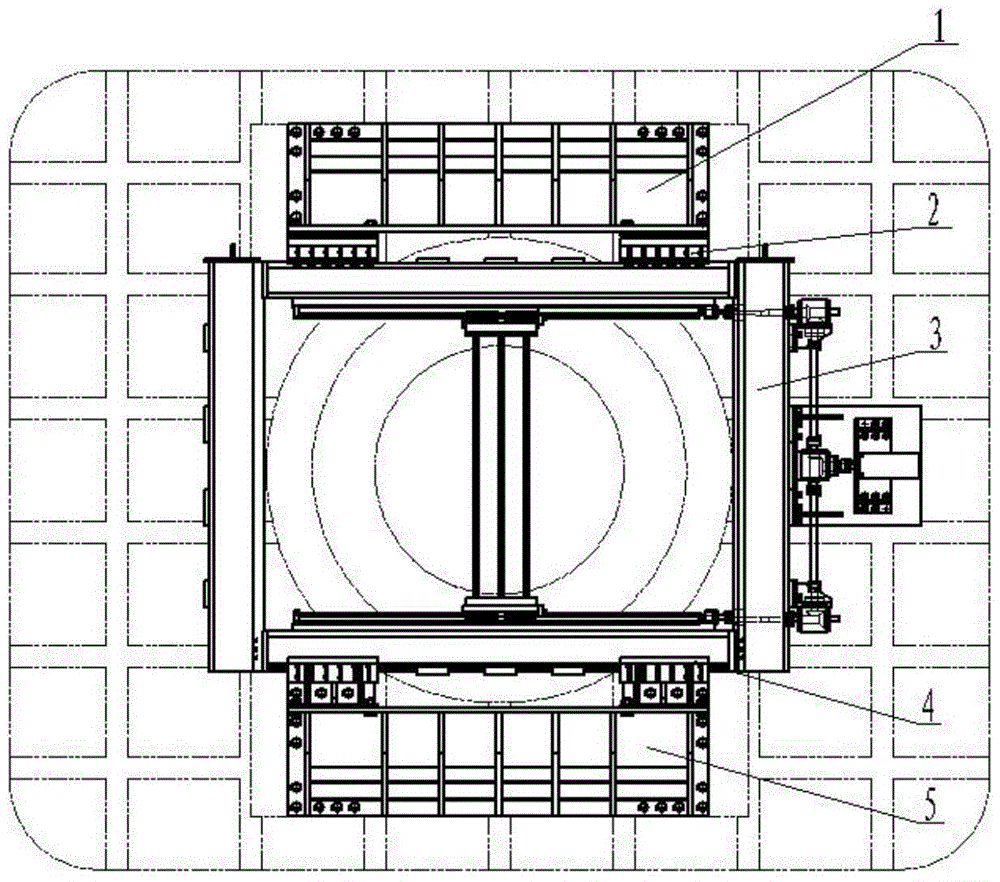

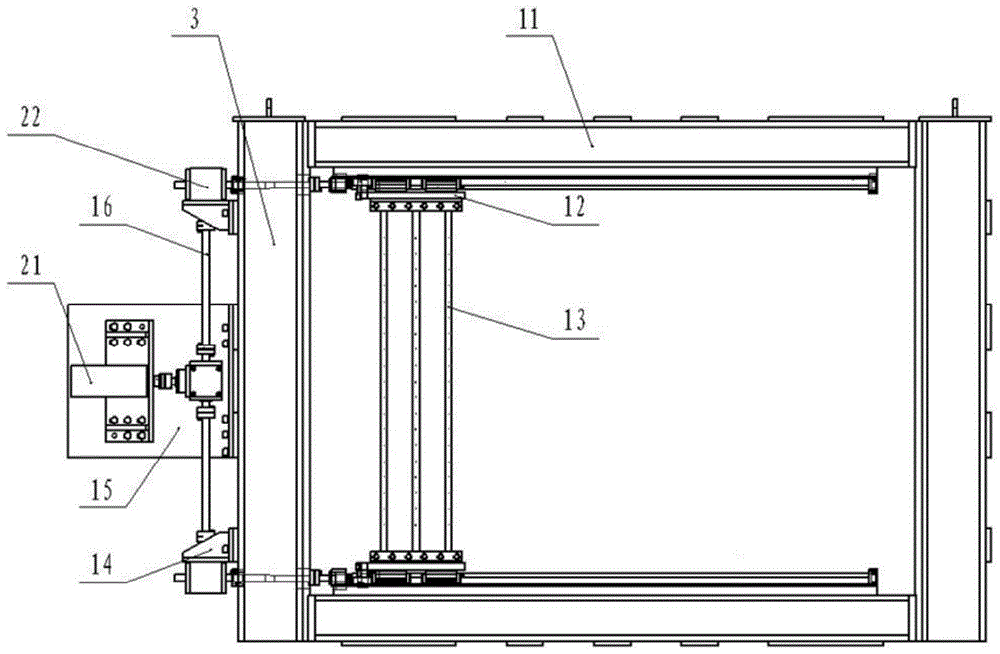

[0028] Such as figure 1 , figure 2 with image 3 As shown, the flow field calibration device for the test bench includes an upper bracket 1 , an upper inclined support 2 , a measuring mechanism 3 , a lower inclined support 4 , and a lower bracket 5 . The measuring mechanism 3 includes a measuring frame 11 , an adapter 12 , a measuring rake group 13 , a commutator bracket 14 , a motor bracket 15 and a drive system 16 .

[0029] The upper bracket 1 is L-shaped and has two mutually perpendicular planes, one plane is fixed on the test chamber 7 directly above the nozzle 6 by bolts, and the other side is used as the installation plane of the upward inclined support 2 and protrudes in front of the nozzle 6 in the flow field directly above . The upper inclined support 2 is a bracket with a 4-degree inclined surface. The degree of the inclined surface can be changed according to the degree of elevation angle of the nozzle 6. The opposite side of the inclined surface is a plane. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com