Metal ceramic composite riser tube and preparation method thereof

A metal-ceramic composite and riser technology, applied in the direction of inorganic adhesives, adhesives, etc., to achieve the effects of easy and rapid preparation, reduced use costs, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

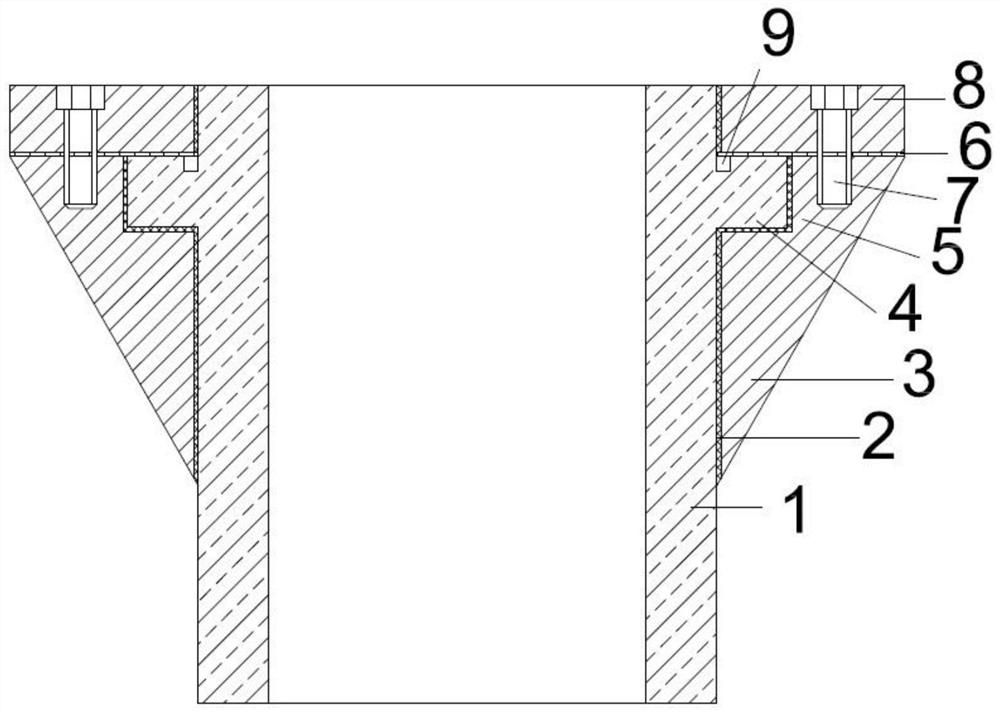

[0033]Such asfigure 1 As shown, the metal ceramic composite lifting tube of the present invention includes a ceramic lifting tube 1 and a ring sleeve in the outer surface of the ceramic lifting tube 1, the outer surface of the ceramic lifting tube 1 and the inner surface of the metal flange. There is a bonding layer 2 between the upper surface of the ceramic lifting tube 1, which includes a boss 4, which includes a metal flange 8 and a metal lower flange. 3, and the metal upper flange 8 and the metal lower flange 3 are provided with an elastic feeding pad 6, and the upper end of the inner surface of the metal lower flange 3 is opened, and the groove 5 is connected to the boss 4. The upper surface of the boss 4 is open to the outer surface joint of the ceramic lifting tube 1 with a reverse airflow passage 9.

[0034]The metal ceramic composite lifting tube of the present invention includes a ceramic lifting tube 1 and a metal flange outside the ceramic lifting tube 1, first passing betw...

Embodiment 2

[0043]The preparation method of the metal ceramic composite rising liquid pipe includes the following steps:

[0044]Step 1, the ceramic lifting tube 1, the metal upper flange 8 and the metal lower flange 3 are cleaned;

[0045]Step 2, apply the adhesive to the outer surface of the ceramic lifting tube 1 after the surface cleaner in the step, and the inner surface of the flange 8 and the metal lower flange 3 after the surface is cleaned; The preparation method of the latter is: the mass concentration of 85%, the distilled water is well mixed with aluminum hydroxide, and then stirred at 70 ° C for 3 h, then adding alumina and magnesium oxide to continue stirring for 2 h, mix well, cooled The mass content of 85% by mass concentration of 85% in the adhesive is 39%, and the mass content of distilled water is 38%, and the mass content of aluminum hydroxide is 14%, and the mass content of alumina is 6%. The mass content of magnesium oxide is 0.3%;

[0046]Step three, the ceramic lifting tube 1 of ...

Embodiment 3

[0049]The present embodiment differs from the first embodiment in the preparation method of the adhesive: the phosphoric acid solution of 85% by mass, the distilled water is well mixed with aluminum hydroxide, and then stirred at 80 ° C for 2 h, then add alumina And the magnesium oxide continued for 2 h, mixed uniform, cooled to obtain an adhesive, the mass concentration of 85% of the mass concentration of 85% was 37%, and the mass content of distilled water was 42%, and the mass content of aluminum hydroxide. It was 13.5%, and the quality of alumina was 7%, and the mass content of magnesium oxide was 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com