Oil mist filter

A technology for oil mist filtration and filtration mechanism, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc. The effect of electricity, saving resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

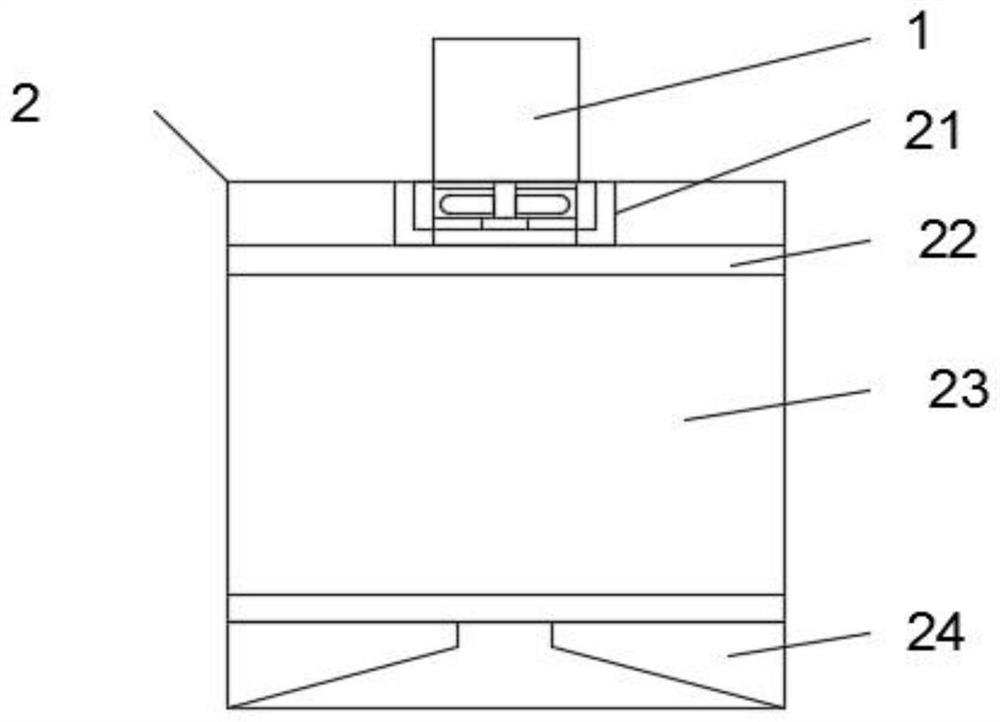

Image

Examples

Embodiment 1

[0044] On the outer surface of the separation mechanism 3, there is a large, small observation window, the exhaust fan 21, and the intake fan 62 are electrically connected to the external power supply, and the air mist mixed gas inhaled in the guide tube 61 is activated. The guide pipe 61 has a helical shape, and the drawing of the guide tube 61 has a spiral gas stream under the thrust of the suction fan 62, and the water droplets produced by the oil mist mixed gas will enter the air tube 61 through the intake pipe 183. The inside of the filter one 81, and the inside of the filter 1 81 is set to generate a collision, the contact surface is increased, and the filter is filtered through the filter body, the filter 1 and the filter 2 85 are the same, fixed seats The number is four, the position of the fixed seat one 9 and the connecting tube 12 corresponds, and the fixing seat is provided with a sink in communication with the connecting tube 12, the filter 181 and the fixed seat one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com