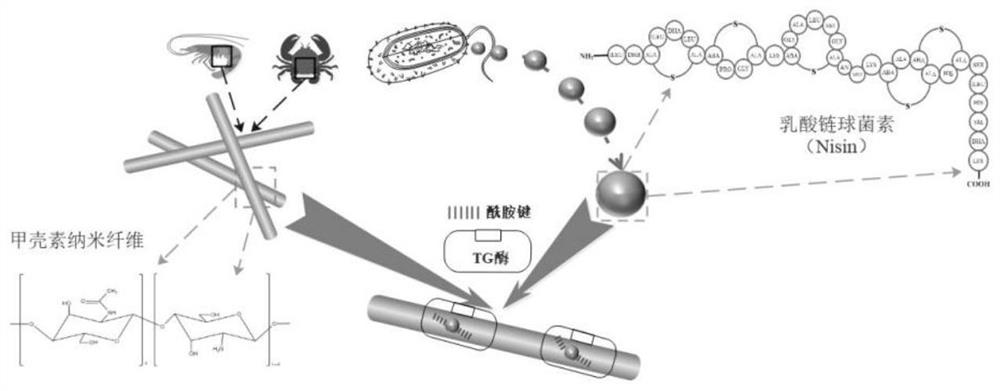

Chitin nanofiber/Nisin composite preservative based on transglutaminase induced crosslinking and preparation method

A technology of transglutaminase and nanofibers, which is applied in fiber processing, animal fiber, biochemical fiber processing, etc., can solve the problems of non-compliance with green safety and safety to be verified, and achieve stable structure, safe source of raw materials, and improved The effect of antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a chitin nanofiber / Nisin composite preservative based on transglutaminase-induced crosslinking and a preparation method thereof, comprising the following steps:

[0029] Preparation of S1 chitin nanofibers:

[0030] Disperse the chitin powder in 33% (w / v) sodium hydroxide and 0.3% sodium borohydride (w / v), in a water bath at 90°C, magnetically stir for 4 hours, and the obtained chitin solution is suction filtered , washing, the obtained residue was dried in an oven at 45° C. for 1 h, dissolved with 1% (v / v) acetic acid solution, ultrasonically treated for 1 h, left to stand for 30 min, and the supernatant was taken out and freeze-dried to obtain chitin nanofibers;

[0031] Preparation of S2 transglutaminase-induced cross-linked chitin nanofiber / Nisin composite preservative:

[0032] Put the chitin nanofibers described in S1 in 1% glacial acetic acid solution (v / v), and use ultrasonic treatment for 1 h to prepare a chitin nanofiber solution with a...

Embodiment 1

[0041] Preparation of S1 chitin nanofibers:

[0042] The chitin powder was dispersed in 33% (w / v) sodium hydroxide and 0.3% sodium borohydride (w / v), in a water bath at 90°C, and magnetically stirred for 4 hours. The solution was suctioned, filtered, and washed with deionized water until the filtrate was clear and colorless. The collected residue was dried in an oven at 45° C. for 1 h, dissolved with 1% (v / v) acetic acid solution, ultrasonically treated for 1 h, allowed to stand for 30 min, and the supernatant was taken out and freeze-dried for 24 h to obtain chitin nanofibers.

[0043] Preparation of S2 transglutaminase-induced cross-linked chitin nanofiber / Nisin composite preservative:

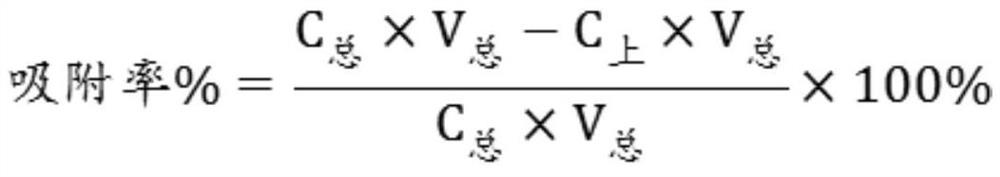

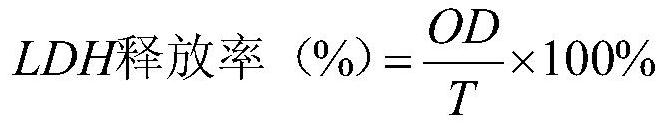

[0044] The prepared chitin nanofibers were placed in 1% glacial acetic acid solution (v / v), and ultrasonically treated for 1 h to prepare a chitin nanofiber solution with a concentration of 2.4 mg / mL. Add Nisin and 0.4% transglutaminase (m / m, based on the dry matter of Nisin) to the above ...

Embodiment 2

[0046] Preparation of S1 chitin nanofibers:

[0047] The chitin powder was dispersed in 33% (w / v) sodium hydroxide and 0.3% sodium borohydride (w / v), in a water bath at 90°C, and magnetically stirred for 4 hours. The solution was suctioned, filtered, and washed with deionized water until the filtrate was clear and colorless. The collected residue was dried in an oven at 45° C. for 1 h, dissolved with 1% (v / v) acetic acid solution, ultrasonically treated for 1 h, allowed to stand for 30 min, and the supernatant was taken out and freeze-dried for 24 h to obtain chitin nanofibers.

[0048] Preparation of S2 transglutaminase-induced cross-linked chitin nanofiber / Nisin composite preservative:

[0049] The prepared chitin nanofibers were placed in 1% glacial acetic acid solution (v / v), and ultrasonically treated for 1 h to prepare a chitin nanofiber solution with a concentration of 2.4 mg / mL. Add Nisin and 0.4% transglutaminase (m / m, based on the dry matter of Nisin) to the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com