Forage grass seed shedding machine

A seed and forage technology, applied in the field of forage seed shedding machine, can solve the problems of low quality of shedding seeds, seeds containing dust and sundries, incomplete shedding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

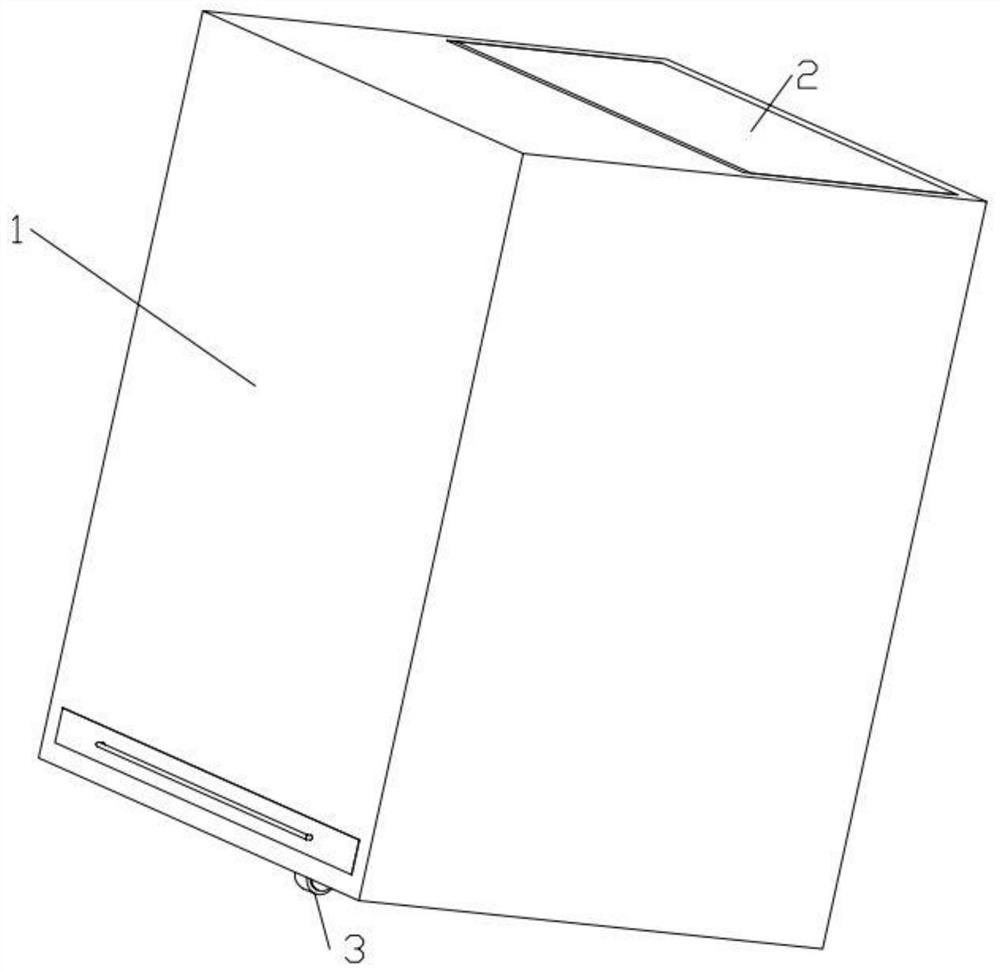

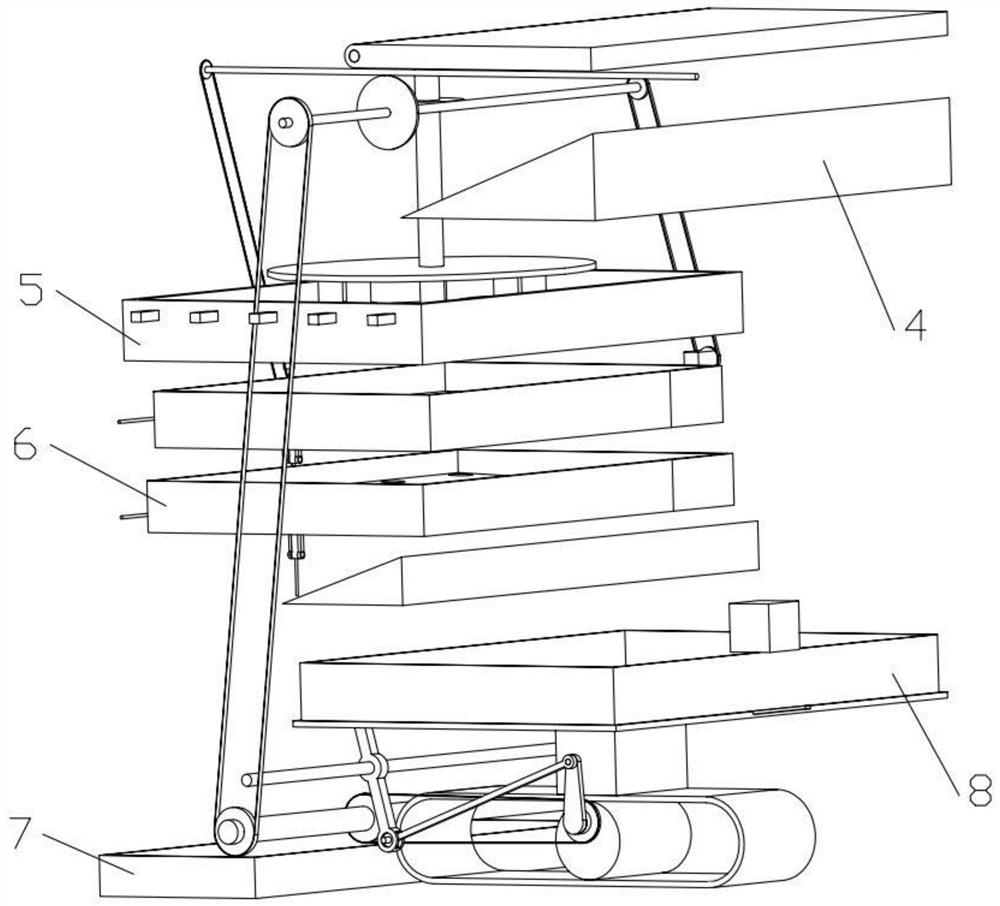

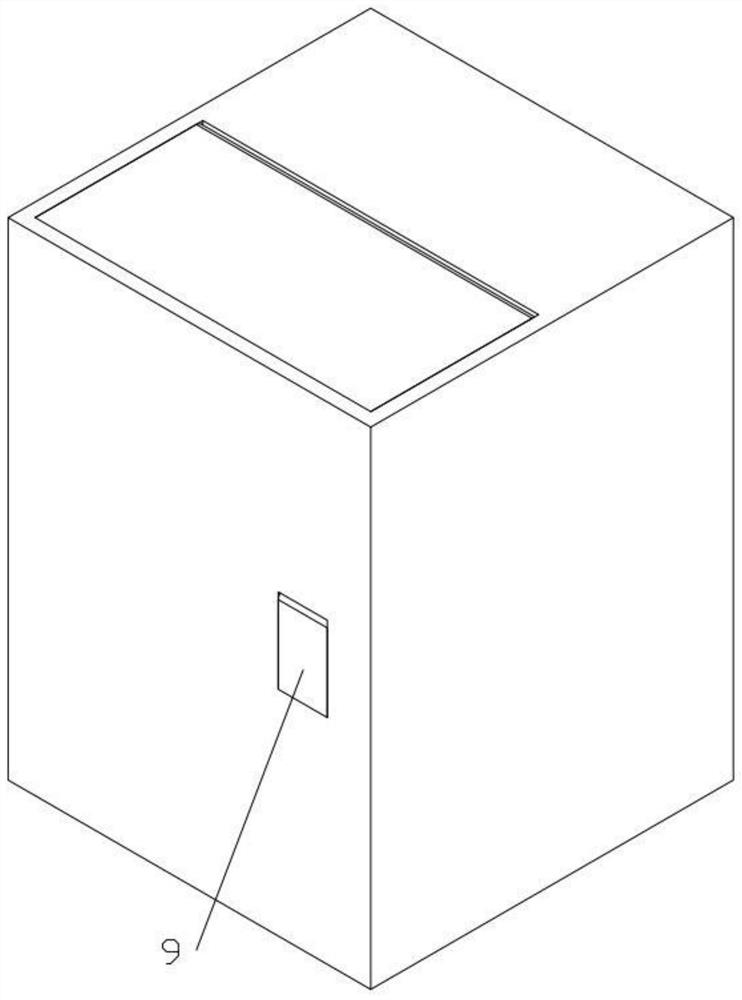

[0031] Combine below Figure 1-13 In order to solve the above-mentioned technical problems, the present invention relates to the technical field of seed treatment, more specifically, a forage seed shedding machine, comprising a box body 1, a feeding door 2, a self-locking universal wheel 3, a sliding plate 4, a twisted seed Device 5, sieve device 6, collection box 7, control door 8 and impurity removal device 9; it is characterized in that: the upper end of the box 1 is hinged with a feed door 2, and the box 1 is also hinged with a control Door 8, the bottom end of the box body 1 is provided with several groups of self-locking universal wheels 3, the corresponding lower end of the described material inlet door 2 is provided with a sliding material plate 4, and the corresponding lower end of the described sliding material plate 4 is provided with twisted Seed device 5, the lower end of described twisted seed device 5 is provided with sieve body device 6, and the bottom end of d...

specific Embodiment approach 2

[0034] Combine below Figure 1-13 Illustrate this embodiment, this embodiment will further illustrate embodiment one, described twist seed device 5 comprises transmission motor 5-1, first twist seed drive pulley 5-2, second twist seed drive pulley 5-3, twist seed Transmission belt 5-4, twister worm 5-5, twister turbine 5-6, first twister shaft 5-7, twister drive wheel 5-8, twister drive disc 5-9, second twister shaft 5-10, twist seed grinding wheel 5-11, twist seed frame 5-12 and connecting block 5-13; the main shaft of the transmission motor 5-1 is provided with a first twist seed drive pulley 5-2, and the first twist seed Seed drive pulley 5-2 is connected with the second twist seed drive pulley 5-3 by twist seed drive belt 5-4, and described second twist seed drive pulley 5-3 is arranged on the twist seed worm screw 5-5, and described twist seed The worm 5-5 meshes with the twist seed turbine 5-6, and the twist seed turbine 5-6 is connected with the first twist seed shaft ...

specific Embodiment approach 3

[0037] Combine below Figure 1-13 This embodiment will be described. This embodiment will further describe the second embodiment. The sieve body device 6 includes a sieve body turbine 6-1, a sieve body worm 6-2, a first sieve body pulley 6-3, a second sieve body Body pulley 6-4, first sieve body drive belt 6-5, first sieve body drive shaft 6-6, third sieve body pulley 6-7, fourth sieve body pulley 6-8, second sieve body Transmission belt 6-9, second sieve body transmission shaft 6-10, first sieve moving rod 6-11, second sieve moving rod 6-12, sieve moving transmission sleeve 6-13, third sieve moving rod 6-14 , the sieve body drive rod 6-15, the second moving rod 6-16, the sieve body 6-17 and the blanking gate 6-18; the twisted seed worm 5-5 is provided with a sieve body turbine 6-1, and the The sieve body turbine 6-1 is meshed with the sieve body worm 6-2, and the first sieve body pulley 6-3 is arranged on the sieve body worm 6-2, and the first sieve body pulley 6-3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com