Metal plate machining workbench and using method thereof

A metal plate and workbench technology, applied in workbenches, manufacturing tools, etc., can solve the problems of loosening of fixing devices, movement of metal plates, and inability to process consistent metal plates, so as to reduce production costs, reduce scrap rate, and effectively fix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

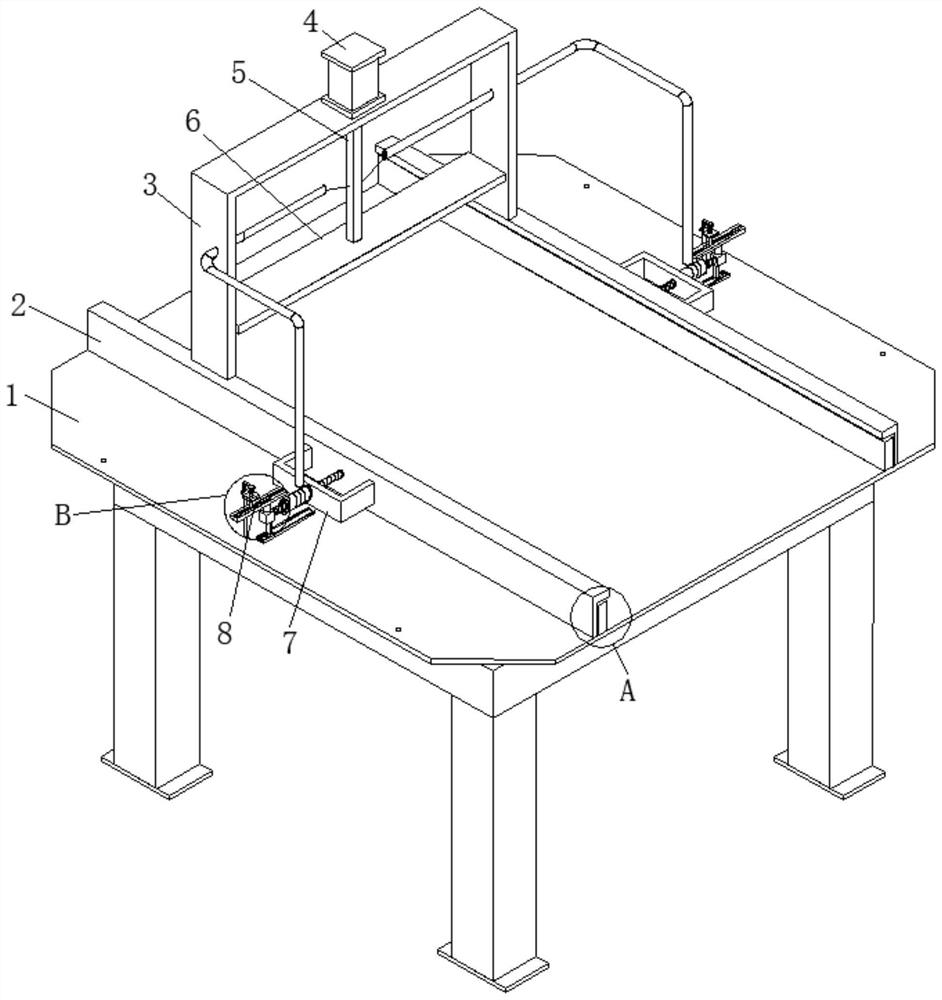

[0043] Attached below Figure 1-6 The present invention is further described with embodiment:

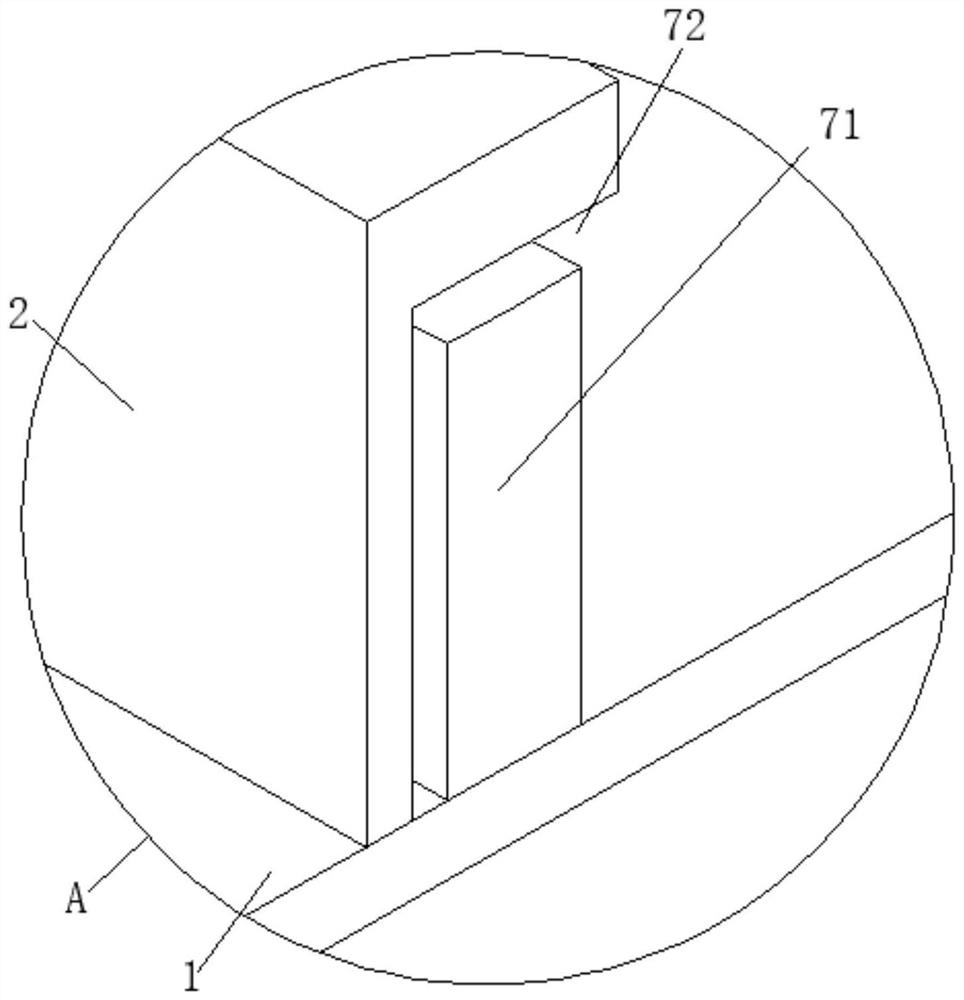

[0044] A metal plate processing workbench, comprising a workbench 1 and a support column 9, four support columns 9 distributed in a matrix are fixedly arranged on the lower plate of the workbench 1, and two vertical limit positions are symmetrically arranged on the workbench 1 plate 2, and a metal plate is used between the two vertical limit plates 2, and the same No. A drive cylinder 4 is fixedly arranged on the horizontal plate of the support plate 3, and the drive cylinder 4 is connected with the cylinder arm 5, and the cylinder arm 5 is movably inserted on the No. 1 U-shaped support plate 3 horizontal plate, and the lower end of the cylinder arm 5 is connected with an upper Pressing plate 6, and upper pressing plate 6 is arranged between two vertical limiting plates 2, in the present invention, by setting two vertical limiting plates 2 on the worktable 1, the setting of two ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com