Semiconductor structure and forming method thereof

A semiconductor, multi-layer structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the accuracy of pattern transfer needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

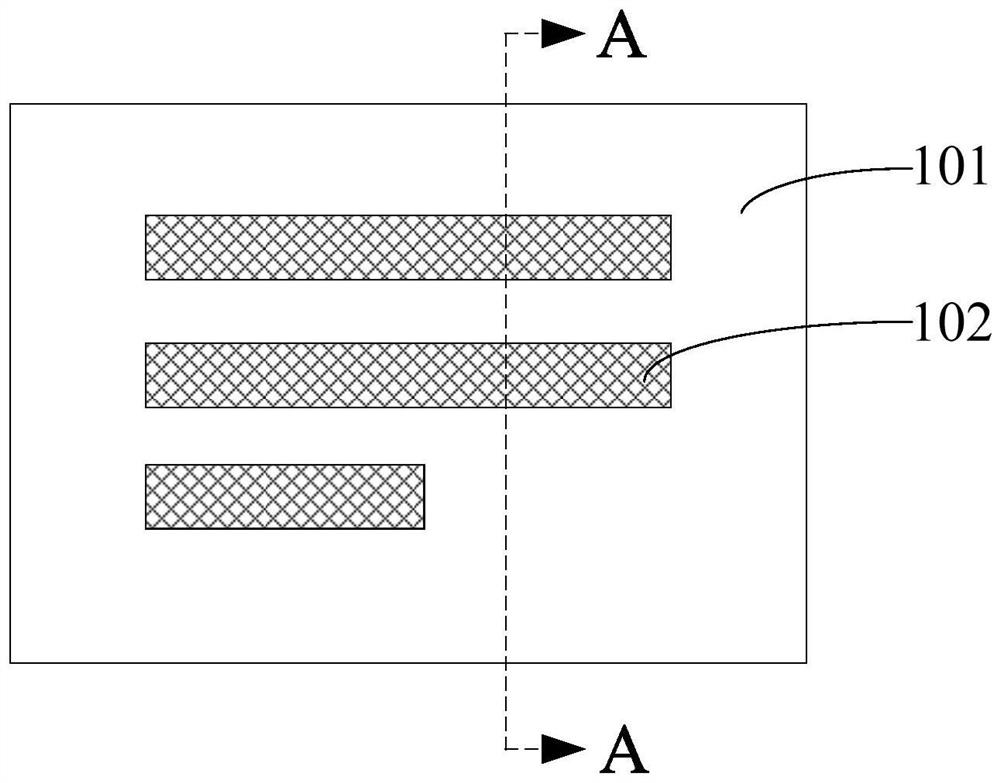

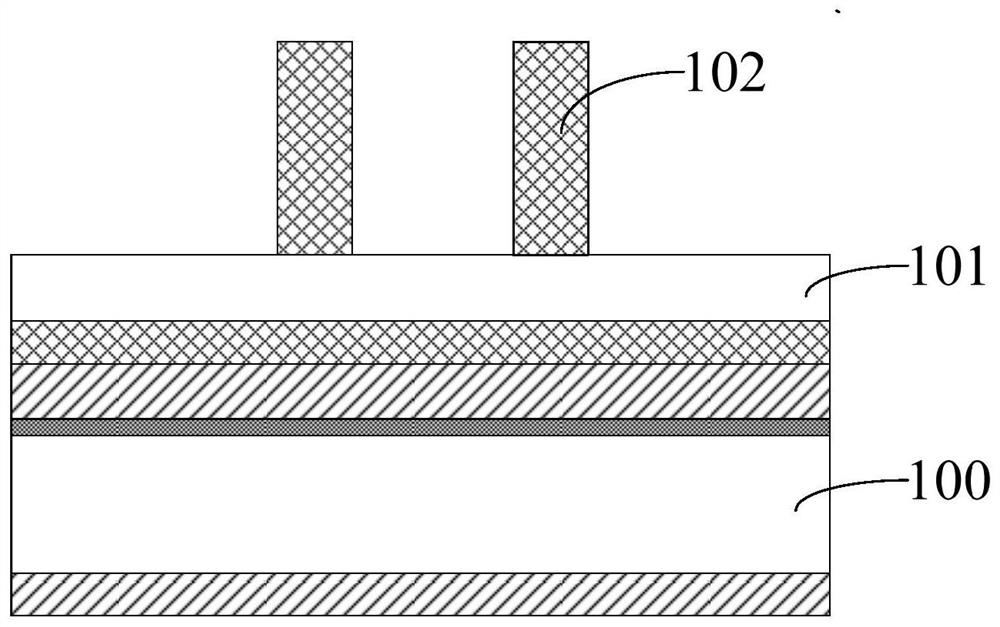

[0031] As mentioned in the background art, in the process of forming a semiconductor structure in the prior art, the accuracy of pattern transfer needs to be improved. The following will combine Figure 1 to Figure 4 Be explained, Figure 1 to Figure 4 It is a structural schematic diagram of each step in the formation process of a semiconductor structure.

[0032] Please refer to figure 1 and figure 2 , figure 2 Yes figure 1 A schematic cross-sectional view along line A-A, providing a layer to be etched 100; forming an initial mask layer 101 on the layer to be etched 100; forming an exposed portion of the initial mask layer 101 on the initial mask layer 101 Graphical structure 102 of .

[0033] Please refer to image 3 and Figure 4 , Figure 4 Yes image 3 A schematic cross-sectional view along line A-A, using the patterned structure 102 as a mask, ion doping treatment is performed on the initial mask layer 101 to form a mask layer (not shown), and the mask layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com