Heat pipe nuclear reactor thermoelectric conversion waste heat direct discharge system and working method

A nuclear reactor and thermoelectric conversion technology, applied in the fields of reactors, nuclear engineering, nuclear power generation, etc., can solve the problems of complex and compact structure, limited space marine environment, limited internal space of underwater equipment, etc., to improve economy, improve concealment, The effect of improving energy utilization efficiency and energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

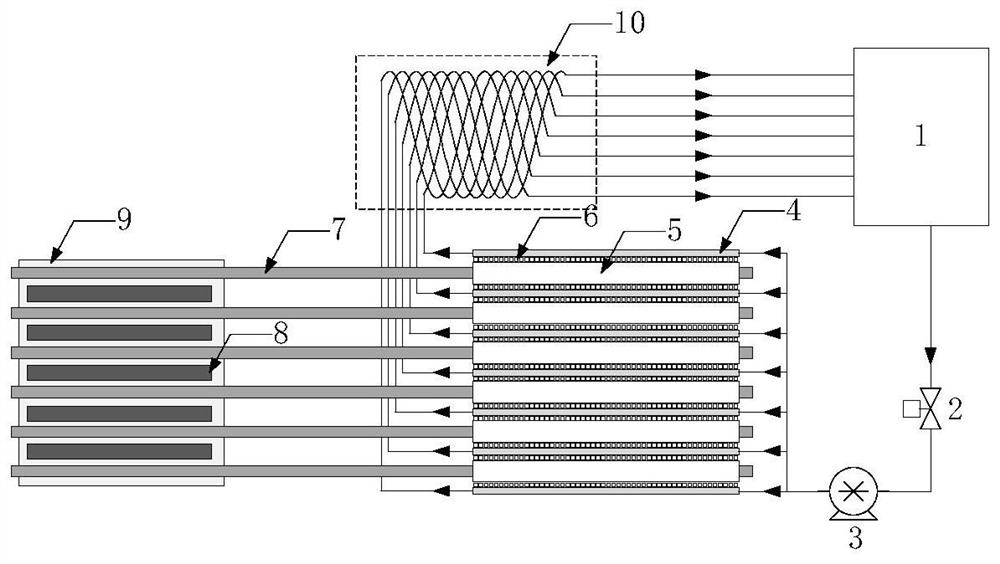

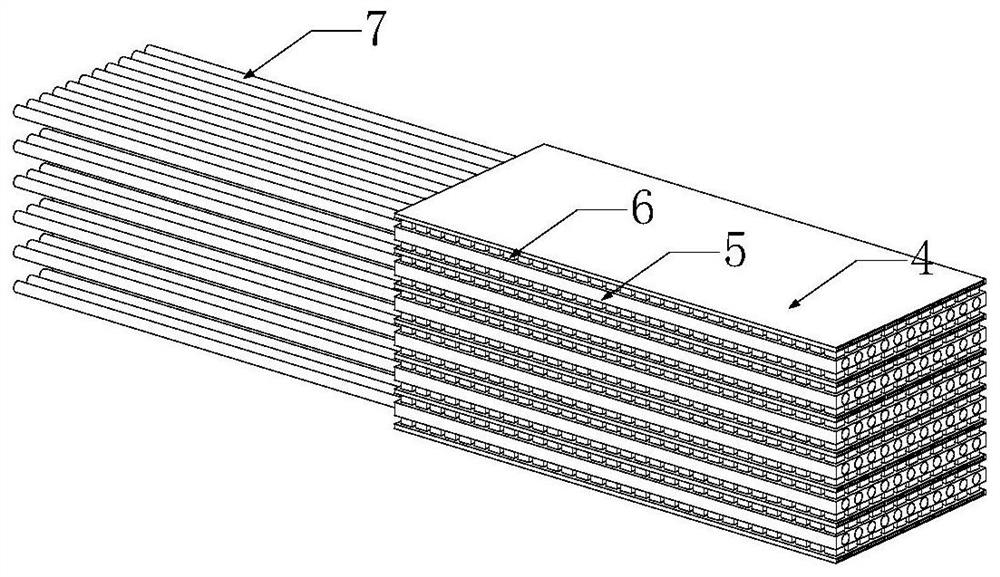

[0023] Such as figure 1 As shown, a heat pipe nuclear reactor thermoelectric conversion waste heat direct discharge system of the present invention includes a water tank 1, the outlet of the water tank 1 is connected to the inlets of a plurality of cold plate heat exchangers 4 through pipelines, and an electric regulating valve 2 and a circulation pump 3 are arranged on the pipelines. The outlet of the cold plate heat exchanger 4 is connected to the inlet of the shell heat exchanger 10 through a pipe, the outlet of the shell heat exchanger 10 is connected to the inlet of the water tank 1, and the shell heat exchanger 10 is placed in seawater; the adjacent cold plate heat exchanger 4 A heat conduction base 5 and a thermoelectric power generation module 6 are provided, one end of a heat pipe 7 of the nuclear reactor is inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com