Application method of bearing mortar coagulant prepared from coal gangue

A technology of bearing mortar and application method, applied in the field of building materials, can solve the problems of complex preparation, high cost, poor fluidity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

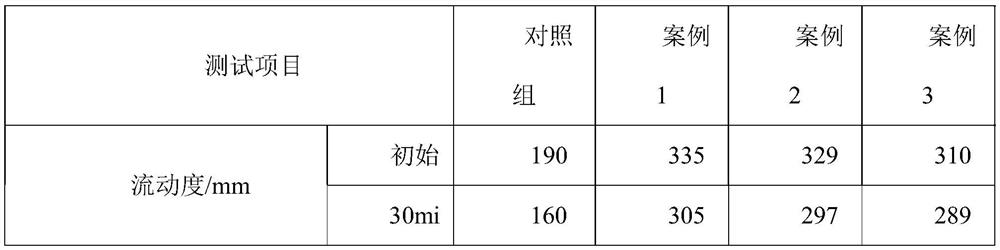

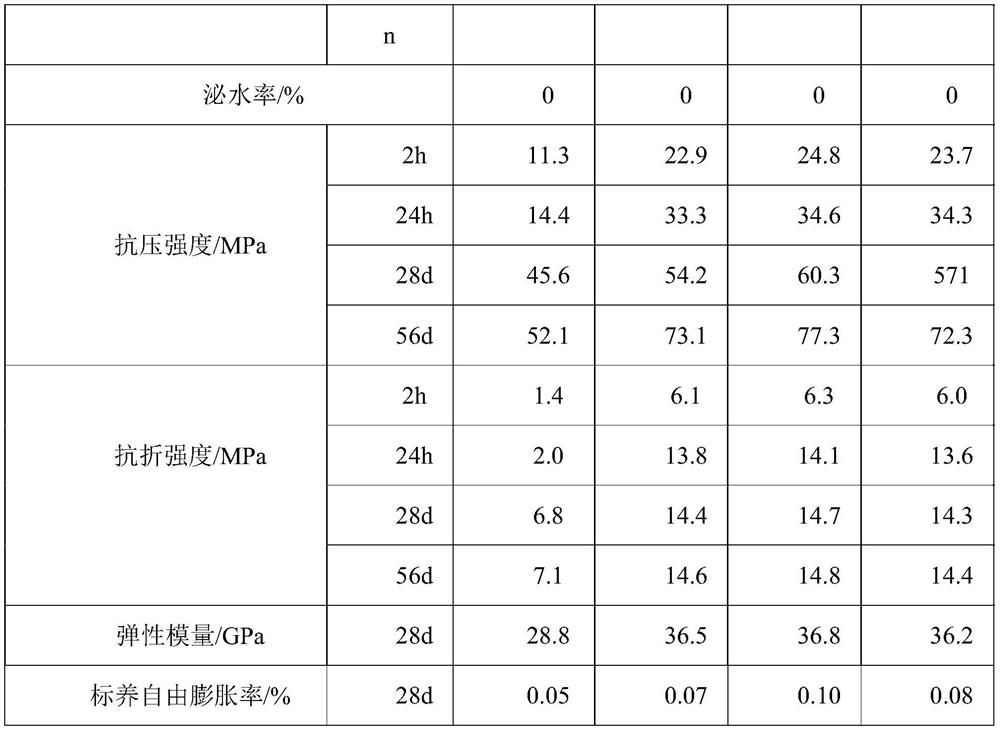

Examples

Embodiment example 1

[0027] Consists of the following raw materials in parts by weight:

[0028] The industrial solid waste coal gangue is put into the crusher for crushing. The particle size of the processed coal gangue is about 5-20 mm, and then the crushed coal gangue is dry-milled to obtain coal gangue powder with a particle size of 100-500 μm. Then the obtained coal gangue powder, water, and zirconia are mixed according to the mass ratio m 1 :m 2 :m 3 =1:5:8, 0.03 parts of surface passivation agent, added to wet grinding equipment for wet grinding for 40-60 minutes, to obtain coal gangue slurry with a particle size of 0.3 μm or less.

[0029] The preparation of the support mortar is as follows in parts by weight: 39 parts of ordinary Portland cement, 6 parts of coal gangue coagulant, 20 parts of 30-40 mesh quartz sand, 30 parts of 40-50 mesh quartz sand, polycarboxylic acid high-efficiency reducing agent 0.2 parts of water agent, 4.55 parts of UEA expansion agent, 0.15 parts of organosilic...

Embodiment example 2

[0031] The industrial solid waste coal gangue is put into the crusher for crushing. The particle size of the processed coal gangue is about 5-20 mm, and then the crushed coal gangue is dry-milled to obtain coal gangue powder with a particle size of 100-500 μm. Then the obtained coal gangue powder, water, and zirconia are mixed according to the mass ratio m 1 :m 2 :m 3 =1:5:8, 0.03 parts of surface passivation agent, added to wet grinding equipment for wet grinding for 40-60 minutes, to obtain coal gangue slurry with a particle size of 0.3 μm or less.

[0032] The preparation of the support mortar is as follows in parts by weight: 43 parts of ordinary Portland cement, 2 parts of coal gangue coagulant, 15 parts of 30-40 mesh quartz sand, 35 parts of 40-50 mesh quartz sand, polycarboxylic acid high-efficiency 0.25 parts of water agent, 4.45 parts of UEA expansion agent, 0.17 parts of organosilicic acid defoamer, and 0.13 parts of polypropylene fiber. The proportioned materials...

Embodiment example 3

[0034] The industrial solid waste coal gangue is put into the crusher for crushing. The particle size of the processed coal gangue is about 5-20 mm, and then the crushed coal gangue is dry-milled to obtain coal gangue powder with a particle size of 100-500 μm. Then the obtained coal gangue powder, water, and zirconia are mixed according to the mass ratio m 1 :m 2:m 3 =1:5:8, 0.03 parts of surface passivation agent, added to wet grinding equipment for wet grinding for 40-60 minutes, to obtain coal gangue slurry with a particle size of 0.3 μm or less.

[0035] The preparation of the support mortar is as follows in parts by weight: 35 parts of ordinary portland cement, 10 parts of coal gangue coagulant, 15 parts of 30-40 mesh quartz sand, 35 parts of 40-50 mesh quartz sand, polycarboxylic acid high-efficiency 0.15 parts of water agent, 4.50 parts of UEA expansion agent, 0.25 parts of organosilicic acid defoamer, and 0.1 part of polypropylene fiber. The proportioned materials w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com