Carbon-based metal monatomic composite material as well as preparation method and application thereof

A composite material and metal-based technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. Problems such as the industrial application of single-atom materials, to achieve the effect of improving catalytic activity and cycle stability, no secondary pollution, and conducive to large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a carbon-based metal single-atom composite material, comprising the following steps:

[0037] mixing coffee grounds and soluble metal salts for metal loading to obtain a composite material precursor; the soluble metal salts are used in the form of a soluble metal salt solution;

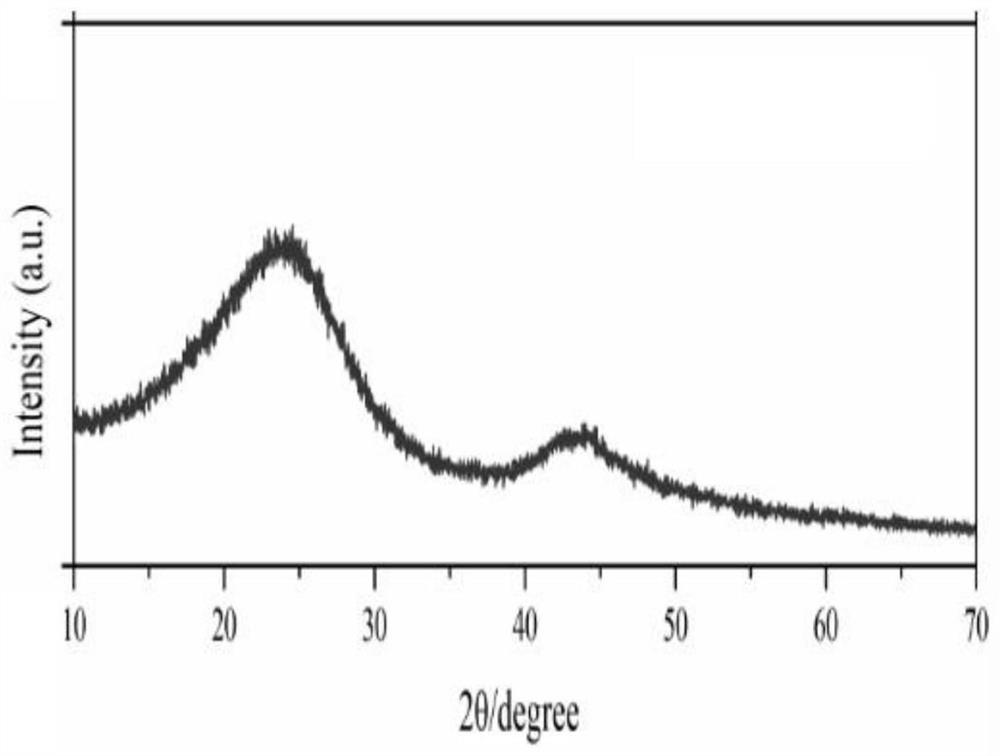

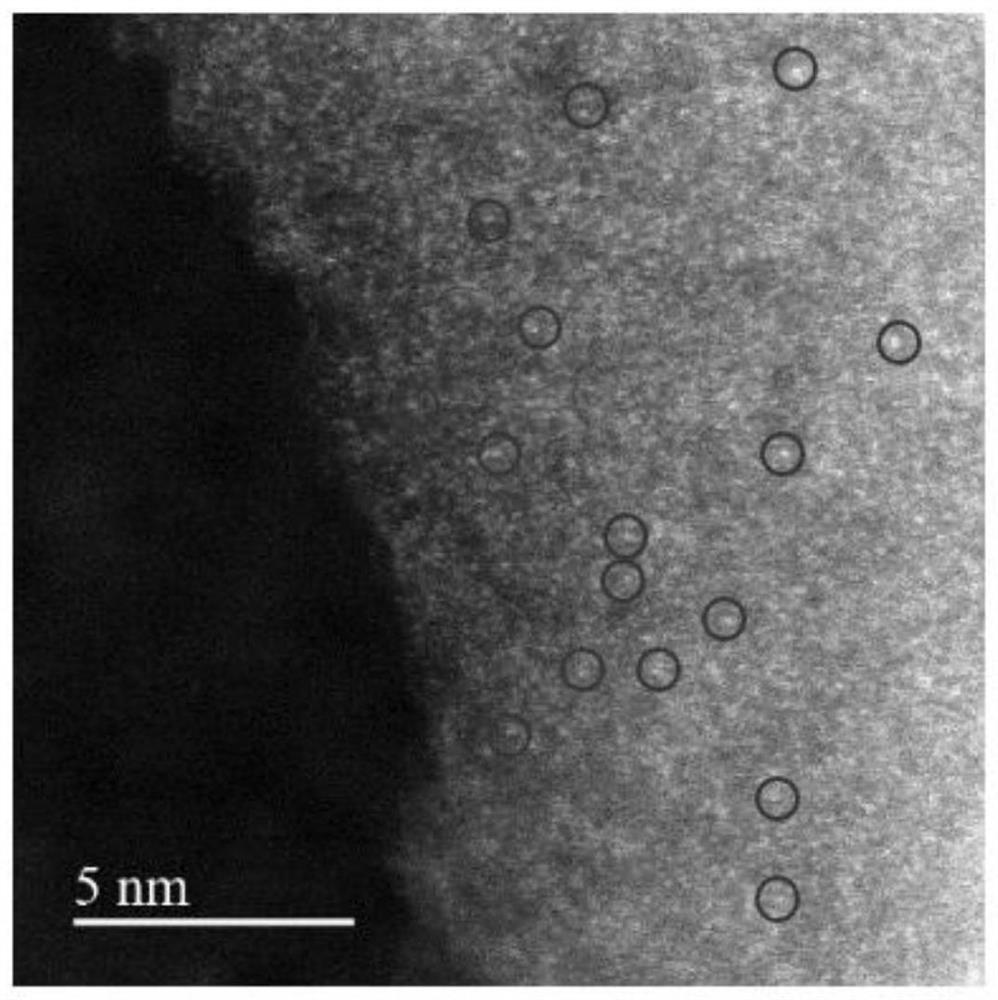

[0038] The composite material precursor is subjected to anaerobic pyrolysis to obtain the carbon-based metal single-atom composite material.

[0039] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0040] The invention mixes coffee grounds and soluble metal salts to carry out metal loading to obtain a composite material precursor.

[0041] In the present invention, the particle size of the coffee grounds is preferably ≤100 mesh; the source of the coffee grounds is not specifically limited in the present invention, and is specifical...

Embodiment 1

[0059] The raw material of coffee grounds in this example is the filter residue of a household coffee machine; the obtained coffee grounds raw material was washed with 50 times the volume of water, and then suction-filtered, and the filter residue was dried in a blast drying oven at 80° C. for 8 hours. Use a small pulverizer to pulverize the dried coffee grounds until the biomass particles obtained by pulverization can pass through a 100-mesh sieve, and the under-sieve is coffee grounds;

[0060] Immerse the coffee grounds in a cobalt nitrate aqueous solution with a concentration of 3.6mmol / L, the mass ratio of the coffee grounds to the cobalt nitrate aqueous solution is 1:15, shake at room temperature for 24 hours, and the oscillation speed is 200rpm; suction filter the mixed system, and place the filter residue in Dry in a forced air oven for 12 hours at 80°C to obtain a composite material precursor for future use.

[0061] Determination of the cobalt content in the composit...

Embodiment 2

[0085] The coffee grounds in this example come from the waste of the commercial coffee shop Luckin. The same preparation method as in Example 1, except that the soluble metal salt is iron salt, and the anaerobic pyrolysis temperature is 700°C. The content of iron in the prepared carbon-based iron single-atom material is 2.92mg / g.

[0086] Performance Testing

[0087] Add 100 times the mass of sulfuric acid with a concentration of 1 mol / L to the carbon-based iron single-atom composite material prepared in Example 2, measure the dissolution of iron in the supernatant after shaking for 4 hours, and the dissolution rate is less than 0.1%, which proves that iron is mainly based on stable It exists in the form of single atoms, and there are almost no nanoparticles of iron element or oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com