Composite material fixing shell for spray pipe and based on 3D printing

A technology of composite materials and fixed shells, applied in 3D object support structures, additive processing, jet propulsion devices, etc., can solve the problems of shortened manufacturing cycle and reduced quality, achieve short manufacturing cycle, improve mass ratio, and reduce structure quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

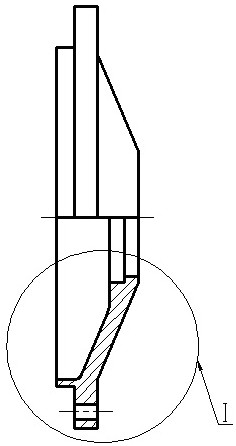

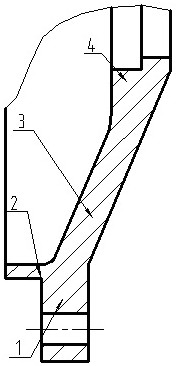

[0014] as attached figure 1 As shown, a 3D printing-based composite material fixed housing for the nozzle is composed of four parts: the flange section 1, the convex mouth section 2, the cone section 3 and the platform stage 4.

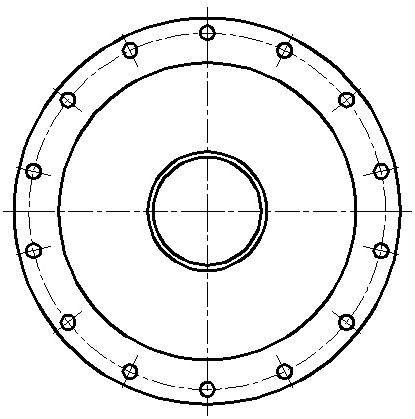

[0015] as attached figure 2 and 3 As shown, the flange section 1 is a cylindrical structure with equal wall thickness, and there are several round holes evenly distributed on the upper surface of the end surface;

[0016] The wall thickness of the flange section 1, the number of round holes on the end surface, the diameter of the holes and the diameter of the distribution circle can be adaptively adjusted according to the index requirements.

[0017] The convex stop section 2 is a short cylinder with equal wall thickness and is perpendicular to one end of the flange section at 90°;

[0018] The cone section 3 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com