A sheet metal marking machine with adjustable marking depth

A metal sheet and adjustable technology, applied in the field of marking machines, can solve the problems of metal sheet damage and the inability to automatically adjust the depth of marking, and achieve the effects of avoiding excessive thinning, reducing product scrap rate and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

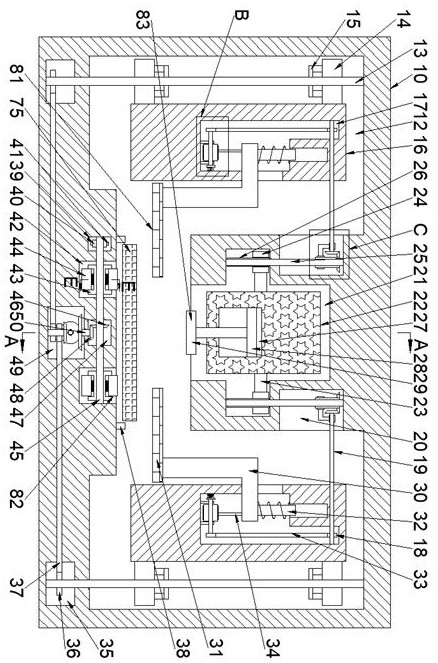

[0020] Beneficially, the fastening measurement device 81 also includes a device disposed inside the body 10 and located in the working cavity 12

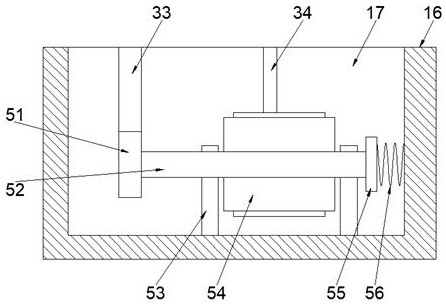

[0021] Beneficially, the conveying mechanism 82 includes a structure that is fixedly arranged on the bottom wall of the working chamber 12 and symmetrically distributes the gold

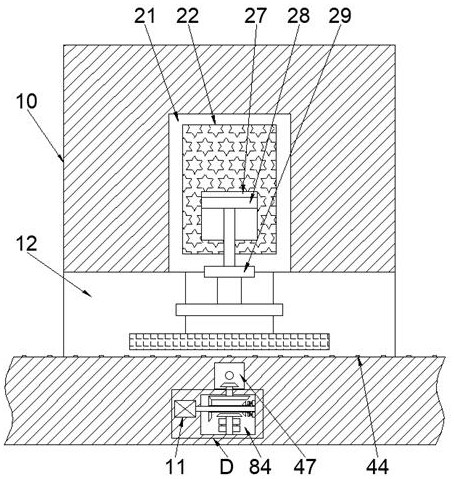

[0022] Beneficially, the marking device 83 includes a downward opening provided on the top wall of the working chamber 12 and the working chamber 12

[0023] Beneficially, the transmission device 84 includes a device disposed inside the body 10 and located under the third transmission cavity 47

[0024] The fixed connection method described in this embodiment includes but is not limited to bolting, welding and other methods.

[0027] When the device of the present invention is in operation, the metal sheet 75 is placed between the left and right limit blocks 38.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com