A kind of manufacturing process of color steel corrugated board

A manufacturing process and corrugated board technology, which is applied in the field of color steel corrugated board production and manufacturing technology, can solve the problems of reducing the success rate of roll forming, the thin steel sheet cannot protrude, and the thin steel sheet cannot shrink, so as to reduce the working steps, Avoid shrinkage and improve the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

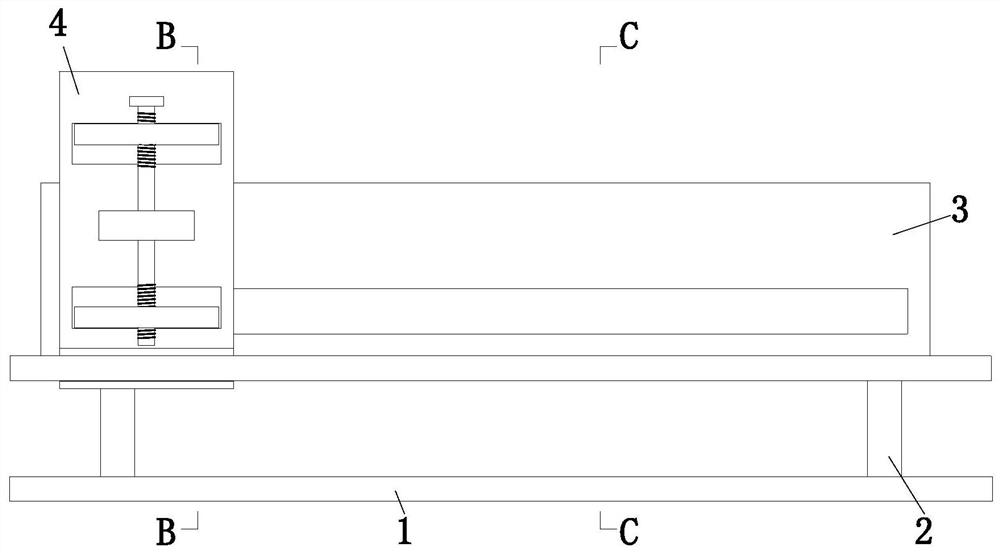

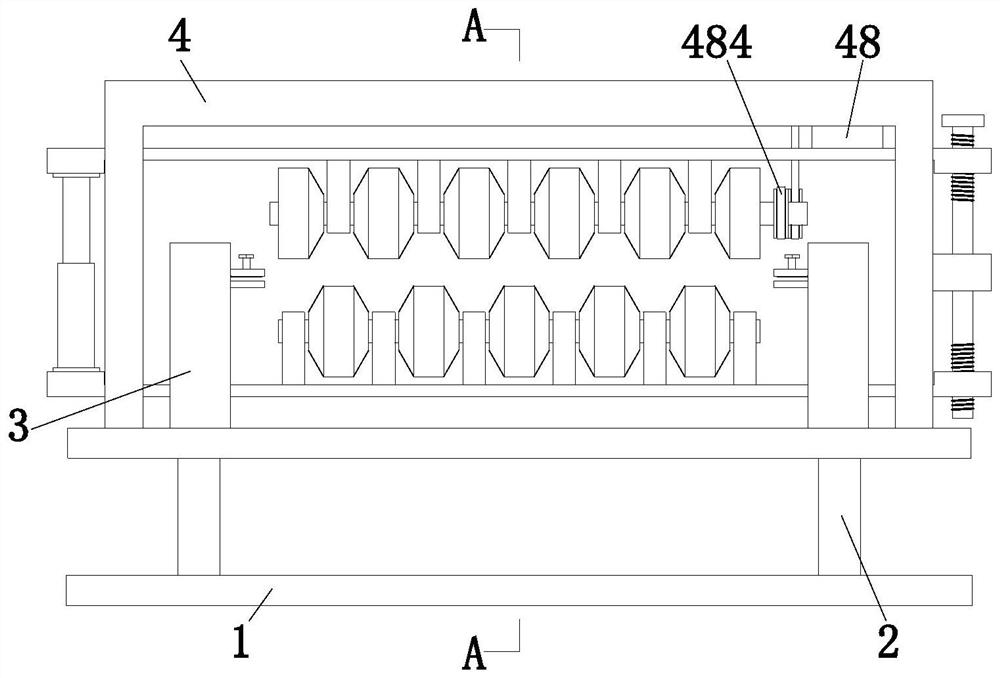

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

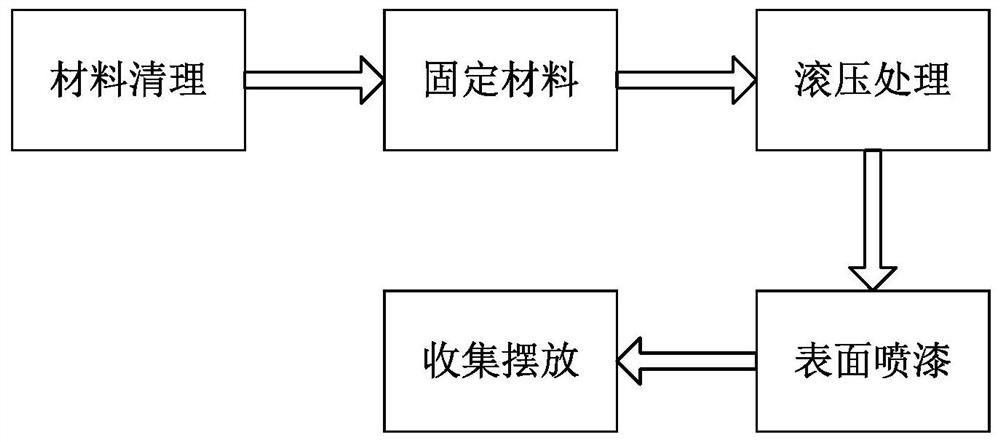

[0035] like Figure 1 to Figure 8 As shown, in order to achieve the above object, the present invention adopts the following technical solutions, a color steel corrugated board production and manufacturing process, which uses a color steel corrugated board production and manufacturing equipment, the corrugated board production and manufacturing equipment includes a base plate 1, a support platform 2. The clamping device 3 and the rolling device 4 use the above-mentioned corrugated board production and manufacturing equipment to manufacture the color steel corrugated board. The specific method is as follows:

[0036] S1. Material cleaning: manually clean the produced thin steel sheet to remove stains and debris on its surface;

[0037] S2. Fixing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com