Split type tundish turbulence inhibitor

A turbulent flow controller and controller technology, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of large impact on the ladle slag-gold interface and limited improvement of the flow field, so as to promote the growth of collision polymerization, Effect of increased turbulent kinetic energy dissipation rate and flow stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

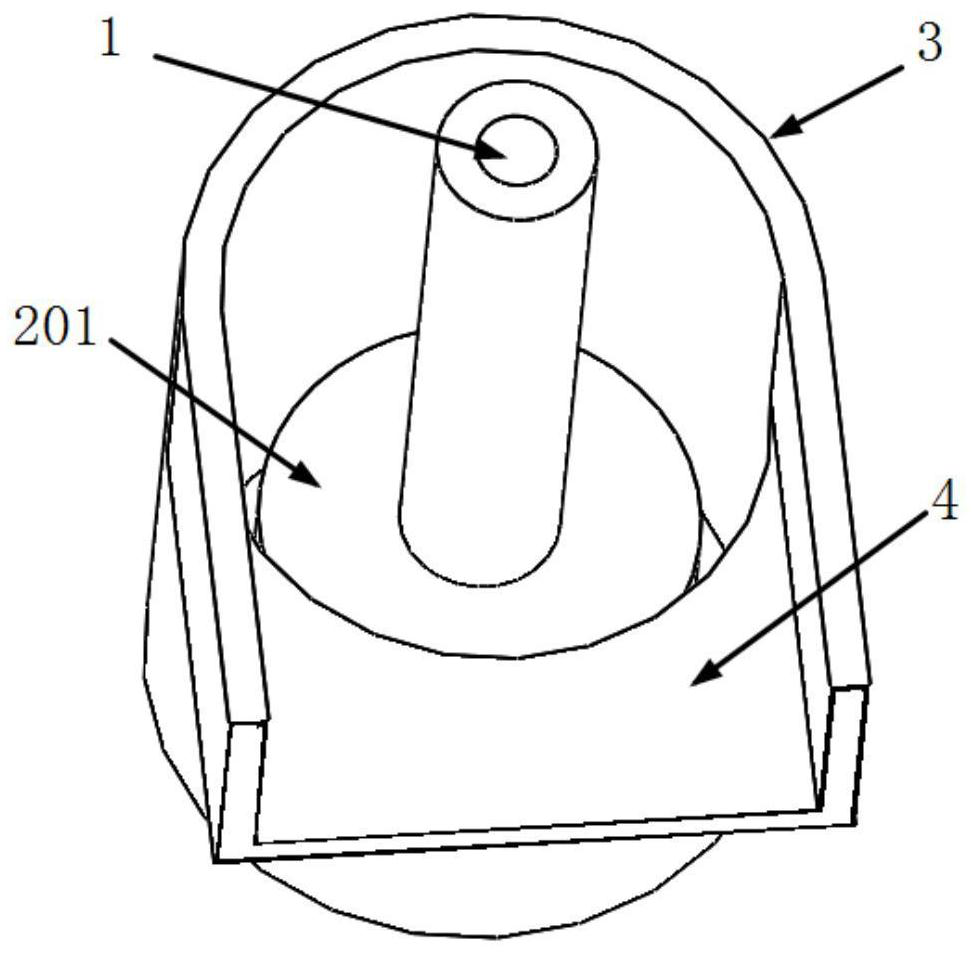

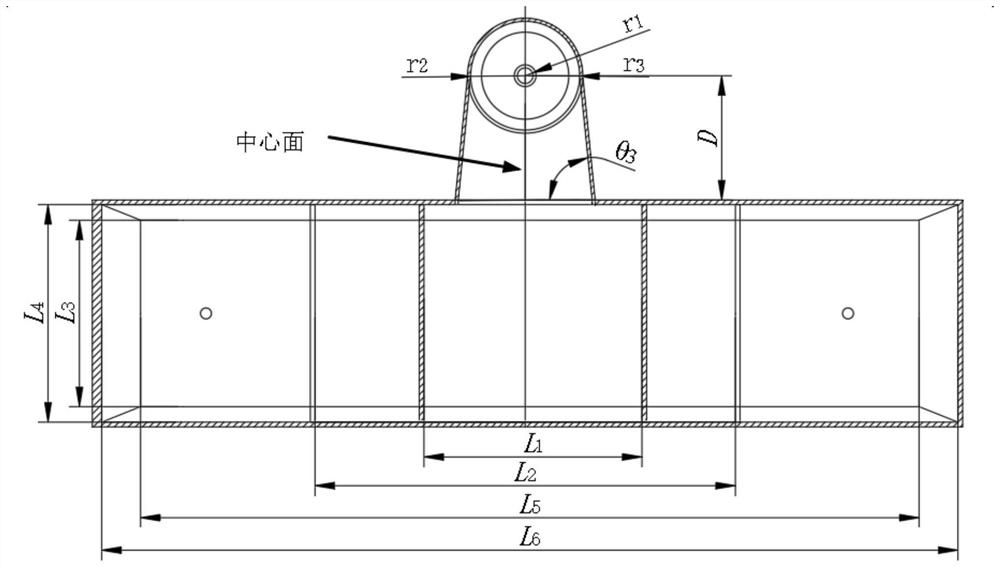

[0037] The metallurgical effect of the split tundish turbulence controller is studied by using water model experiments and numerical simulations. The length of the top of the tundish body 8 is L 6 =5500mm, width L 4 =1400mm, the length of the bottom of the tundish body 8 is L 5 =5000mm, width L 3 =1200mm, tundish body 8 height H 5 =1300mm (the size shown is only the fluid area of the tundish, not including the refractory part); the inner diameter d of the external flow control device 6 =700mm, height H 1 =800mm; the length D of the groove 4 between the tundish body 8 and the external flow control area 3=550mm, the angle θ between the side wall of the groove 4 and the tundish body 8 3 =90°, height H 6 =200mm; inner diameter d of shroud 1 1 =100mm, the height H of the upper part of the controller 201 2 =110mm, the included angle θ 1 =20°, the height H of the lower part of the controller 202 3 =90mm, the included angle θ 2 =20°; chamber 203 height H 4 =200mm. During...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com