A slurrying process of diatomite filter for lithium battery copper foil system

A diatomite filter, electrolytic copper foil technology, applied in the direction of filtration separation, electrolysis process, filtration circuit, etc., can solve the problems of electrolyte substance concentration imbalance, filter system flow drop, unqualified copper foil, etc., to improve copper foil Foil yield, reduce fluctuations, avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

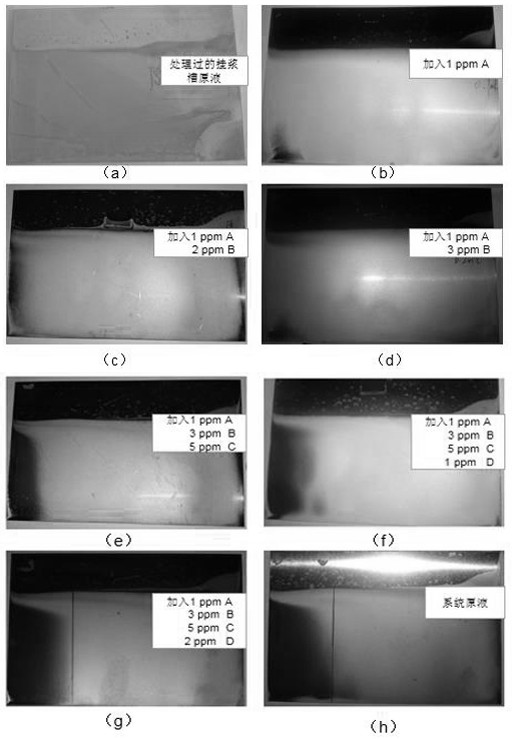

Embodiment 1

[0026] In the production of electrolytic copper foil, in addition to copper sulfate, other additives are added to the electrolyte, such as hydroxyethyl cellulose, sodium P-alcohol thiopropane sulfonate, PN polyethyleneimine alkyl salt, etc. These additives together with copper sulfate constitute the solute environment of the copper foil electrolyte. However, during the slurrying process, an oxidizing agent needs to be added in advance to oxidize and remove impurities in the electrolyte. At this time, the initially added organic additives will also be degraded, resulting in the inconsistency of the solute composition of the slurrying solution with the electrolyte used for production. In order to avoid fluctuations in the solution environment during the slurrying process, it is necessary to re-add organic additives after adding oxidants to remove impurities.

[0027] Additives commonly used in the production of copper foil include A, B, C, and D. The A is HEC hydroxyethyl cellul...

Embodiment 2

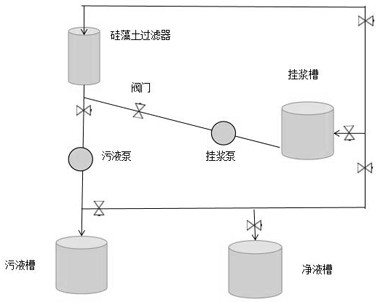

[0035] A slurrying process of a diatomite filter for an electrolytic copper foil system (see the schematic diagram of the device connection involved in the process figure 2 ), including the following steps:

[0036] 1) Put the copper sulfate electrolyte to be treated in the slurry tank, the volume of the slurry tank is 30m 3 , the liquid level is 50% of the volume of the slurry tank; add 50 liters of hydrogen peroxide, the volume ratio of hydrogen peroxide to the electrolyte to be treated is 0.33%; use hydrogen peroxide to decompose the organic matter or impurities in the electrolyte;

[0037] 2) Add a certain amount of additives A, B, C, and D for production in proportion, among which the amount of A added is 2 ppm, the amount of B added is 4 ppm, the amount of C added is 6 ppm, and the amount of D added is 2 ppm;

[0038] 3) Turn on the stirring pump of the slurry tank, add diatomite into the slurry tank, the amount of diatomite added is 150kg, and add in 10 times; after t...

Embodiment 3

[0044] A slurrying process of a diatomite filter for an electrolytic copper foil system, specifically comprising the following steps:

[0045] 1) Add copper sulfate electrolyte to be treated in the slurry tank, the volume of the slurry tank is 30m 3 , the liquid level is 80% of the volume of the slurry tank; add 50 liters of hydrogen peroxide, the volume ratio of hydrogen peroxide to the electrolyte to be treated is 0.21%, and use hydrogen peroxide to decompose the organic matter or impurities in the electrolyte;

[0046]2) Add a certain amount of additives A, B, C, and D for production in proportion, among which the amount of A added is 3 ppm, the amount of B added is 6 ppm, the amount of C added is 9 ppm, and the amount of D added is 3 ppm;

[0047] 3) Turn on the stirring pump of the slurry tank, add diatomite into the slurry tank, the amount of diatomite added is 150kg, add in 10 times, each cycle time is 4h;

[0048] 4) Turn on the slurry pump, so that the slurry slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com