Constant-state pulp distribution forming device of thick-pulp-method reconstituted tobacco special for heating cigarettes

A forming device and technology for reconstituted tobacco leaves, applied in the fields of tobacco, application, and preparation of tobacco, can solve the problems of clogging the bottom of the scraper, fluctuating sensory quality, high operating pressure, etc., and achieve quantitative stability, improve stability, and increase paper yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other drawings according to these drawings without any creative effort.

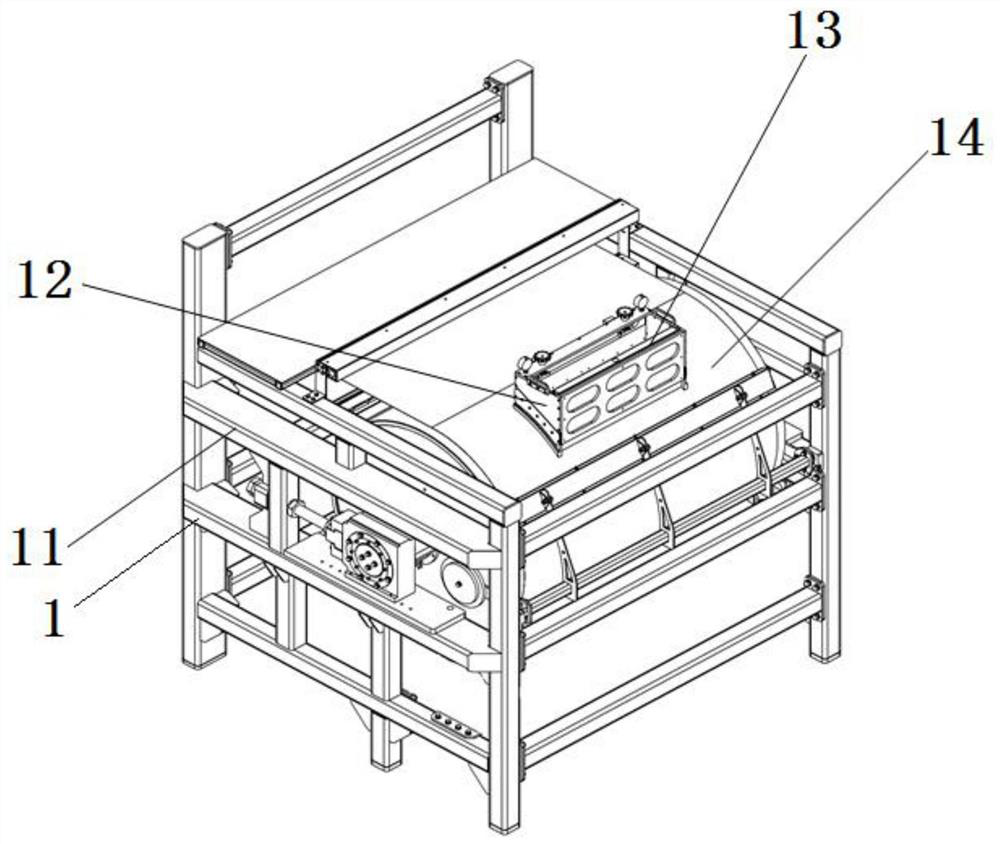

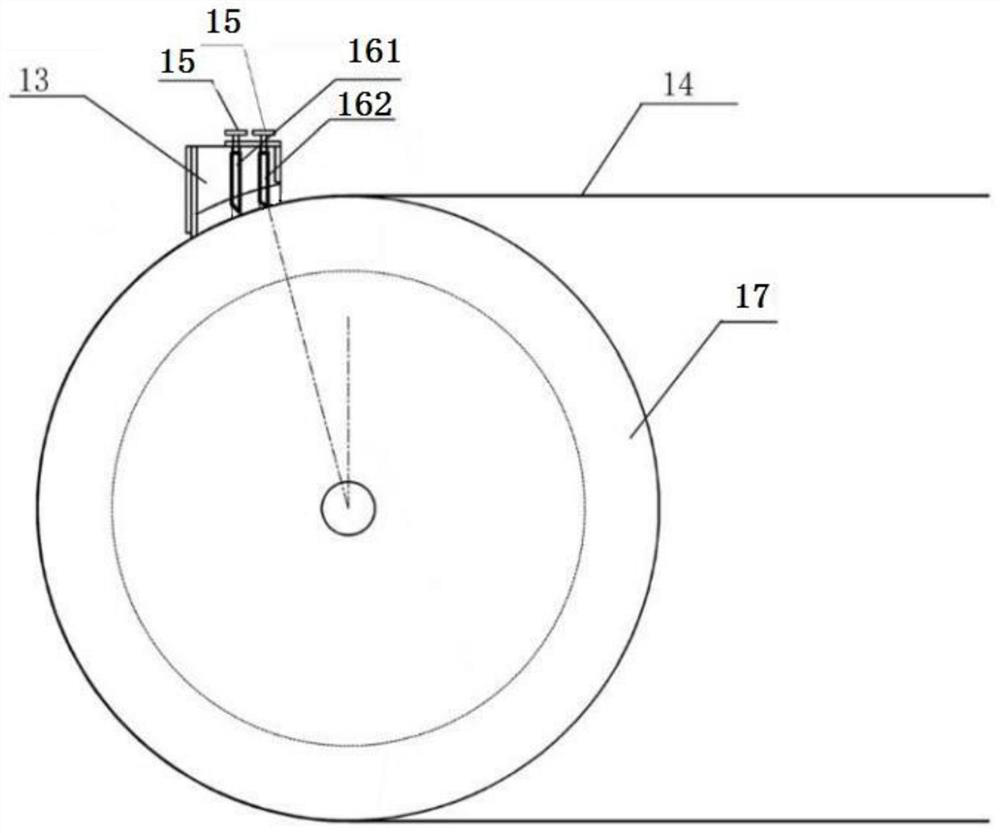

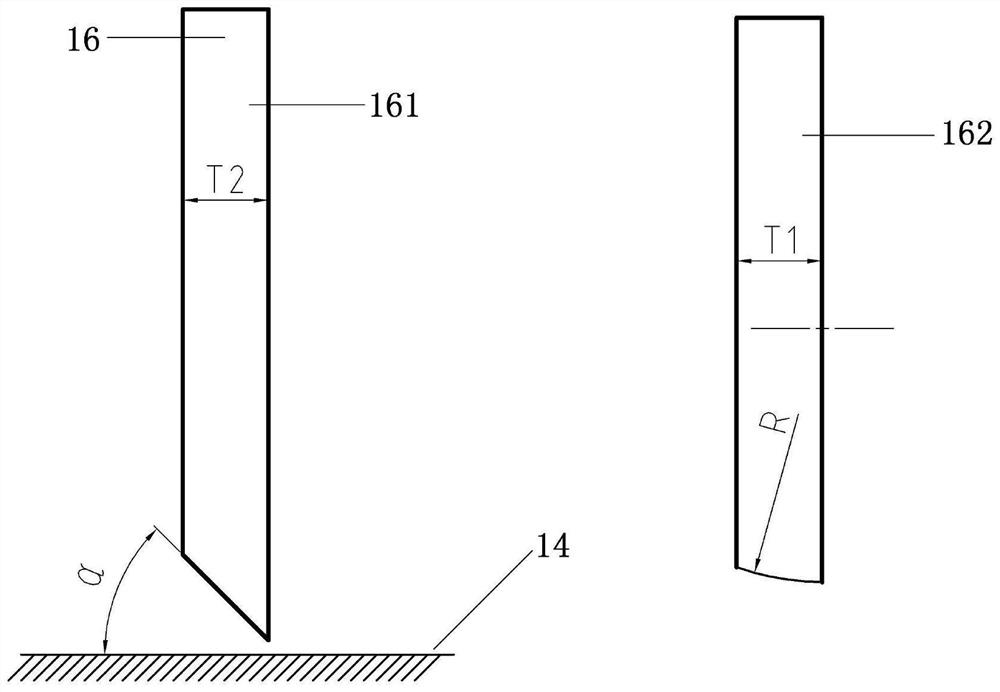

[0049] Such as Figure 1-5 , the present embodiment provides a constant-state slurry forming device for reconstituted tobacco leaves by the thick slurry method for heating cigarettes, which includes a follow-up tape casting forming unit 1, a curtain feeding unit 2, and a release agent roller coating unit 3;

[0050] The follow-up tape casting unit 1 includes a frame 11, a casting box 13, a forming steel belt 14, and a hub 17; the hub 17 is fixed on the frame 11, and the forming steel belt 14 follows the The hub 17 rotates and moves downstream; the side wall of the casting box 13 is the side plate 12 of the casting box, and the casting box 13 is placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com