Travelling wave tube integrated power supply

A technology of integrated power supply and traveling wave tube, which is applied in the direction of electrical components, modification through conduction and heat transfer, and circuit arrangement on the support structure, etc. It can solve the problems of inability to meet the needs of miniaturized applications, high driving voltage, and inability to meet development needs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

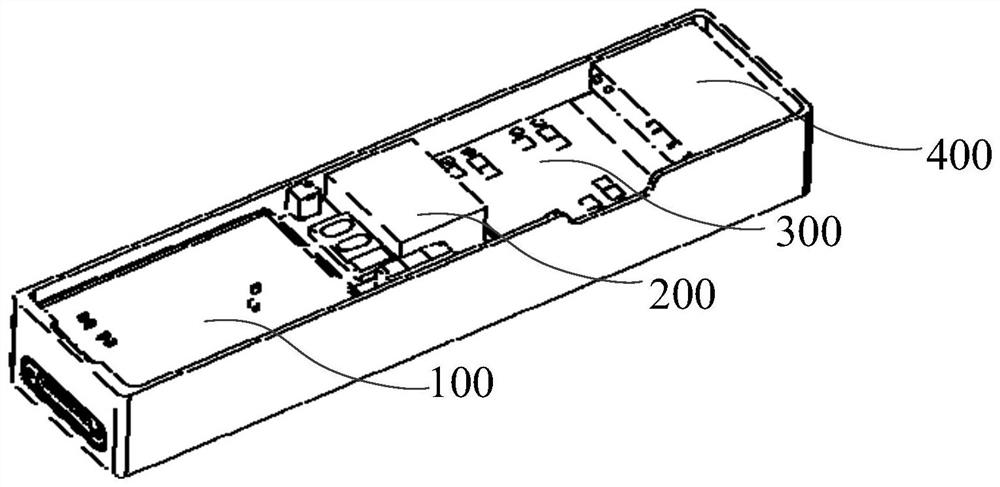

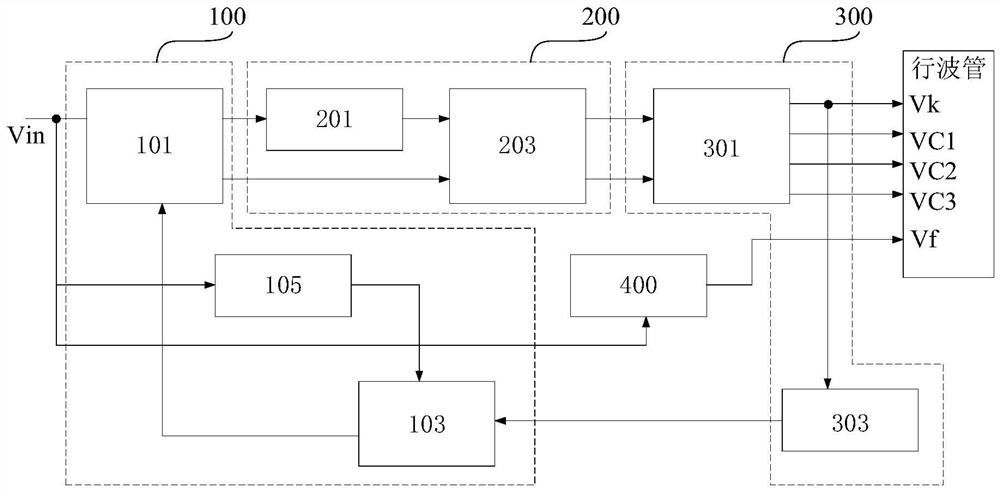

[0026] An embodiment of the present invention provides a traveling wave tube integrated power supply, which includes first to fourth circuit boards stacked in sequence, the first circuit board is provided with an inverter module, the second circuit board is provided with a boost module, and the second circuit board is provided with a booster module. A rectifier module is arranged on the third circuit board, and a filament module is arranged on the fourth circuit board, wherein

[0027] The inverter module is used to conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com