A kind of preparation technology of carbon-based supercapacitor

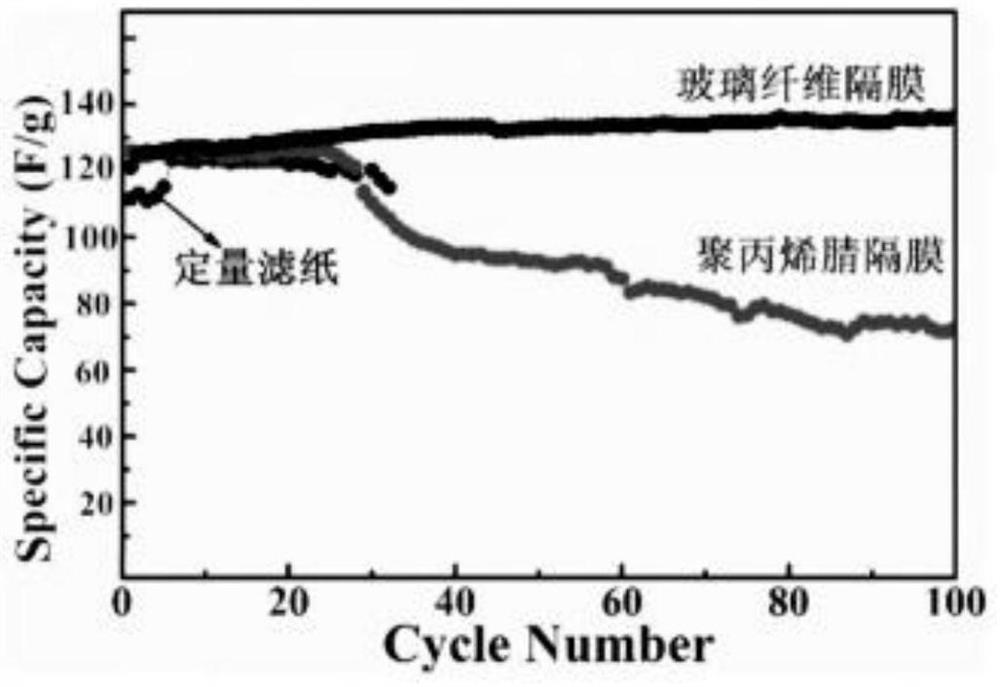

A technology of supercapacitor and preparation process, which is applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor separators, hybrid capacitor electrodes, etc. and other problems, to achieve excellent cycle performance, reduce service life, and facilitate migration and diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

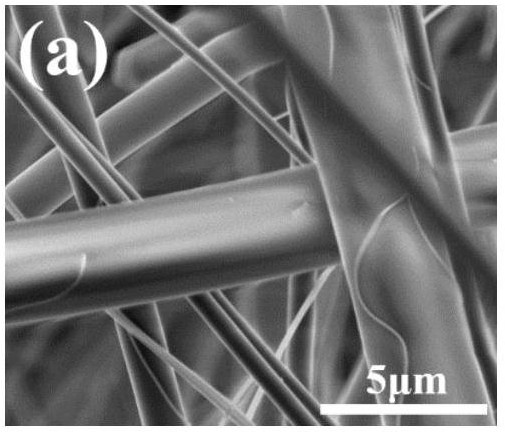

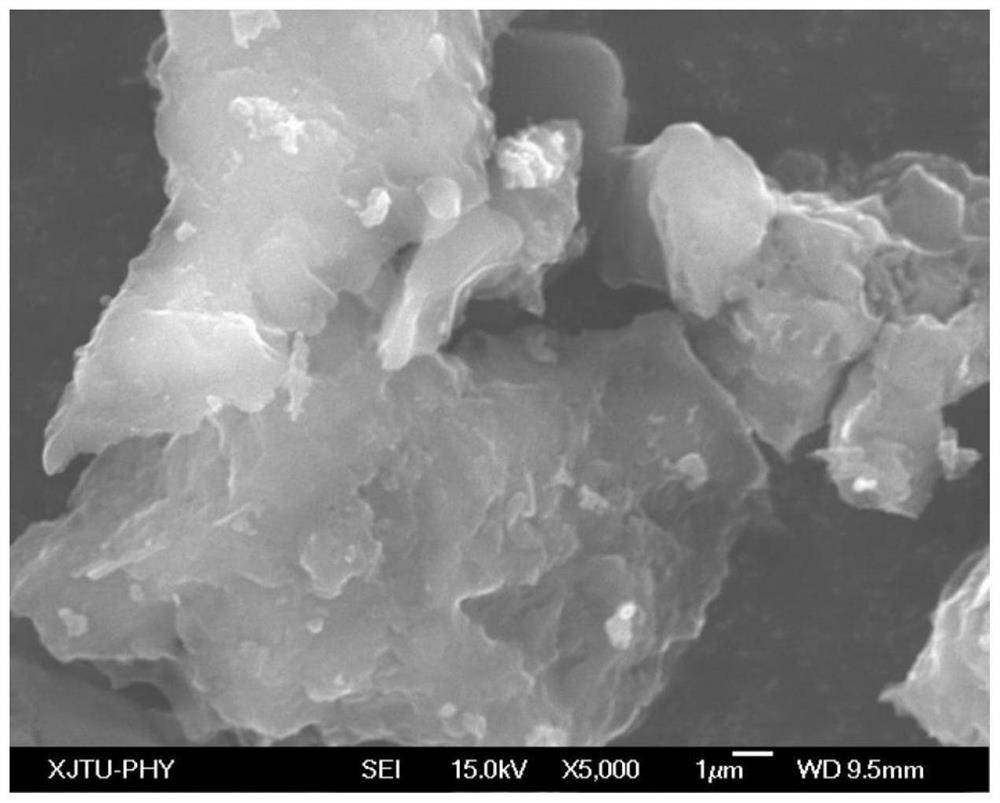

[0034] The present invention is achieved through the following technical scheme: a preparation process of carbon-based supercapacitor, which mainly uses a composite material composed of carbon and manganese dioxide, and sequentially undergoes current collector pretreatment, pulping, mixing, coating, Drying and cutting the sheets to obtain electrode sheets of supercapacitors, preparation of electrode sheets and preparation of electrode materials.

[0035] The preparation of electrode sheet comprises the following steps:

[0036] 1) Pretreatment of corroded aluminum foil current collector: cut 8cm×20cm aluminum foil, soak in alcohol, perform ultrasonic treatment for 30min, take out the aluminum foil, wipe with alcohol cotton, remove oil, and dry in a cool environment;

[0037] 2) Pulping: Mix the binder PVDF, conductive agent carbon black and NMP uniformly in a mass ratio of 7:3:1 to obtain a pulping material;

[0038] 3) Mixing: After uniformly mixing the pulping materials in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com