Smelting process of carbon nanotube reinforced aluminum matrix composite

A technology of carbon nanotubes and reinforced aluminum base, which is applied in the field of aluminum alloy preparation, can solve the problems of weak interface bonding, serious chemical reaction, and floating of carbon nanotubes, and achieve the effect of improving surface tension, high product strength, and eliminating oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

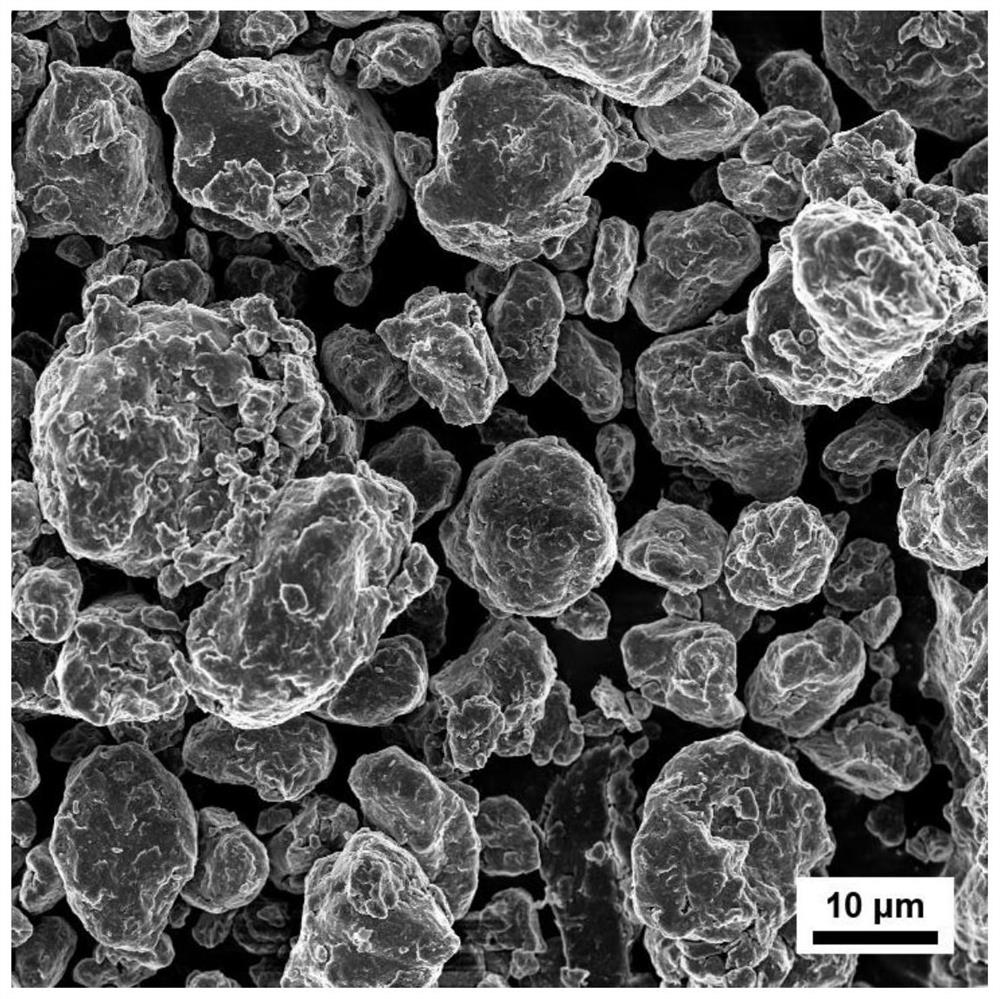

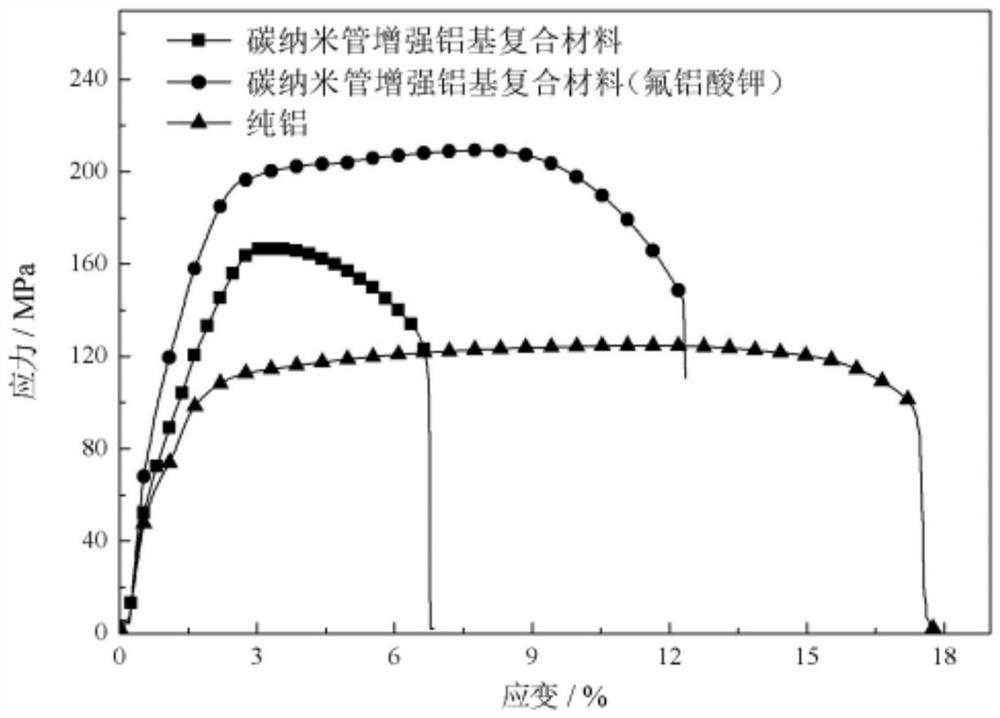

[0022] Example 1, see Figure 1 to Figure 2 :

[0023] The invention provides a smelting process of a carbon nanotube reinforced aluminum matrix composite material, comprising the following steps:

[0024] (1) Weigh a certain amount of 50g K 3 AlF 6 , 50g of carbon nanotubes, and 400g of aluminum powder were mixed and dispersed by ball milling in a planetary ball mill for 5 hours, the ball milling medium was agate balls, and the rotating speed was 400r / min to obtain a carbon nanotube-aluminum mixed powder with a mass fraction of carbon nanotubes of 10wt.%. ;

[0025] (2) Put the mixed powder in the mold and cold-press molding under 200MPa pressure to make a prefabricated block of φ60mm×20mm, and obtain a carbon nanotube-aluminum prefabricated block;

[0026] (3) Press the carbon nanotube-aluminum prefabricated block into the molten aluminum through a bell jar, and at the same time, slowly stir the aluminum melt (60r / min), heat-preserve and smelt at 700°C for 10min, so that...

Embodiment 2

[0029] The invention provides a smelting process of a carbon nanotube reinforced aluminum matrix composite material, comprising the following steps:

[0030] (1) Weigh a certain amount of 50g Na 3 AlF 6 , 50g of carbon nanotubes, and 400g of aluminum powder were mixed and dispersed by ball milling in a planetary ball mill for 5 hours, the ball milling medium was agate balls, and the rotating speed was 400r / min to obtain a carbon nanotube-aluminum mixed powder with a mass fraction of carbon nanotubes of 10wt.%. ;

[0031] (2) Put the mixed powder in the mold and cold-press molding under 200MPa pressure to make a prefabricated block of φ60mm×40mm, and obtain a carbon nanotube-aluminum prefabricated block;

[0032] (3) Press the carbon nanotube-aluminum prefabricated block into the molten aluminum through a bell jar, and at the same time, slowly stir the aluminum melt (60r / min), heat-preserve and smelt at 750°C for 10min, so that the prefabricated block dissolves and enters the...

Embodiment 3

[0034] The present invention provides a smelting process of carbon nanotube reinforced aluminum-based composite material, which is basically the same as in Example 1, except that the smelting aid is KBF 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com