Silicone rubber self-adhesive tape and preparation method thereof

A self-adhesive tape, silicone rubber technology, applied in the direction of adhesives, polymer adhesive additives, film/flake adhesives, etc. The effect of hardness and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example provides a method for preparing a silicone rubber self-adhesive tape, including the following steps:

[0045] S1: adding 107 silica gel, part of the boron-based tackifier and structure control agent into the kneader according to the proportion and kneading to obtain the first rubber compound;

[0046] S2: mixing silica gel, filler and remaining boron-based tackifier according to the ratio for the first mixing;

[0047] S3: Add the spare rubber material obtained in step S1 to the rubber material in step S2, and perform the second mixing to obtain the second rubber material;

[0048] S4: Extrude after mixing the vulcanizing agent and the second rubber compound obtained in step S3 according to the proportion, to obtain the third rubber compound;

[0049] S5: vulcanize the third rubber material obtained in step S4, extrude it, and wind it up to obtain the silicone rubber self-adhesive tape.

[0050] In step S1, the kneading temperature is 70-130° C., and the ...

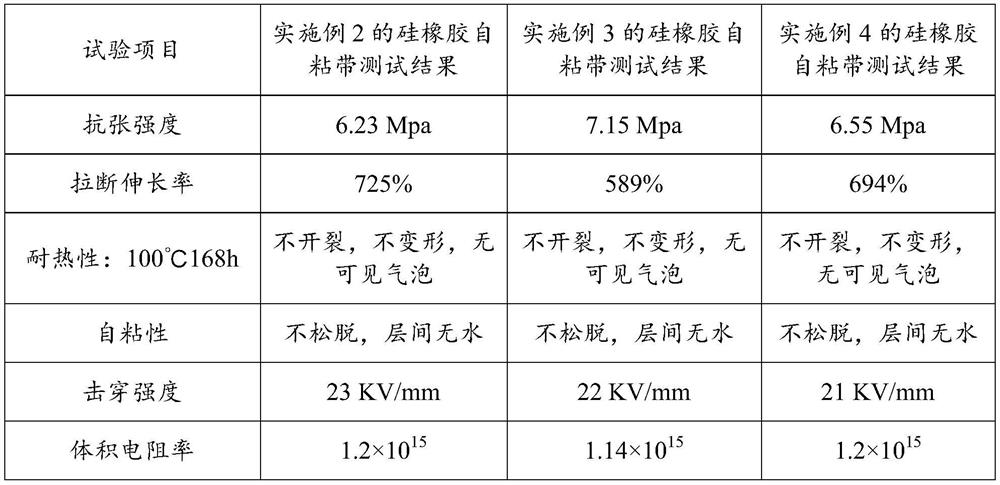

Embodiment 2

[0056] This example adopts the preparation method of Example 1 to prepare a silicone rubber self-adhesive tape, and the preparation raw materials contain:

[0057] 50° mixing silica gel: 100 parts, 107 (600,000 molecular weight) silica gel: 100 parts, borate ester: 10 parts, filler: 50 parts, structure control agent: 4 parts, vulcanizing agent: 1.5 parts.

[0058] Wherein, the filler is fumed white carbon black. The structure control agent is methyl phenyl methoxy silicone oil. The vulcanizing agent is double two four.

Embodiment 3

[0060] This example adopts the preparation method of Example 1 to prepare a silicone rubber self-adhesive tape, and the preparation raw materials contain:

[0061] 50° mixing silica gel: 100 parts, 107 (600,000 molecular weight) silica gel: 100 parts, boric acid: 10 parts, filler: 50 parts, structure control agent: 4 parts, vulcanizing agent: 1.5 parts.

[0062] Wherein, the filler is fumed white carbon black. The structure control agent is methyl phenyl methoxy silicone oil. The vulcanizing agent is double two four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com